Method for preparing high-purity silver powder from silver-rich residue containing high selenium and tellurium

A technology of high selenium and silver powder, applied in the direction of improving process efficiency, etc., to achieve the effect of good industrial application prospect, high purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

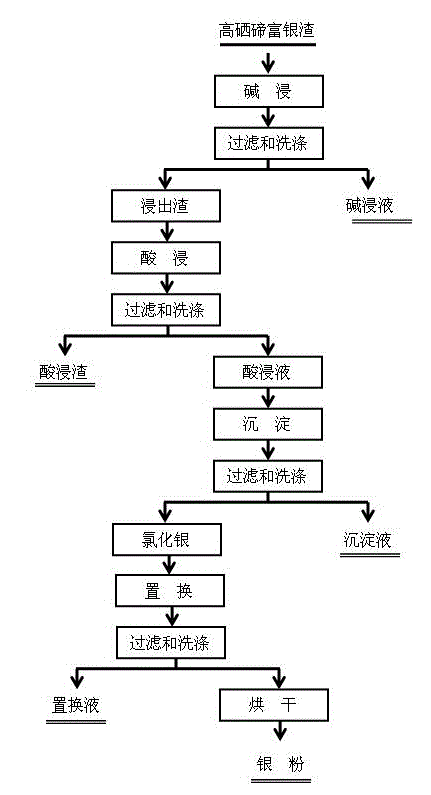

[0026] See attached figure 1 , Conditions: 1000 grams of high-selenium-tellurium-rich silver slag, the amount of sodium hydroxide added is 30% of the slag weight, slowly heated to 85 ° C, the stirring speed is 250 rpm, the leaching time is 4 hours, filtered and washed to obtain alkali immersion solution and Alkali leaching residue, wherein the alkali leaching solution is used as the raw material for extracting selenium and tellurium; the alkali leaching residue is leached with nitric acid, the amount of nitric acid added is 50% of the slag weight, slowly heated to 85°C, the stirring speed is 250rpm, and the leaching time is 5h. , filtered and washed to obtain acid leaching solution and acid leaching residue respectively, adding sodium chloride to the acid leaching solution to selectively precipitate silver to obtain silver chloride precipitation, after filtering and washing, add deionized water, and add high-purity zinc as a displacing agent Silver powder is replaced to obtain...

Embodiment 2

[0028] See attached figure 1 , Conditions: 5000 grams of high selenium and tellurium rich silver slag, the amount of sodium carbonate added is 20% of the slag weight, slowly heated to 85 ° C, the stirring speed is 250 rpm, the leaching time is 3 hours, filtered and washed to obtain alkali leaching solution and alkali The leaching residue, wherein the alkali leaching solution is used as the raw material for extracting selenium and tellurium; the alkali leaching residue is leached with nitric acid, the amount of nitric acid added is 40% of the slag weight, slowly heated to 85°C, the stirring speed is 250rpm, and the leaching time is 3h. After the leaching is completed, Filter and wash to obtain acid leaching solution and acid leaching residue respectively. Add hydrochloric acid to the acid leaching solution to selectively precipitate silver to obtain silver chloride precipitation. After filtering and washing, add deionized water and replace it with high-purity iron powder to obta...

Embodiment 3

[0030] See attached figure 1 , Conditions: 10,000 grams of high-selenium, tellurium-rich silver-rich slag, the amount of sodium hydroxide added is 40% of the slag weight, slowly heated to 85°C, the stirring speed is 250rpm, the leaching time is 4h, filtered and washed to obtain alkali leaching solution and alkali leaching residue, in which the near leaching solution is used as the raw material for extracting selenium and tellurium; the alkali leaching residue is leached with nitric acid, the amount of nitric acid added is 60% of the slag weight, slowly heated to 85°C, the stirring speed is 250rpm, the leaching time is 4h, and the leaching is completed Finally, filter and wash to obtain acid leaching solution and acid leaching residue respectively, add hydrochloric acid to the acid leaching solution to selectively precipitate silver, and obtain silver chloride precipitation, after filtering and washing, add deionized water, and add displacing agent sodium borohydride Silver pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com