Preparation device and method for composite plate hammer

A composite material plate and preparation device technology, which is applied in the field of plate hammer preparation devices, can solve the problems of uneven distribution of ceramic particles, fragile and detached ceramics, weak bonding between ceramics and substrates, etc., and achieves enhanced wear resistance, no Shrinkage defects, smooth appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

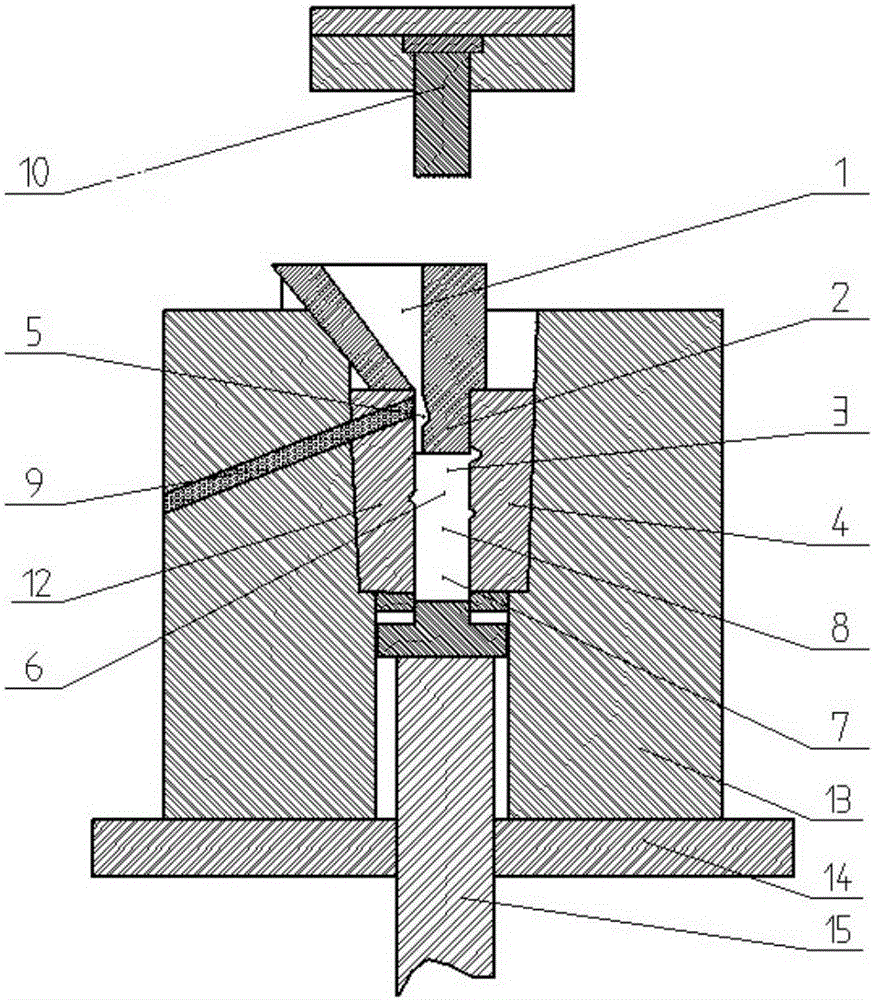

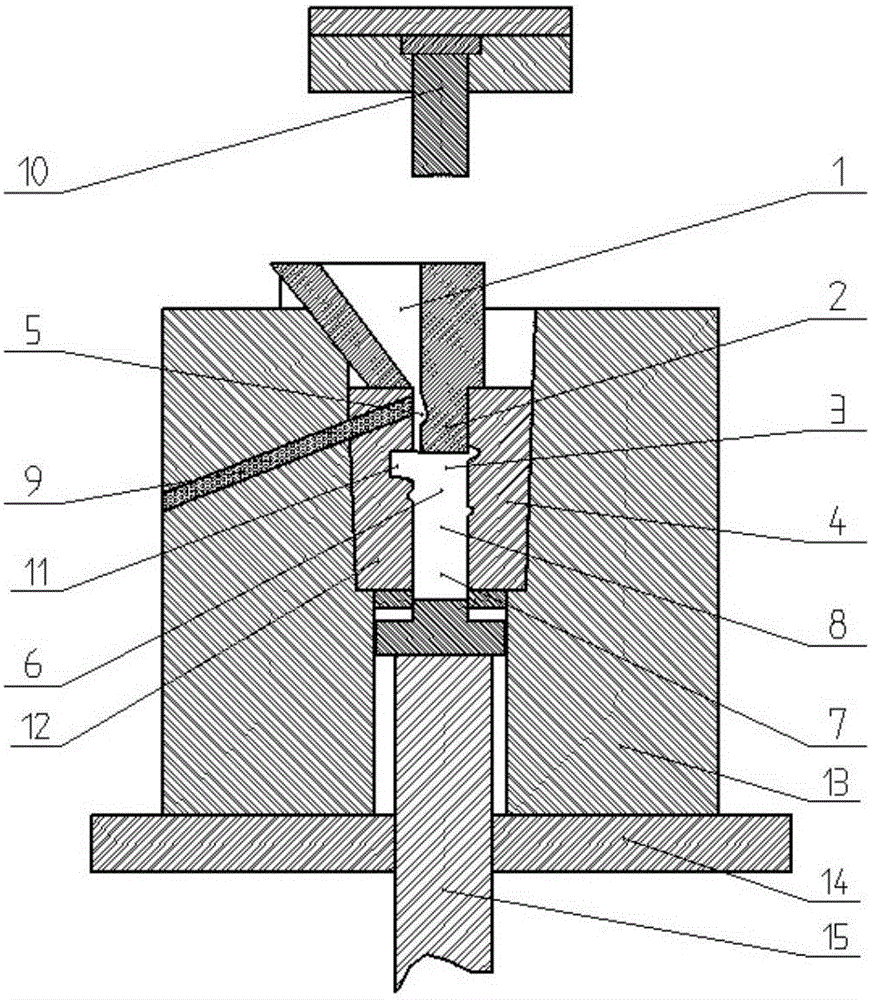

[0047] Example 1 - high manganese steel + corundum blow bar

[0048] This embodiment discloses a method for preparing a corundum particle-reinforced high manganese steel composite blow bar. The basic principles and required devices of the method are as described above.

[0049] Its concrete preparation process comprises steps:

[0050] S1 Preheating: Preheat the blow bar cavity 3 and the ceramic particle cavity 9 to 200°C, and preheat the corundum particles to 1000°C;

[0051] S2 filling ceramic particles: adding preheated corundum particles into the ceramic particle cavity 9, the average particle size of the corundum particles is 2mm;

[0052] S3 Place the sprue cup: place the sprue cup 1 directly above the blow bar cavity 3, the left boundary of the outlet is flush with the left wall of the blow bar cavity 3, and the baffle plate 2 on the right side of the sprue cup 1 Extend into the sprue cavity 5;

[0053] S4 Mixing with flow: While pouring high manganese molten steel w...

Embodiment 2

[0057] Example 2 - high chromium cast iron + zirconia blow bar

[0058] This example discloses a method for preparing a zirconia particle reinforced high-chromium cast iron composite blow bar. The basic principles and required devices of the method are as described above.

[0059] Its specific preparation process includes:

[0060] S1 Preheating: preheat blow bar cavity 3 and ceramic particle cavity 9 to 250°C, and preheat zirconia particles to 1200°C;

[0061] S2 filling ceramic particles: adding preheated zirconia particles into the ceramic particle chamber 9, the average particle size of the zirconia particles is 2mm;

[0062] S3 Place the sprue cup: place the sprue cup 1 directly above the blow bar cavity 3, the left boundary of the outlet is flush with the left wall of the blow bar cavity 3, and the baffle plate 2 on the right side of the sprue cup 1 Extend into the sprue cavity 5;

[0063] S4 Mixing with the flow: while pouring the high chromium cast iron liquid with ...

Embodiment 3

[0067] Example 3 - high chromium cast iron + ZTA blow bar

[0068] This embodiment discloses a method for preparing a ZTA particle reinforced high-chromium cast iron composite blow bar. The basic principle and required devices of the method are as described above.

[0069] Its specific preparation process includes:

[0070] S1 Preheating: Preheat the blow bar cavity 3 and the ceramic particle cavity 9 to 150°C, and preheat the ZTA particles to 800°C;

[0071] S2 Filling with ceramic particles: adding preheated ZTA particles into the ceramic particle chamber 9, the average particle size of the ZTA particles is 2 mm;

[0072] S3 Place the sprue cup: place the sprue cup 1 directly above the blow bar cavity 3, the left boundary of the outlet is flush with the left wall of the blow bar cavity 3, and the baffle plate on the right side of the sprue cup 1 extends into the sprue cavity 5;

[0073] S4 Mixing with flow: While pouring the high chromium cast iron liquid with a superheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com