Corrosion-resistant low-temperature-curing cathode electrophoretic paint

A cathodic electrophoresis and electrophoretic paint technology, which is applied in the coating field, can solve the problems that the environmental performance of electrophoretic paint needs to be improved, and achieve the effects of increasing penetration, increasing uniformity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

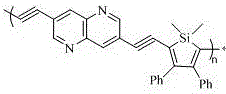

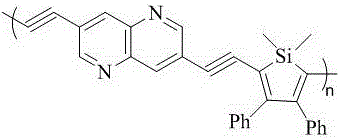

Method used

Image

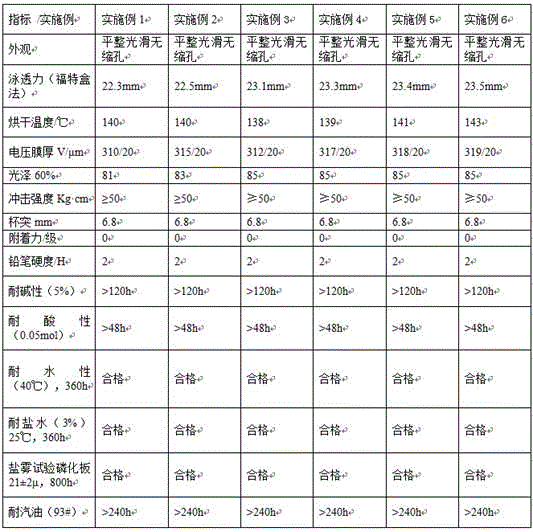

Examples

Embodiment 1

[0074] An anti-yellowing cathodic electrophoretic paint, comprising, in parts by mass, 1 part of color paste, 4 parts of emulsion and 5 parts of deionized water;

[0075] The color paste formula includes 20 parts of main resin, 5 parts of alcohol ether co-solvent, 3 parts of organic acid, 0.3 part of emulsifier, 1 part of composite drier, 30 parts of deionized water, 15 parts of filler, the first solid 3 parts of additives and 6 parts of second solid additives, 6 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a ratio of 1:3:2 by mass; and 7 parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a mass ratio of 1:2:3; and vulcanization in a mass ratio of 1:0.5:1.7 Cottonseed oil T404, bis(2-mercapto-4-n-propylamino-1,3,5-triazine) sulfide and bis(2-mercapto-4-cyclopentylamino-1,3,5-triazine) 8 parts of the third composite regulator composed of sulfide;...

Embodiment 2

[0097] Anti-yellowing cathodic electrophoretic paint, including by mass parts, 2 parts of color paste, 6 parts of emulsion and 5 parts of deionized water;

[0098] The color paste formula includes 30 parts of main resin, 10 parts of alcohol ether co-solvent, 8 parts of organic acid, 0.7 part of emulsifier, 5 parts of composite drier, 40 parts of deionized water, 20 parts of filler, the first solid 7 parts of additives, 1.5 parts of the second solid additive, 9 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerin and polytetrafluoroethylene in a ratio of 1:4:1 by mass; Ratio 1: 7-parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a ratio of 4:1; and vulcanization in a ratio of 1:0.8:1.3 by mass Cottonseed oil T404, bis(2-mercapto-4-n-propylamino-1,3,5-triazine) sulfide and bis(2-mercapto-4-cyclopentylamino-1,3,5-triazine) 14 parts of the third composite regulator composed of sulfide; ...

Embodiment 3

[0121] Anti-yellowing cathodic electrophoretic paint, including by mass parts, 1.2 parts of color paste, 5 parts of emulsion and 6 parts of deionized water;

[0122] The color paste formula includes 25 parts of main resin, 8 parts of alcohol ether co-solvent, 5 parts of organic acid, 0.5 part of emulsifier, 4 parts of composite drier, 35 parts of deionized water, 15-20 parts of filler, the first solid 4 parts of additives and 5 parts of second solid additives and 7 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a ratio of 1:3:1 by mass; 9 parts of the second composite regulator composed of diphenylamine, 2,6-di-tert-butyl and benzotriazole in a ratio of 1:3:2; and vulcanized cottonseed in a ratio of 1:0.7:1.5 by mass Oil T404, bis(2-mercapto-4-n-propylamino-1,3,5-triazine) sulfide and bis(2-mercapto-4-cyclopentylamino-1,3,5-triazine)sulfur 12 parts of the third composite regulator composed of ether; 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com