Testing mechanism for concrete creep under corrosion action, application and creep testing method

A technology of corrosion action and testing mechanism, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as erosion, and achieve the effect of simple loading, convenient operation, and important engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

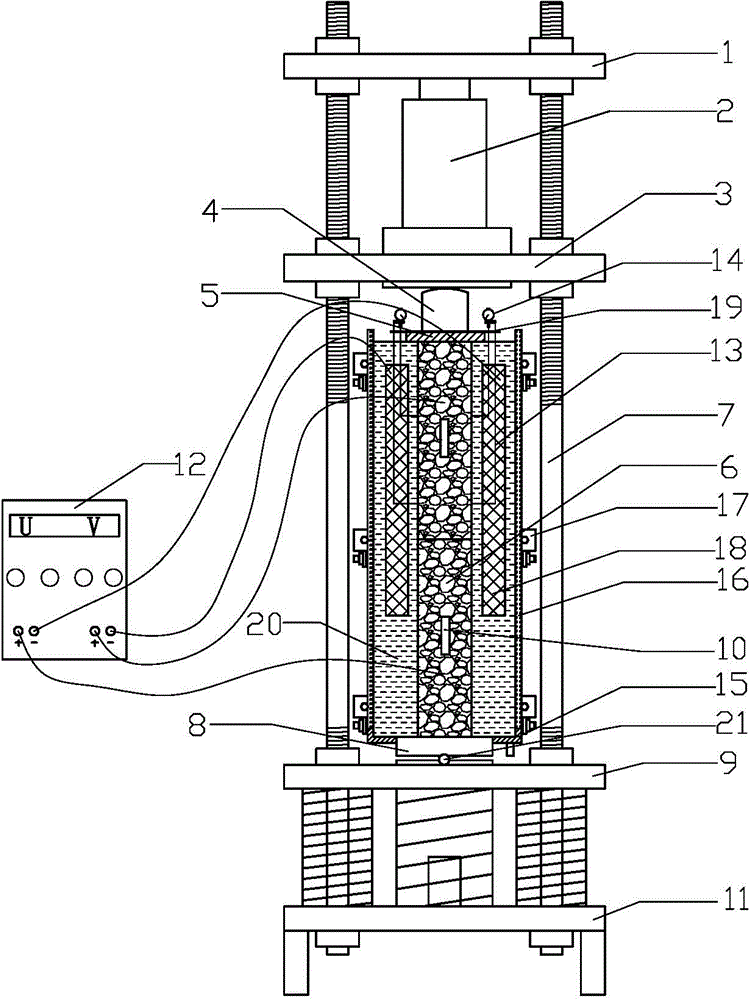

[0024] Depend on figure 1 As can be seen, a concrete creep test mechanism under corrosion, it comprises the stressed steel plate 5 and the pressure sensor 4 that are installed on the top of the test specimen 6, and the test specimen 6 is installed in the center of the open container filled with the corrosive solution 20; Corrosion solution 20 is provided with conductive metal mesh 18, the steel bar in the test specimen 6 is connected with the positive pole of constant voltage direct current power supply 12, and conductive metal mesh 18 is connected with the negative pole of constant voltage direct current power supply 12, by corrosion solution 20, constant voltage direct current The power supply 12 , the conductive metal mesh 18 and the test piece 6 form an electrochemical corrosion circuit; the dial indicator 14 is installed on the test piece 6 .

[0025] For the convenience of observation, the open container of the present invention includes a bottom tank 15 on which high-st...

Embodiment 2

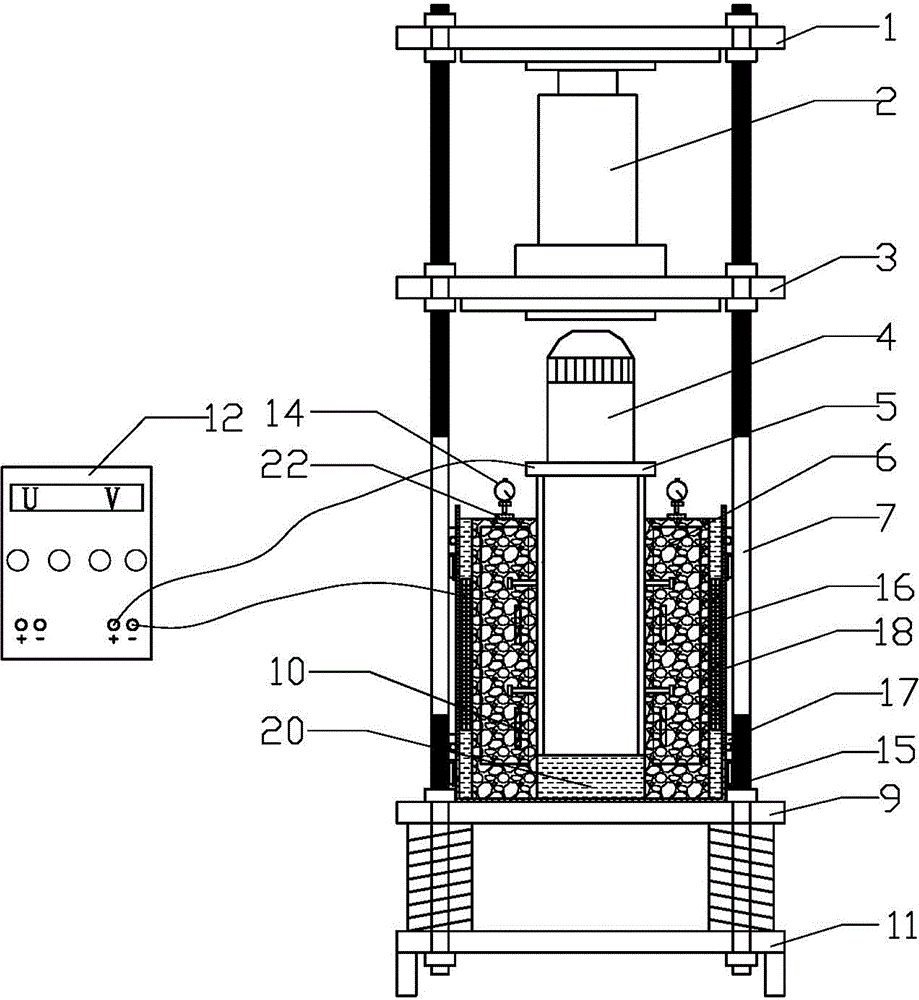

[0044] Depend on figure 2 It can be seen that the test specimen 6 of the present embodiment 2 is a steel-concrete composite structure, and the steel frame and the concrete are connected by bolts; The surface is uneven, and a glass block 22 is arranged between the measuring head and the concrete part on the top of the test specimen 6 . Because the dial gauge 14 is not installed in the corrosion solution 20, therefore, the dial gauge 14 is not needed to be installed outside the corrosion solution 20 without the installation rod, and the corrosion solution 20 is a sodium sulfate solution of 5% mass fraction.

[0045] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com