Fully-automatic high rail type ABS automobile part production line

A technology for auto parts and production lines, applied in the direction of conveyor objects, conveyor control devices, metal material coating technology, etc., can solve the problems of low production line efficiency, low production efficiency, high maintenance costs, etc. The effect of large space and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

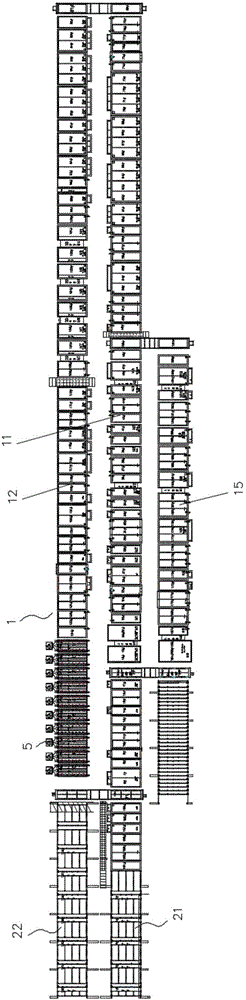

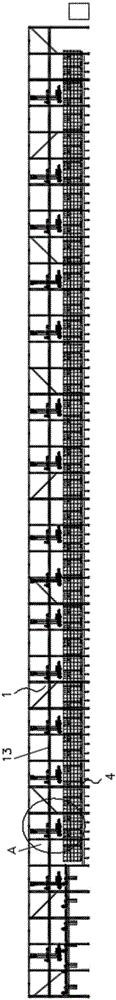

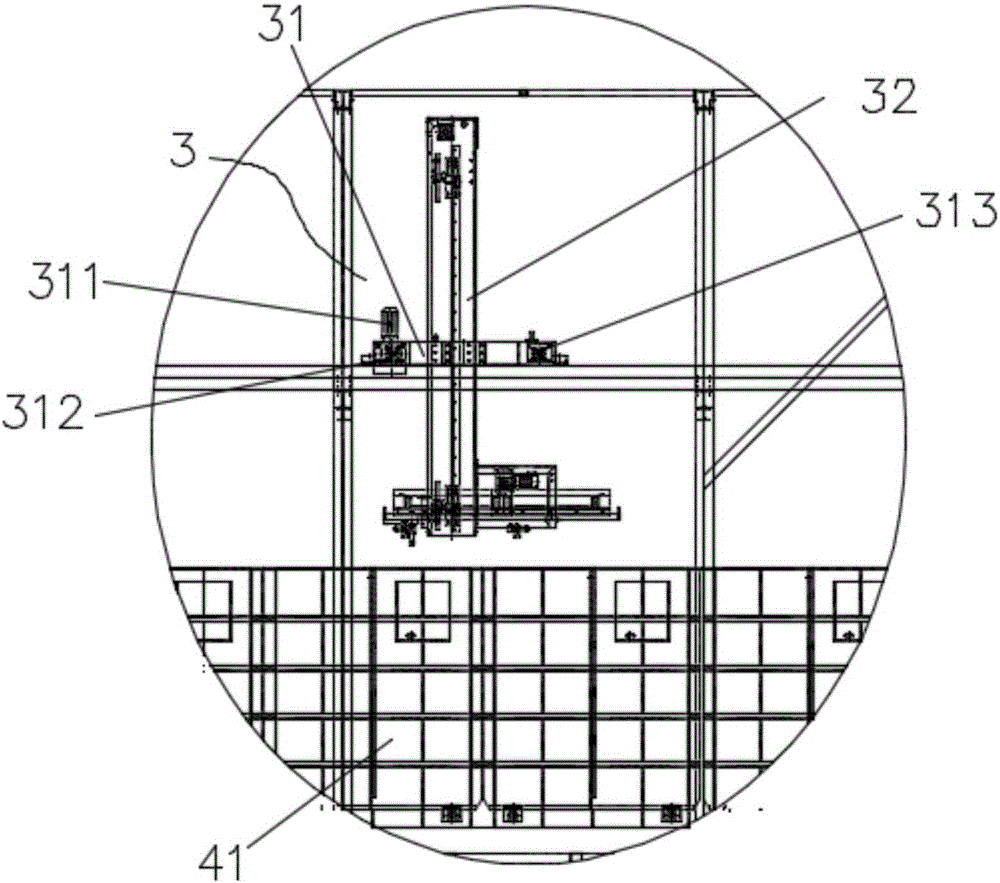

[0026] Examples, see Figure 1 to Figure 5 , the fully automatic high-rail type ABS auto parts production line provided by the present embodiment includes a U-shaped structure production line 1, the production line 1 is provided with a feeding device 21, a transfer device and a feeding device 22, and the production line 1 includes a frame , the frame is provided with a traversing track 13, and several mechanical boom lifting vehicles 3 are movably arranged on the traversing track 13 in the frame; a plurality of stations 4 are also provided in the frame, so Described station 4 is the trough body 41 of stainless steel or steel welding; Described frame comprises left production line frame 11, right production line frame 12 and side production line frame 15, and described feeding device 21 is arranged on left production line frame 11 The front end of the workpiece transportation direction, the unloading device 22 is arranged on the tail end of the workpiece transportation directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com