Liquid-liquid two-phase method for preparing nano cobalt powder

A nano-cobalt and solution technology, applied in metal processing equipment, transportation and packaging, can solve the problems of difficult to control the final form of cobalt powder, complicated process control, and high requirements for equipment vacuum, achieving low cost, simple process, good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

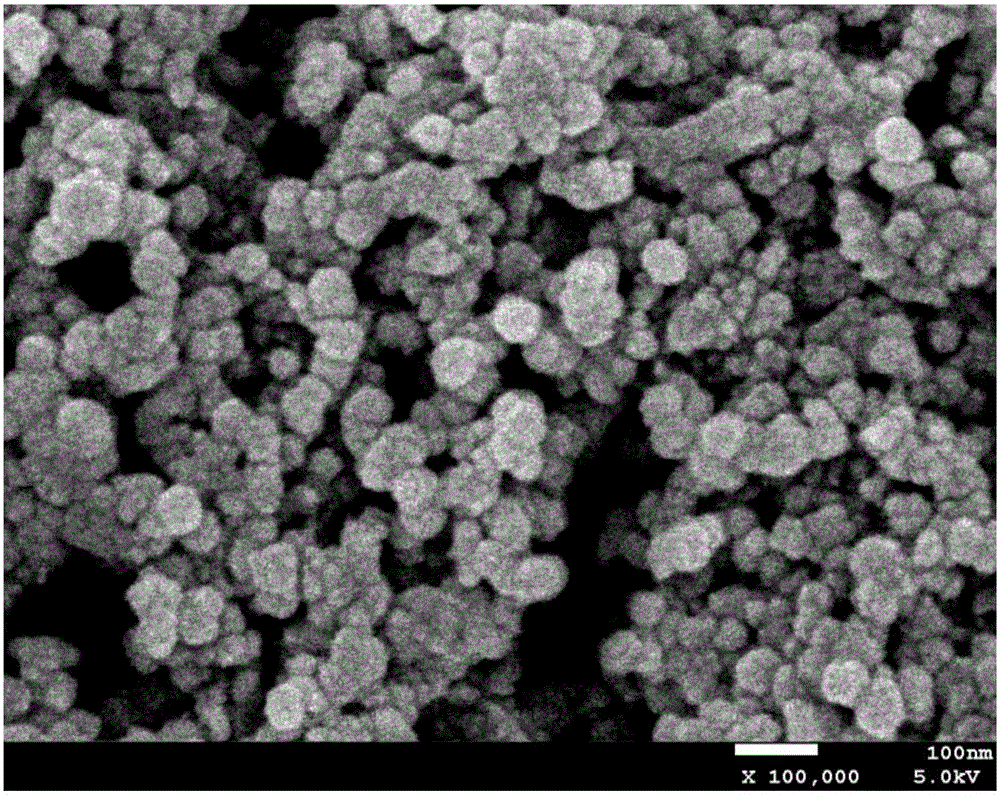

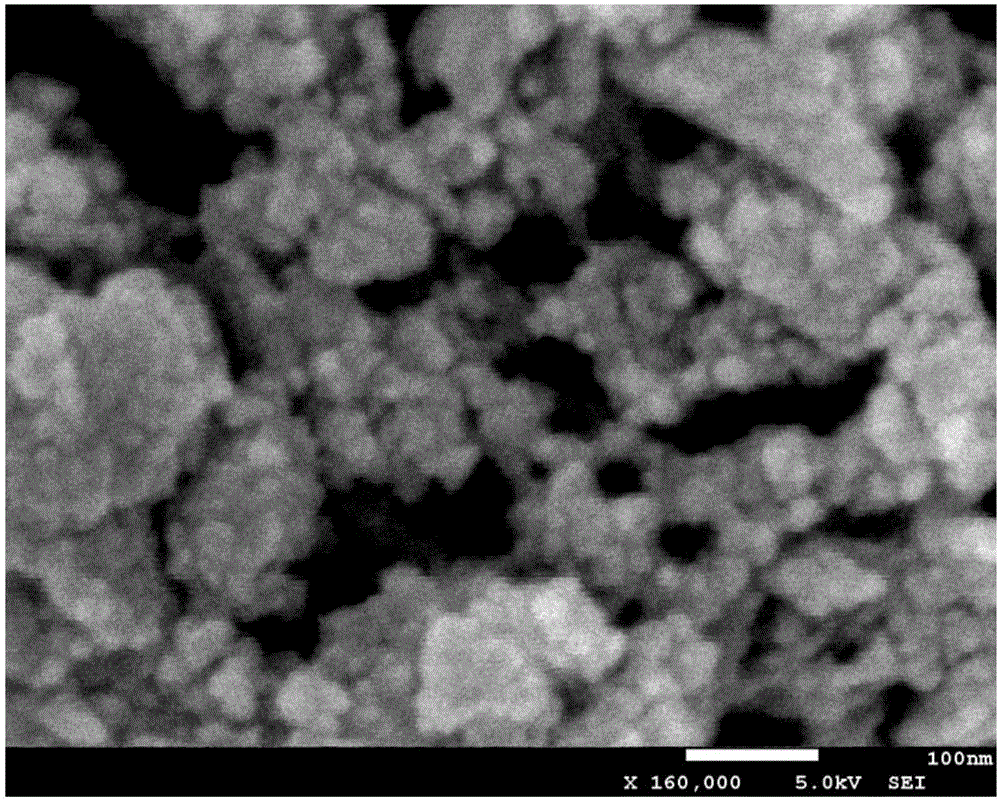

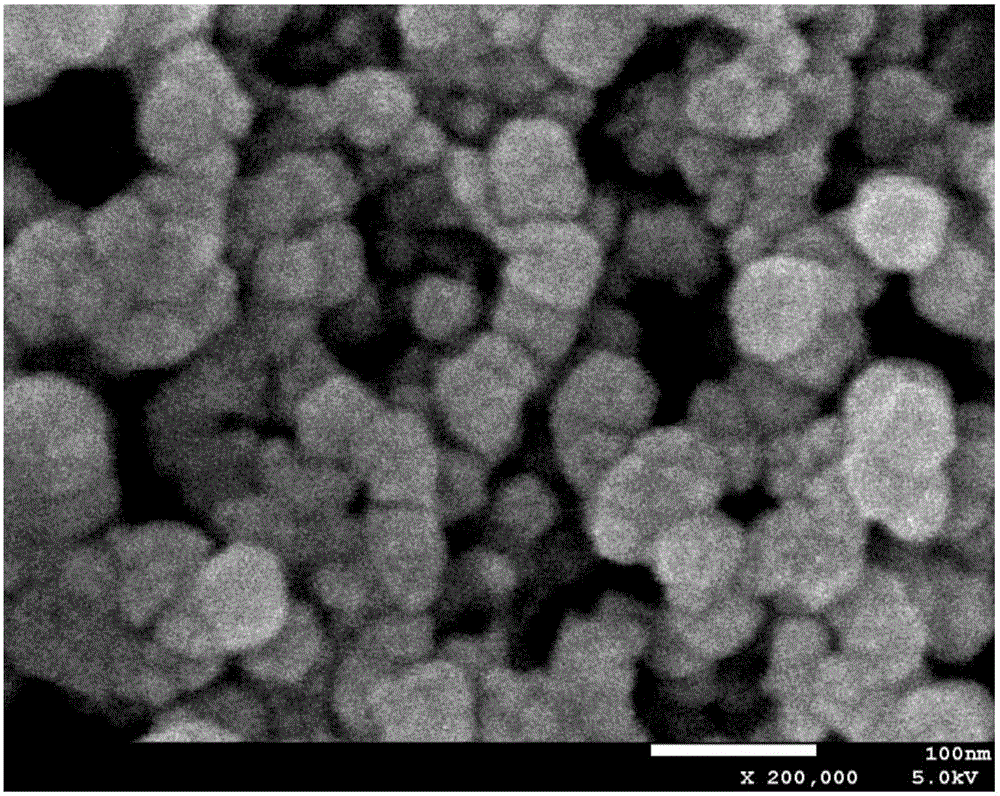

Image

Examples

Embodiment 1

[0037] Dissolve cobalt chloride and sodium lactate in deionized water at 60°C, add stearic acid monoglyceride and stir to dissolve to obtain a 0.08mol / L cobalt complex solution, in which cobalt chloride, sodium lactate and stearic acid monoglyceride The molar mass ratio of the esters is 1:0.8:0.02. Mix n-pentane and n-propanol to form an organic solution, wherein the volume ratio of n-pentane and n-propanol is 1:0.5. Dissolve the cobalt complex solution prepared above in the prepared organic solution, add oleic acid, and stir magnetically until a uniform and stable cobalt microemulsion is formed, wherein the molar ratio of oleic acid to cobalt complex solution is 10 :1, the volume ratio of cobalt complex solution to organic solution is 1:8. Dissolve sodium borohydride and sodium hydroxide solution in deionized water at a molar ratio of 1:1 to prepare a sodium borohydride solution with a concentration of 1 mol / L. Measure the cobalt microemulsion and deionized water prepared a...

Embodiment 2

[0039] Dissolve cobalt sulfate and sodium malate in deionized water at 65°C, and add zinc stearate to stir and dissolve to obtain a 0.10mol / L cobalt complex solution, in which cobalt sulfate, sodium malate and zinc stearate The molar mass ratio is 1:1:0.03. Mix n-hexane and n-butanol to form an organic solution, wherein the volume ratio of n-hexane and n-butanol is 1:0.7. Dissolve the cobalt complex solution prepared above in the prepared organic solution, add sodium lauryl sulfate, and stir magnetically until a uniform and stable cobalt microemulsion is formed, wherein sodium lauryl sulfate is complexed with cobalt The molar ratio of the cobalt complex solution to the organic solution is 12:1, and the volume ratio of the cobalt complex solution to the organic solution is 1:10. Potassium borohydride and sodium hydroxide solution were dissolved in deionized water at a molar ratio of 1:2 to prepare an aqueous solution with a potassium borohydride concentration of 1.1 mol / L. Me...

Embodiment 3

[0041] Dissolve cobalt acetate and sodium citrate in deionized water at 70°C, and add polyvinylpyrrolidone to stir and dissolve to obtain a 0.12mol / L cobalt complex solution, wherein the molar mass of cobalt acetate, sodium citrate and polyvinylpyrrolidone The ratio is 1:1.2:0.03. Mix n-heptane and n-pentanol to form an organic solution, wherein the volume ratio of n-heptane and n-pentanol is 1:0.9. Dissolve the above-prepared cobalt complex solution in the prepared organic solution, add polyglycerol fatty acid ester, and stir magnetically until a uniform and stable microemulsion is formed, wherein the molar ratio of polyglyceryl fatty acid ester and cobalt complex solution The ratio is 13:1, and the volume ratio of cobalt complex solution to organic solution is 1:12. Dissolve sodium borohydride and sodium hydroxide solution in deionized water at a molar ratio of 1:3 to prepare an aqueous sodium borohydride solution with a sodium borohydride concentration of 1.3 mol / L. Measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com