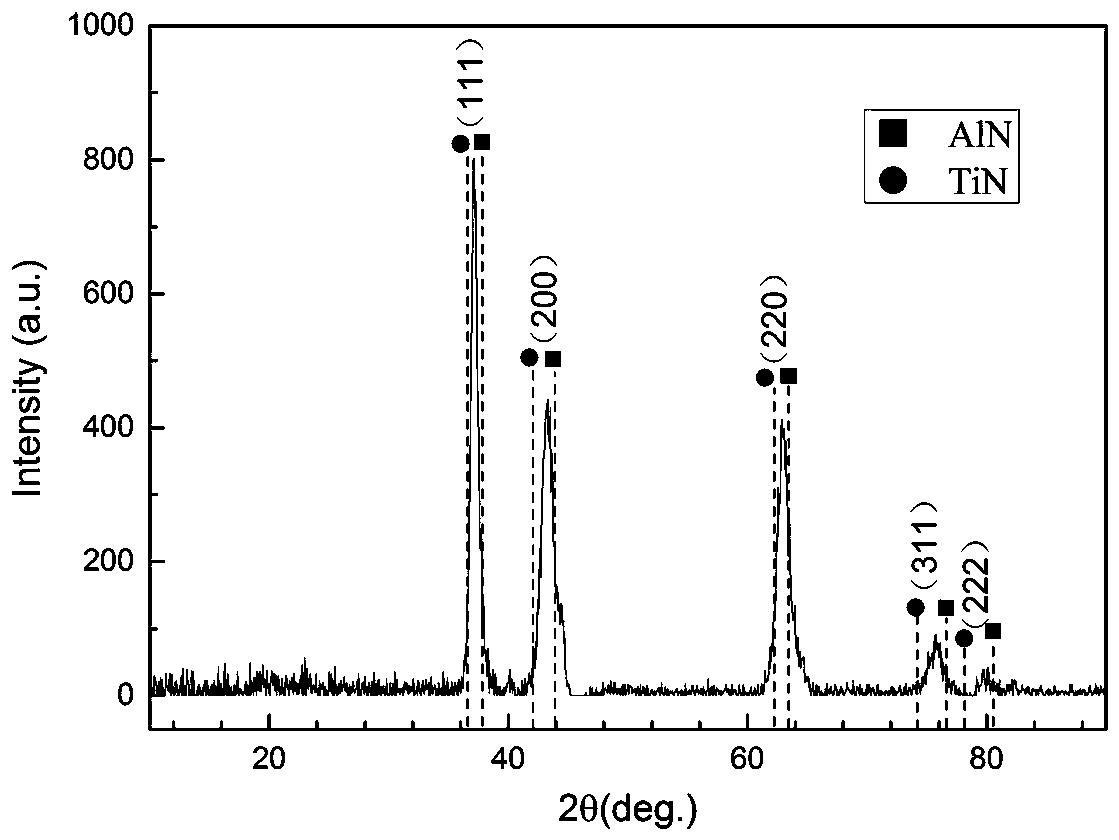

A kind of Altin composite coating with high Al content and preparation method

A technology of Al content and coating, which is applied in the field of preparation of AlTiN composite coatings, can solve the problems of reducing coating hardness, elastic modulus and other mechanical properties, and achieve good wear resistance, strong practicability and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, an AlTiN coating is deposited on a polished high-speed steel sheet, and the sample size is 25×30×1 mm. The substrate was ultrasonically cleaned in acetone, alcohol, and distilled water for 20 minutes, then dried with high-purity nitrogen, and then placed on the sample rack facing the target in the vacuum chamber. The rotation speed of the turntable was selected as 10 r / min. The target base distance is 150 mm. The coating process was carried out on an AIP-650 arc ion coating machine. The target materials were pure metal Ti and Al (both with a purity of 99.9 wt.%), and the working gas and reaction gas were respectively high-purity Ar and N. 2 (The purity is 99.999%).

[0023] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Below Pa; turn on the heating system, raise the temperature to 400 ℃, then pass 80 sccm of Ar gas in the vacuum chamber until the pressure in the coating chamber reaches 1 Pa, apply a negative bias of ...

Embodiment 2

[0030] In this example, an AlTiN coating is deposited on a polished cemented carbide substrate YG8, and the sample size is 25×25×2 mm. The substrate was ultrasonically cleaned in acetone, alcohol, and distilled water for 20 min, then dried with high-purity nitrogen, and then placed on the sample rack facing the target in the vacuum chamber. The base distance is 150 mm. The coating process is carried out on an AIP-650 arc ion coating machine. The target materials are pure metal Ti and Al (both with a purity of wt. 99.9%), and the working gas and reaction gas are respectively Ar and N. 2 (The purity is 99.999%).

[0031] First, the background vacuum of the vacuum chamber is evacuated to 1.0×10 -3 Below Pa. Turn on the heating system, raise the temperature to 450 °C, and then pass 100 sccm of Ar gas into the vacuum chamber until the pressure in the coating chamber reaches 1 Pa, apply a negative bias of -800 V, and turn on 4 pure Ti targets (the target current is selected as 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com