Methods for InSb nanowire manufacturing and Mn doping both based on multi-step glancing-angle deposition process

A technology of grazing angle deposition and nanowires, which is applied in the field of nanomaterials, can solve the problems of affecting magnetic behavior, high doping of Mn elements, unfavorable InSb lattice structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments and accompanying drawings.

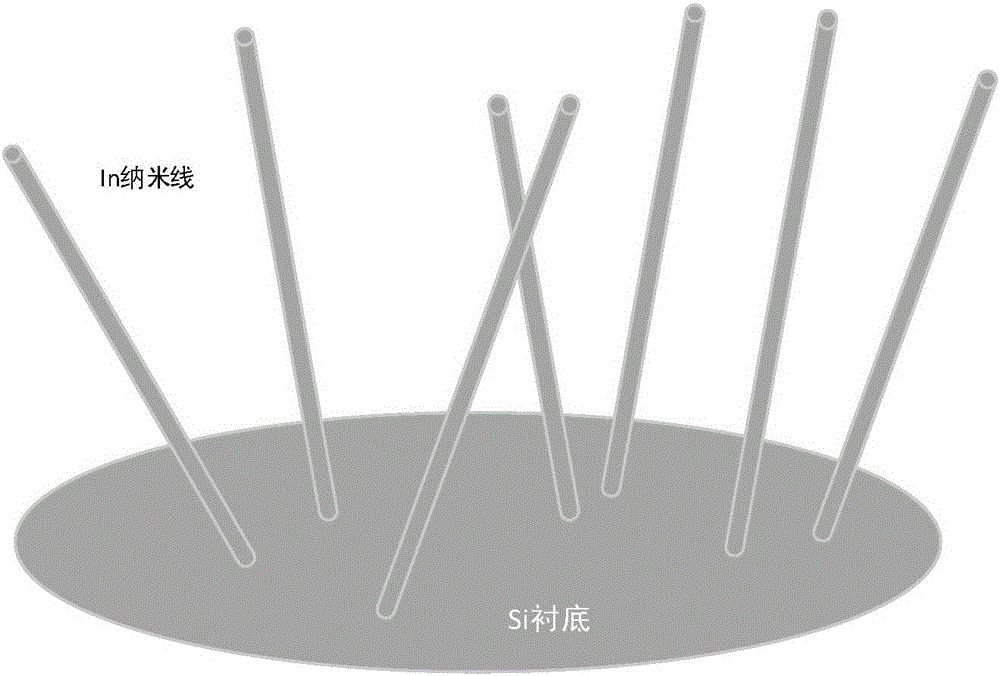

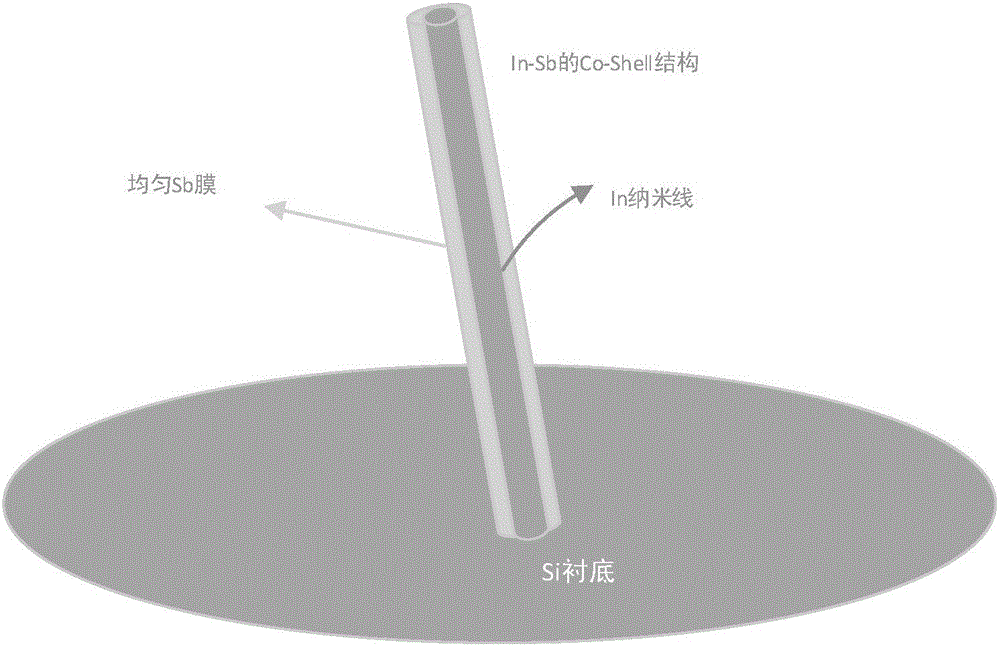

[0024] The present invention first prepares single-crystal pure In nanowires on Si / SiO2 substrates by adopting multi-step grazing angle deposition (GLAD) technology; The core-shell (core-shell) structure of Sb; finally, the core-shell structure of In and Sb is annealed at a suitable temperature to make it crystallize in the solid phase to form InSb nanowires. In this process, the present invention attempts to deposit and dope a small amount of magnetic element (Mn) between In and Sb, thereby realizing the magnetic doping of InSb nanowires.

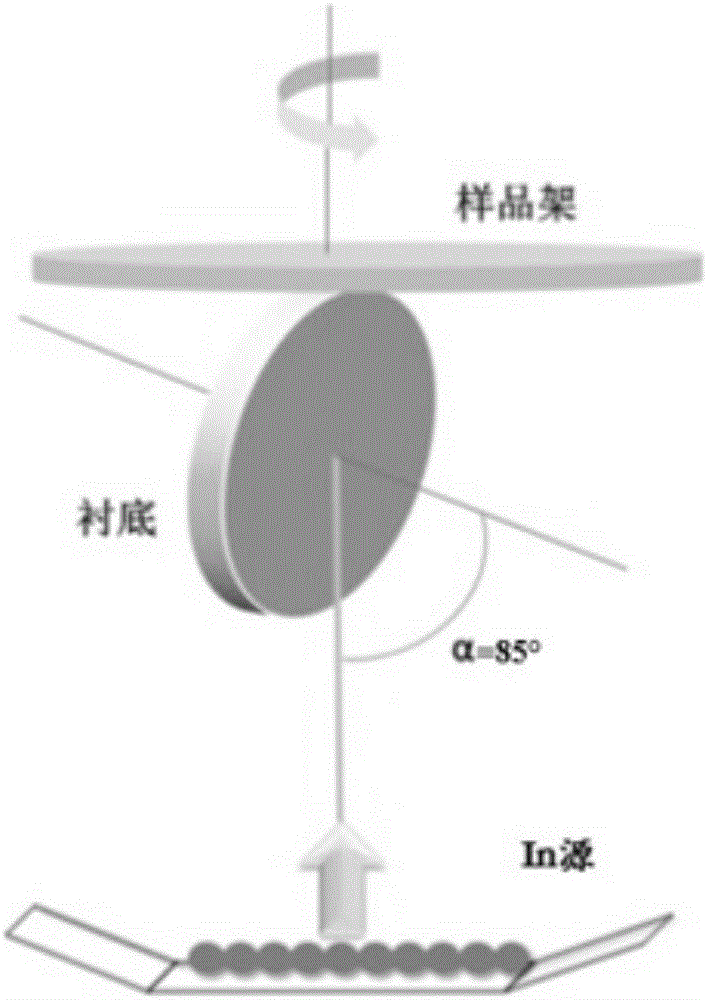

[0025] The above-mentioned InSb nanowire preparation and doping method based on the multi-step grazing angle deposition method, as shown in Figure 1 and Figure 2, specifically includes the following steps:

[0026] (1) Preparation of In nanowires

[0027] In the process of preparing pure In nanowires by the multi-step gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com