Generator for pure oxygen compound heat carrier and production method for compound heat carrier

A composite heat carrier and production method technology, applied in the field of generators, can solve the problems of poor mixing effect of pure oxygen and natural gas, unstable combustion, etc., to prevent high-temperature ablation, reduce nitrogen content, increase production capacity and recover rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

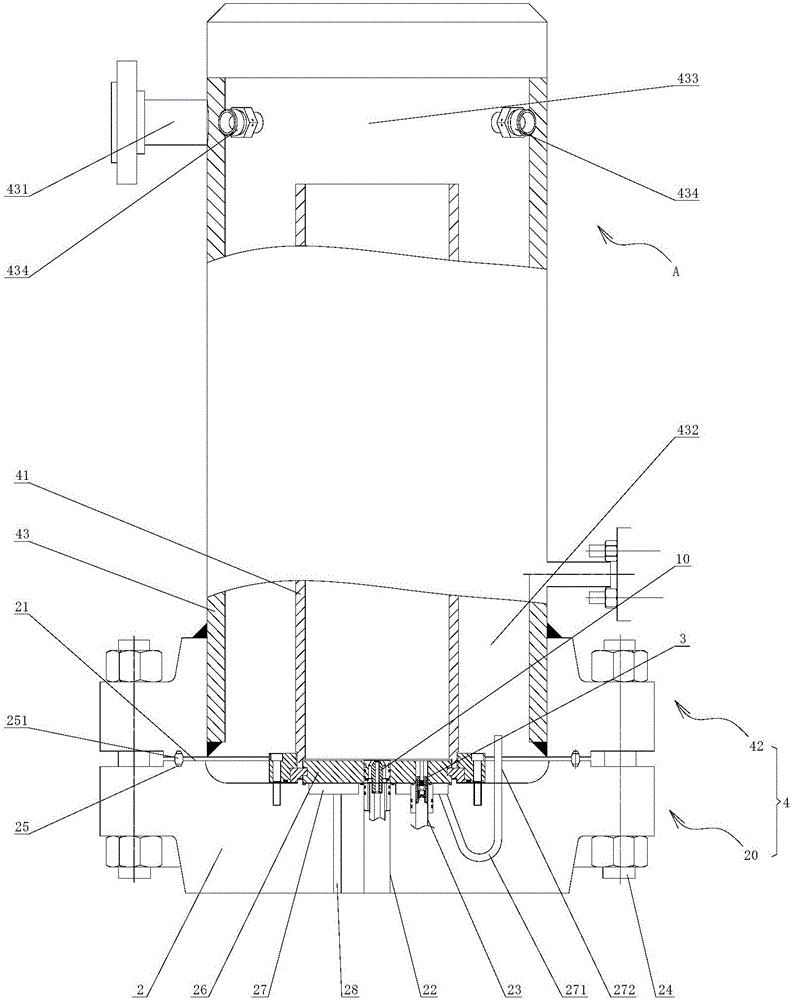

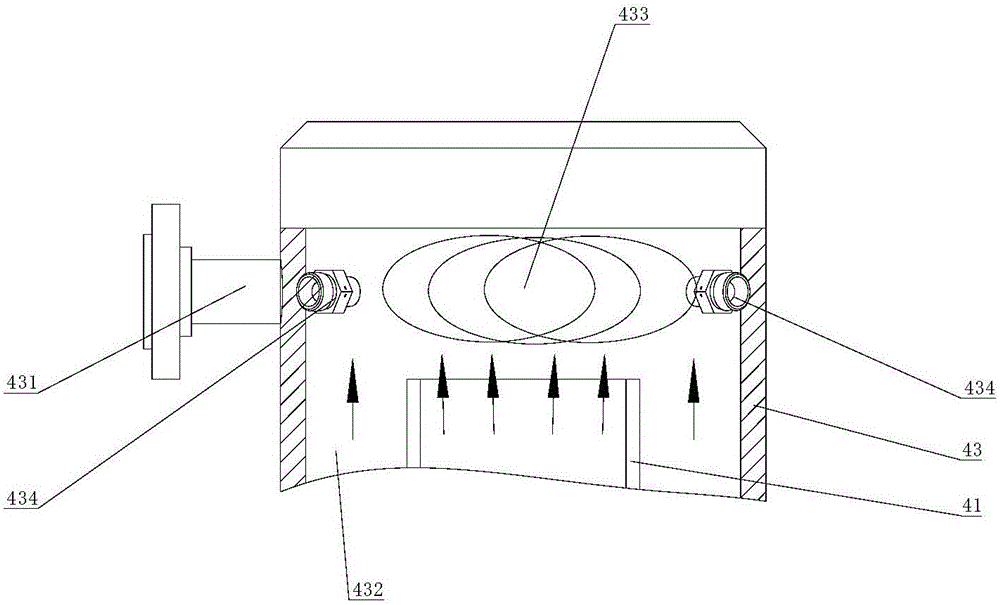

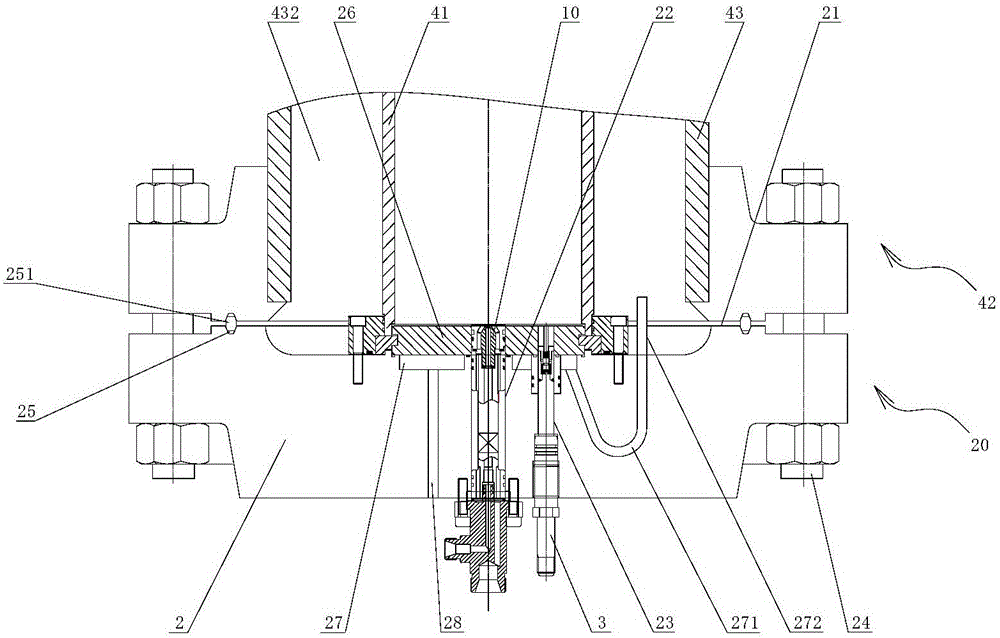

[0043] like Figure 1 to Figure 6As shown, the present invention provides a pure oxygen composite heat carrier generator 4, which includes a generator body 42 and a generator head structure 20, wherein: the generator body 42 includes a combustion chamber 41 and is sleeved in the combustion chamber 41 External steam chamber 43, the upper end of the combustion chamber 41 communicates with the steam chamber 43, and the upper end of the steam chamber 43 is connected with an outlet pipe 431; the generator head structure 20 is connected to the generator body 42 At the lower end, the generator head structure 20 has a head body 2 and a combustion nozzle 10 and an ignition electrode 3 arranged in the head body 2, and the combustion nozzle 10 and the ignition electrode 3 are all connected to the combustion The chamber 41 is oppositely arranged, and the head body 2 is provided with a water inlet passage 28 communicating with the steam chamber 43; wherein, the combustion nozzle 10 has a n...

Embodiment approach 2

[0074] like Figure 1 to Figure 6 As shown, the present invention also provides a composite heat carrier production method of a pure oxygen composite heat carrier generator, the composite heat carrier production method is the composite heat carrier production method of the pure oxygen composite heat carrier generator in Embodiment 1, the The structure, working principle and beneficial effects of the pure oxygen composite heat carrier generator described above are the same as those in Embodiment 1, and will not be repeated here. Described composite heat carrier production method comprises the steps:

[0075] a) Inject pure oxygen and natural gas into the combustion chamber 41 of the generator body 42 through the combustion nozzle 10, and inject water into the steam chamber 43 of the generator body 42 through the water inlet channel 28 of the generator head structure 20;

[0076] b) Turn on the ignition electrode 3, the pure oxygen and the natural gas ejected from the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com