Propylene-based resin foam particle and foam particle molded body

A technology of acrylic resin and expanded particles, which is applied in the direction of coating, etc., can solve the problems of difficult forming and processing, and achieve the effects of excellent fusion, excellent heat resistance, and excellent secondary foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1 and comparative example 2

[0176] 1. Selection of low melting point propylene resin (resin a1) for the core layer

[0177] 1) Low melting point propylene resin 1

[0178] An ethylene-propylene random copolymer (ethylene content 2.8% by weight, melting point 135° C., melt flow rate 8 g / 10 minutes) obtained by polymerization in the presence of a metallocene polymerization catalyst was used.

[0179] 2) Low melting point propylene resin 2

[0180] An ethylene-propylene random copolymer (ethylene content 2.6% by weight, melting point 137° C., melt flow rate 7 g / 10 min) obtained by polymerization in the presence of a metallocene-based polymerization catalyst was used.

[0181] 3) Low melting point propylene resin 3

[0182] An ethylene-propylene random copolymer (ethylene content 4.0% by weight, melting point 138° C., melt flow rate 8 g / 10 min) obtained by polymerization in the presence of a Ziegler-Natta type polymerization catalyst was used.

[0183] 2. Selection of high melting point propylene resin (r...

Embodiment 6

[0247] In the manufacture of the expanded propylene resin particle molded body, except that a flat plate molding die with a length of 200 mmⅹ a width of 250 mm×a thickness of 50 mm is used, and the molding pressure is set to 0.14 MPa (G), other conditions are the same as in the above-mentioned embodiment 1, and An expanded particle molded body was obtained. Table 3 shows the physical properties of the expanded beads and expanded bead molded body.

[0248] [Table 2]

[0249] Table 2

[0250]

[0251] *1) Amount based on 100 parts by weight of the total of cladding layer and core layer

[0252] [table 3]

[0253]

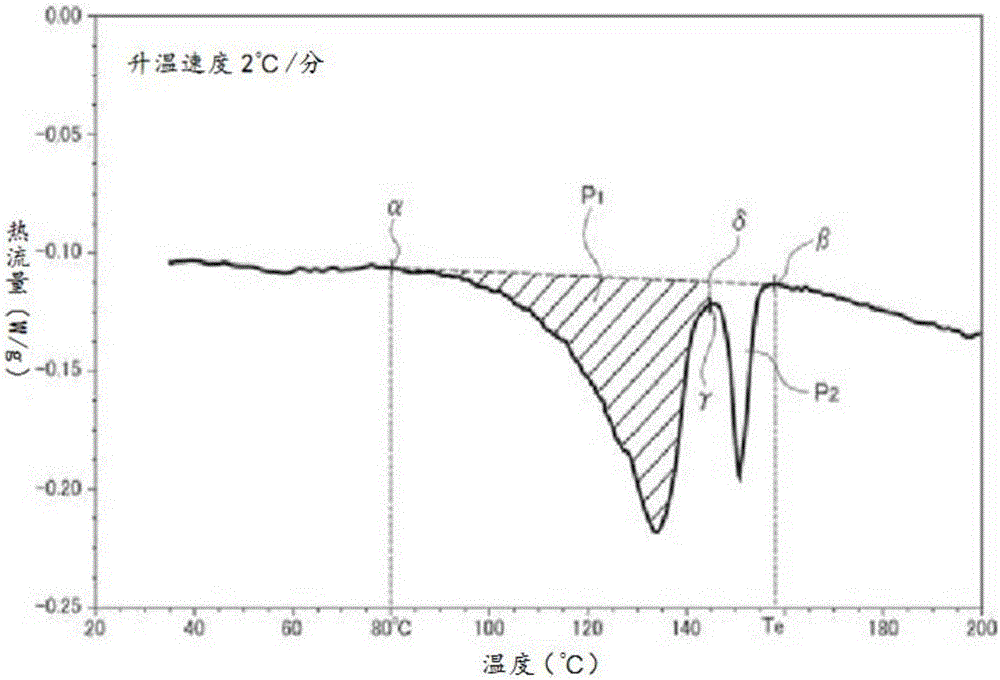

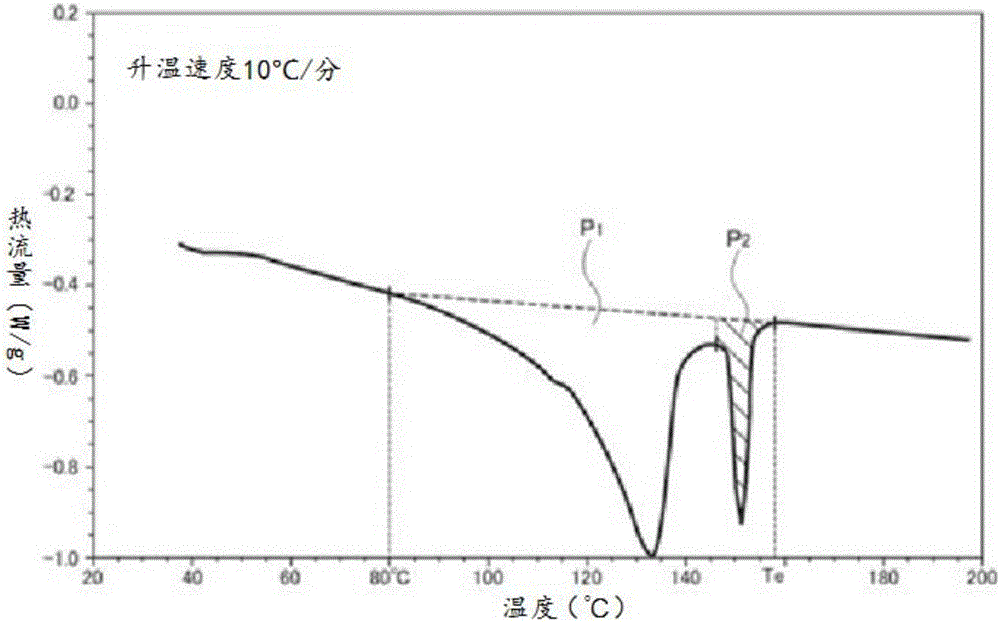

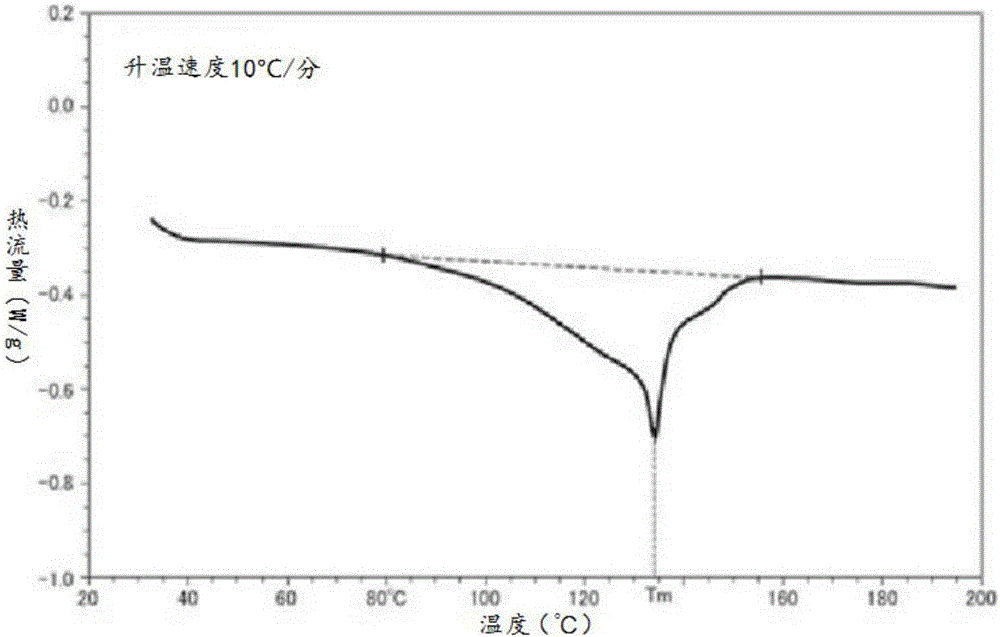

[0254] In Table 3, [Percentage of Main / Full] is a value calculated according to the following method. According to the heat flux differential scanning calorimetry measurement, the "main endothermic peak heat" column and "full endothermic peak heat" in Table 3 are obtained from the first DSC curve obtained when the expanded particles are heated from normal te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com