Deoxidation method and device for converter gas

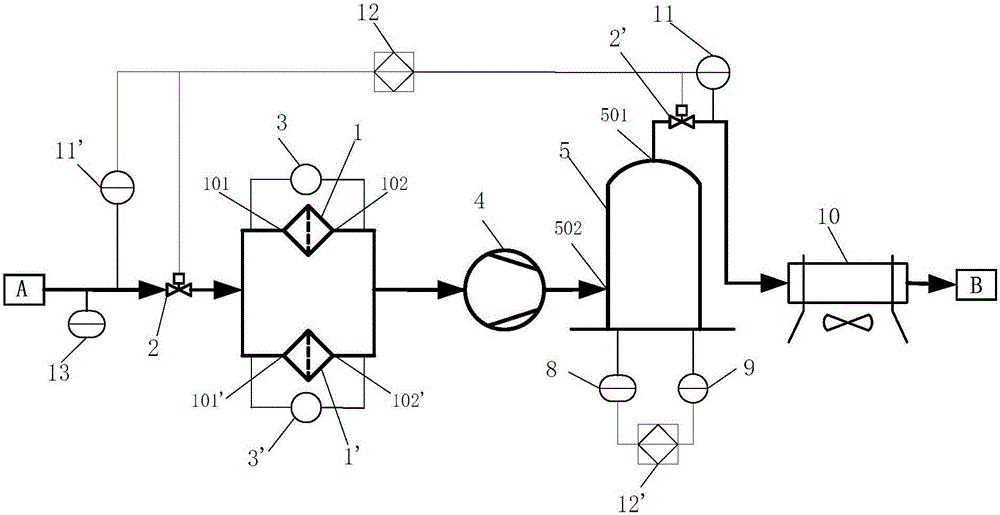

A converter gas and deoxidizer technology, applied in the manufacture of converters, etc., can solve the problems of complex production process and high cost of deoxidizer, and achieve the effect of easy online regeneration, small investment at one time, and increased contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

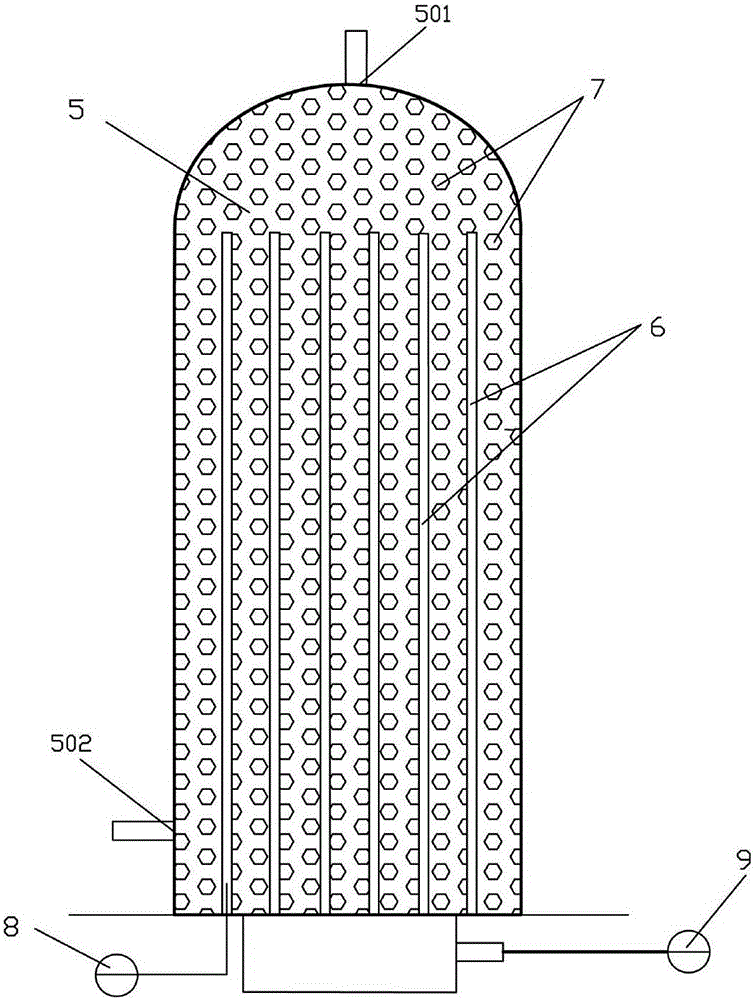

[0049] In this example, the oxygen content in the raw converter gas is 6000ppm, and the dust content is 10mg / Nm 3 . Dust filter 1, 1' reduces the dust content in the converter gas to 3mg / Nm 3 , then the converter gas enters the compressor 4, the gas pressure is compressed to 6bar (G), the compressed converter gas enters the bottom of the deoxidizer 5 from the gas inlet 502 of the deoxidizer 5, and the deoxidizer is filled with copper-plated stainless steel balls, the deoxidizer The heating temperature of the electric heater 6 inside 5 is set at 250°C. After heating, the first oxygen analyzer 11 detects that the oxygen content at the gas outlet 501 of the deoxidizer 5 is 180ppm, and the oxygen removal efficiency reaches 97%, which meets the requirements of the fermentation process. The converter gas discharged from the gas outlet 501 of the deaerator 5 passes through the cooler 10, the temperature drops to room temperature, and then is sent to the downstream microbial anaerobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com