Method for extracting functional sweetener from malus plant

A technology of sweetener and Malus, which is applied in the direction of food extraction, food ingredients containing natural extracts, food ingredients as taste improvers, etc. It can solve the problems of small distribution area, increased cost, and less planting amount of plants of the genus Licorice , to achieve the effect of low cost, good compatibility and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

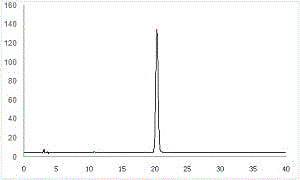

Embodiment 1

[0019] After the treated fruit or fruit residue of Malus is dried by heating and / or freezing and reducing pressure, it is soaked in an aqueous alcohol solution, heated and / or pressurized, and moderately stirred at the same time to increase the leaching rate. After the leaching is completed, the liquid part is concentrated by heating and / or reduced pressure, and then chromatographed with a macroporous resin, eluted with an aqueous alcohol solution, and the components containing the target compound are collected, and concentrated again using a high-speed countercurrent chromatograph. For fine separation, the configured solvent system is injected into the instrument in sequence, and the flow rate is controlled at a certain speed, and the components containing the target compound are collected, fully dried to obtain the sweetener composition, and the sweetener composition is detected by high performance liquid chromatography species trilobatin content.

Embodiment 2

[0021] After the stem or leaf of the treated Malus plant is dried by heating and / or freezing and reducing pressure, it is soaked in an aqueous alcohol solution, heated and / or pressurized, and moderately stirred at the same time to increase the leaching rate. After the leaching is completed, the liquid part is concentrated by heating and / or reduced pressure, and then a chromatographic column packed with polyamide with a certain particle size is used for preliminary separation, and an aqueous alcohol solution is used for elution, and the components containing the target compound are collected and concentrated. Afterwards, gel column chromatography is used for fine separation to obtain a solution containing the sweetener composition, which is dried and crystallized to obtain the sweetener composition, and the content of trilobatin in the sweetener composition is detected by high performance liquid chromatography.

[0022] Non-limiting examples of treatments for Malus plants suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com