400MPa-level vanadium-containing anti-seismic anti-corrosion rebar and production method thereof

A production method and corrosion-resistant technology, applied in the fields of metallurgy and building materials, can solve the problems of high production cost of stainless steel bars, accelerated corrosion of steel bars, and limited corrosion resistance of galvanized steel bars, so as to improve strength and hydrogen corrosion resistance, and stabilize Corrosion resistance and mechanical properties, and good performance of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment;

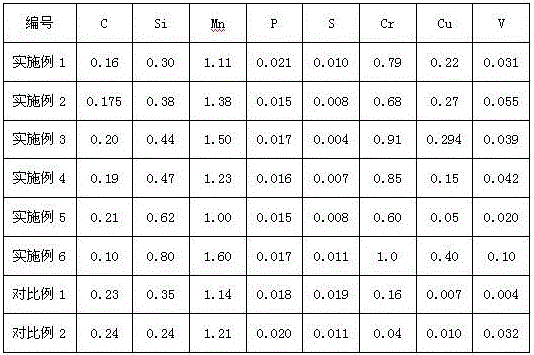

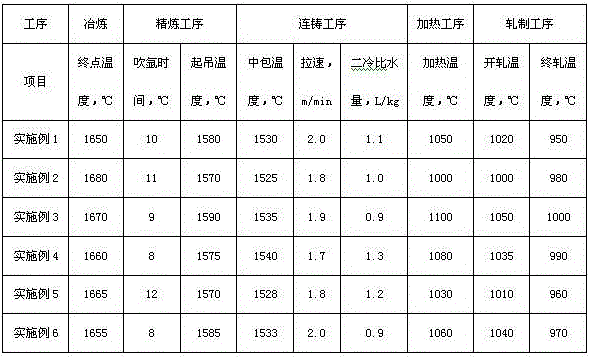

[0030] The technological process of the 400MPa vanadium-containing anti-seismic and corrosion-resistant steel bars in Examples 1-6 is: converter or electric furnace smelting→ladle microalloying→external refining→continuous casting→slab heating→rolling→cooling bed air cooling, specific operation steps for:

[0031] (1) Smelting: decarburization and dephosphorization smelting of molten iron together with steel scrap, copper block or copper plate, slagging material, etc., wherein copper block or copper plate is used for copper alloying, and the weight percentage of carbon at the end point is controlled at 0.06-0.12%. The weight percent content of phosphorus is P≤0.020%, and the end point temperature is controlled at 1650-1680°C.

[0032] (2) Ladle micro-alloying: In step (1) during the tapping process, silicon-manganese alloy or ferromanganese, ferrosilicon, ferrochrome and vanadium-ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com