Nitrogen-oxygen-sulfur triple-doped porous carbon material and preparation method thereof

A porous carbon material and three-doping technology, which is applied in chemical instruments and methods, carbon compounds, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of high production cost of electrode materials, insufficient specific capacitance and rate performance, etc. Achieve the effects of shortening ion diffusion distance, good rate performance, and promoting intercalation/extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

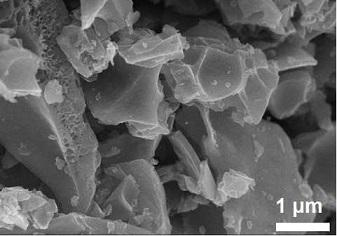

[0039] Example 1: We first washed the white fungus with distilled water and dried it. Combine dried white fungus with KNO 3 Weigh according to the mass ratio of 1:1, then KNO 3 Prepare a solution with 100 mL of distilled water, then put Tremella into it and mix, soak for 12 h, put it into a freeze dryer at -30°C for drying, and obtain dried Tremella-KNO after freeze-drying 3 Precursor mixture. After that, the mixture was placed in a tube furnace at 30 mL min -1 N 2 atmosphere with 3 o C min -1 The rate of heating up to 800 o C, and kept at this temperature for 1 h, after cooling down, the obtained product was washed with 2 M hydrochloric acid for 12 h, and then washed with distilled water for 5 times, and then the sample was placed in 80 o C dried in a vacuum oven for more than 12 h to obtain nitrogen, oxygen and sulfur triple-doped porous carbon materials. Mix the obtained carbon material with conductive carbon black (Super P) and binder (polyvinylidene fluoride) acco...

Embodiment 2

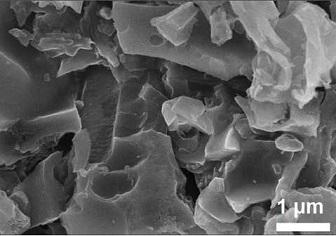

[0041] Embodiment 2: the method of this embodiment is basically the same as embodiment 1, the difference is: the carbonization activation temperature becomes 500 oC , the heating rate of the tube furnace was controlled at 0.1°C min -1 , N 2 Atmosphere flow rate is 10 mL min -1 , holding time is 10 h. The SEM picture of the electrode material is reflected in figure 2 middle. at 0 o C. 20 o C and 60 o C for supercapacitor electrodes at 100 mVs -1 The cyclic voltammetry curves at the scan rate are also reflected in Figure 6 , Figure 10 , Figure 14 middle. at 0 o C. 20 o C and 60 o C for supercapacitor electrodes at 10 A g -1 The constant current charge and discharge curve under the current density is also reflected in Figure 7 , Figure 11 , Figure 15 middle. at 0 o C. 20 o C and 60 o The change of the specific capacitance of the supercapacitor electrode under different current densities under C is also reflected in Figure 8 , Figure 12 , Figur...

Embodiment 3

[0042] Embodiment 3: the method of this embodiment is basically the same as embodiment 1, the difference is: the carbonization activation temperature becomes 900 oC , the heating rate of the tube furnace was controlled at 7°C min -1 , N 2 Atmosphere flow rate is 50 mL min -1 , holding time is 2 h. The SEM picture of the electrode material is reflected in image 3 in, at 0 o C. 20 o C and 60 o C for supercapacitor electrodes at 100 mV s -1 The cyclic voltammetry curves at the scan rate are also reflected in Figure 6 , Figure 10 , Figure 14 in, at 0 o C. 20 o C and 60 o C for supercapacitor electrodes at 10 A g -1 The constant current charge and discharge curve under the current density is also reflected in Figure 7 , Figure 11 , Figure 15 in, at 0 o C. 20 o C and 60 o The change of the specific capacitance of the supercapacitor electrode under different current densities under C is also reflected in Figure 8 , Figure 12 , Figure 16 in, at 0 o C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com