Direct contact type flue gas waste heat recovery device

A flue gas waste heat recovery device technology, applied in direct contact heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problems of large flue gas side resistance, weakened heat exchange capacity, and large flue gas resistance. , to achieve the effect of improving heat exchange efficiency, reducing resistance and ensuring heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

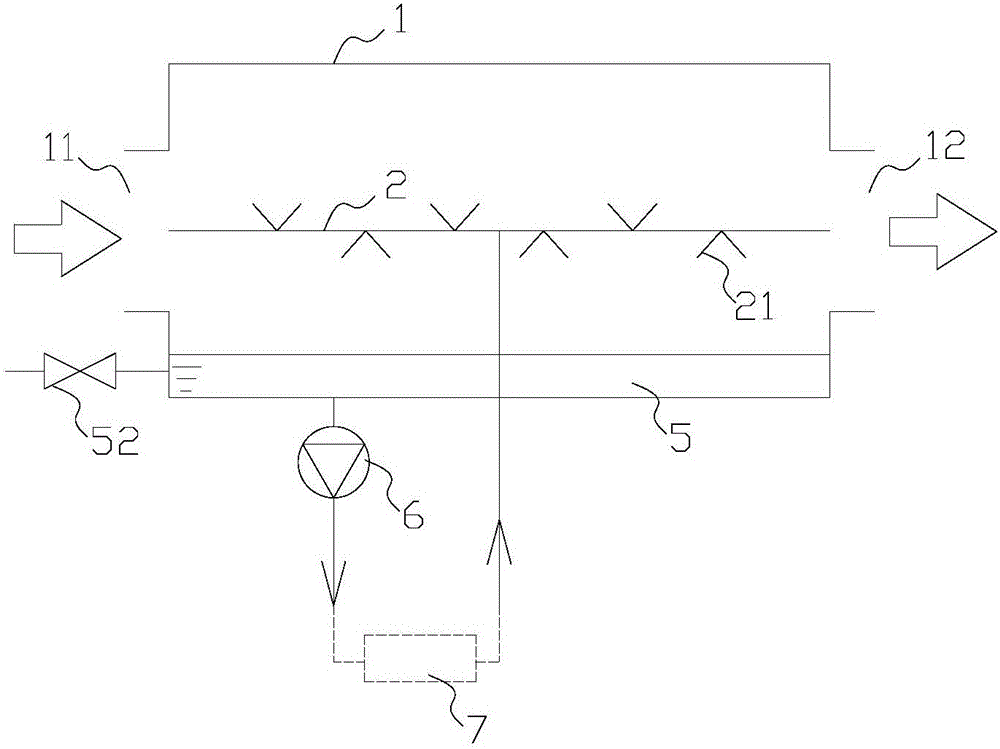

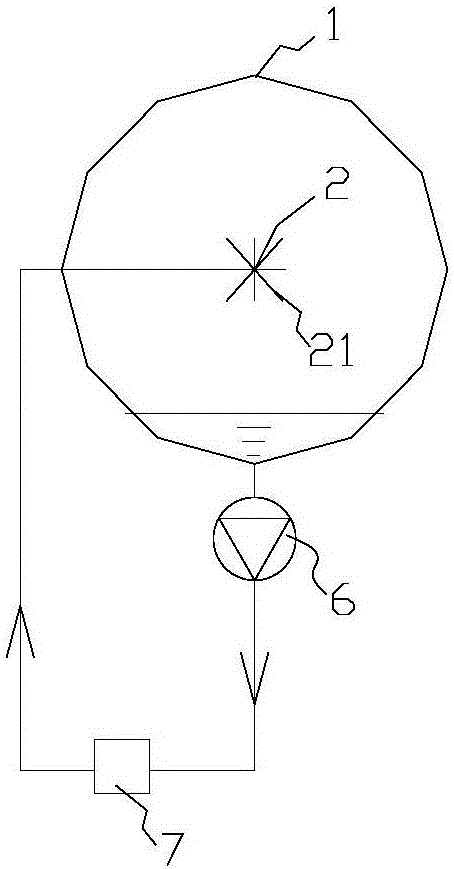

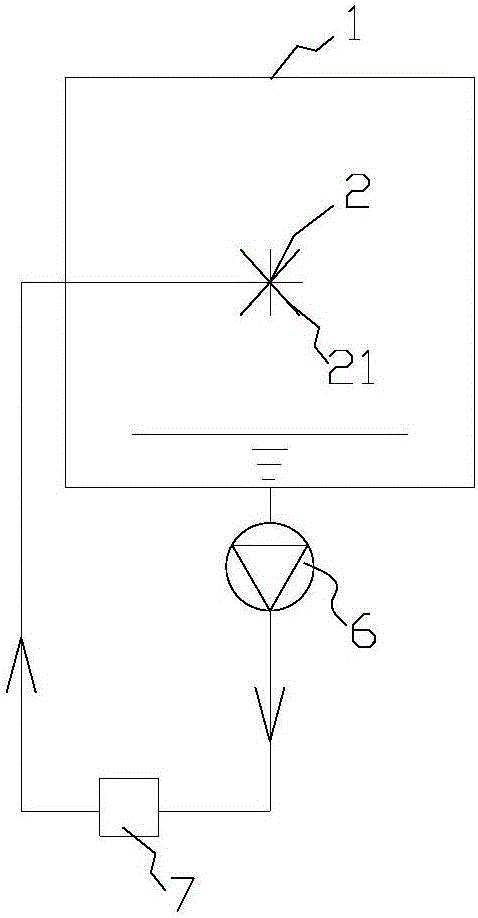

[0052] The core of the present invention is to provide a direct contact flue gas waste heat recovery device, which can not only reduce the collision loss of liquid droplets, reduce the resistance of flue gas, but also reduce the influence of gravity acceleration, prolong the residence time of liquid droplets, improve Mass and heat transfer capabilities, thereby improving the efficiency of flue gas recovery.

[0053]In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] It should be noted that the orientation words "horizontal, vertical, up, down, left, and right" appearing in this article are all established based on the drawings in the specification, and their appearance should not affect the scope of protection of the present invention.

[0055] In a specific embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com