A preparation method of antistatic/luminous dual-function low elastic yarn

A dual-function, antistatic technology, applied in the direction of conductive/antistatic filament manufacturing, rayon manufacturing, filament raw material melting, etc. Poor static electricity and other problems, to achieve the effect of eliminating charge accumulation, high strength, washing resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of rare earth luminous masterbatch: take polyethylene terephthalate resin to dry, add Sr with a mass fraction of 12wt% 0.975 Eu 0.025 al 2 o 4 ·(Al 0.9735 B 0.0015 Dy 0.025 ) 2 o 3 Strontium aluminate rare earth luminous material, dispersant 0.20wt%, lubricant 0.02wt%, mixed by high-speed mixer, added to twin-screw extruder (temperature 285 ℃), melted, water cooled, pelletized to obtain luminous masterbatch, then vacuum dried for later use;

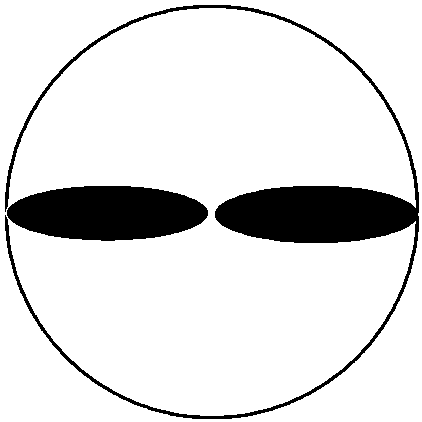

[0031] (2) The preparation method of conductive masterbatch: get polyethylene terephthalate resin to dry, add the rod-shaped conductive particle that mass fraction is 65wt%, dispersant 0.50wt%, lubricant 0.02wt%, mix through high-speed mixer Finally, add it to a twin-screw extruder (at a temperature of 285°C), melt it, cool it with water, and cut it into pellets to obtain a luminous masterbatch, which is then vacuum-dried for later use;

[0032] (3) Preparation of antistatic / luminous dual-function low elast...

Embodiment 2

[0035](1) Preparation of rare earth luminous masterbatch: take polyethylene terephthalate resin to dry, add Sr with a mass fraction of 12wt% 0.975 Eu 0.025 Al 2 o 4 ·(Al 0.9735 B 0.0015 Dy 0.025 ) 2 o 3 Strontium aluminate rare earth luminous material, dispersant 0.20wt%, lubricant 0.02wt%, mixed by high-speed mixer, added to twin-screw extruder (temperature 285 ℃), melted, water cooled, pelletized to obtain luminous masterbatch, then vacuum dried for later use;

[0036] (2) The preparation method of conductive masterbatch: get polyethylene terephthalate resin to dry, add the rod-shaped conductive particle that mass fraction is 65wt%, dispersant 0.50wt%, lubricant 0.02wt%, mix through high-speed mixer Finally, add it to a twin-screw extruder (at a temperature of 285°C), melt it, cool it with water, and cut it into pellets to obtain a luminous masterbatch, which is then vacuum-dried for later use;

[0037] (3) Preparation of antistatic / luminous double-functional low el...

Embodiment 3

[0040] (1) Preparation of rare earth luminous masterbatch: take polyethylene terephthalate resin to dry, add Sr with a mass fraction of 12wt% 0.975 Eu 0.025 Al 2 o 4 ·(Al 0.9735 B 0.0015 Dy 0.025 ) 2 o 3 Strontium aluminate rare earth luminous material, dispersant 0.20wt%, lubricant 0.02wt%, mixed by high-speed mixer, added to twin-screw extruder (temperature 285 ℃), melted, water cooled, pelletized to obtain luminous masterbatch, then vacuum dried for later use;

[0041] (2) The preparation method of conductive masterbatch: get polyethylene terephthalate resin to dry, add the rod-shaped conductive particle that mass fraction is 65wt%, dispersant 0.50wt%, lubricant 0.03wt%, mix through high-speed mixer Finally, add it to a twin-screw extruder (at a temperature of 285°C), melt it, cool it with water, and cut it into pellets to obtain a luminous masterbatch, which is then vacuum-dried for later use;

[0042] (3) Preparation of antistatic / luminous double-functional low e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com