Method for enriching platinum group metal secondary resource with high efficiency

A technology for platinum group metals and secondary resources, which is applied in the field of high-efficiency enrichment of platinum group metals secondary resources, and achieves the effects of low energy consumption, good industrialization prospects and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

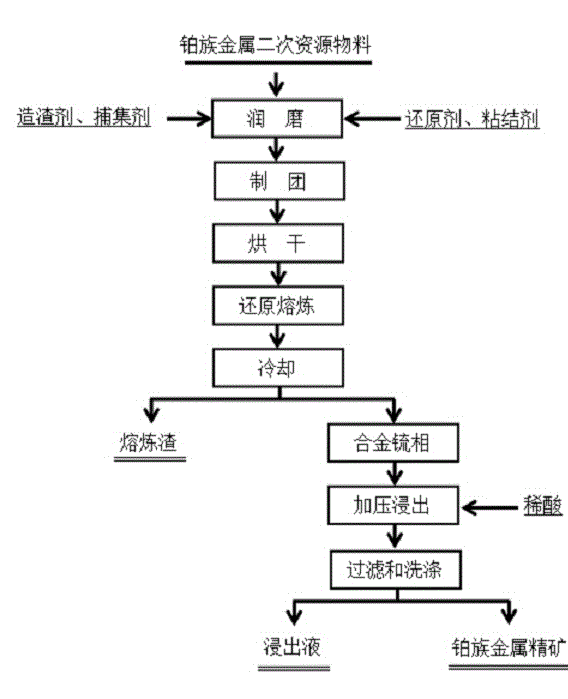

[0034] See attached figure 1 , condition: platinum group metal secondary resource material 1000g, platinum collector copper sulfide nickel ore addition is platinum group metal secondary resource material weight ratio of 30%, reducing agent anthracite addition is platinum group metal secondary resource material weight ratio 5%, the amount of binder coal tar is 0.5% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 50% of the weight ratio of platinum group metal secondary resource materials (of which lime: quartz powder: fluorescent Stone = 3:5:2), mix well, use a ball forming machine to make 5cm pellets, dry to obtain composite pellets; use graphite crucible to pack composite pellets, place them in reduction for reduction, reduction temperature 1200 °C, reduction time 2h, to obtain the platinum group metal alloy matte phase; use pressurized sulfuric acid leaching, the sulfuric acid dosage is 30% of the weight ratio of ...

Embodiment 2

[0036] See attached figure 1 , Conditions: 3000g of platinum group metal secondary resource material, the amount of platinum collector copper sulfide nickel ore is 25% by weight of the platinum group metal secondary resource material, and the reducing agent anthracite is 25% by weight of the platinum group metal secondary resource material 6%, the amount of binder coal tar is 0.4% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 40% of the weight ratio of platinum group metal secondary resource materials (of which lime: quartz powder: boron Anhydride = 4:5:1), mix well, use a ball forming machine to make 5cm pellets, dry to obtain composite pellets; use graphite crucible to pack composite pellets, place them in reduction for reduction, reduction temperature 1300 ° C, reduction time 3h, to obtain the platinum group metal alloy sulfonite phase; use pressurized sulfuric acid leaching, the sulfuric acid dosage is 40% of ...

Embodiment 3

[0038] See attached figure 1 , conditions: 2000g of platinum group metal secondary resource material, the amount of platinum collector copper sulfide nickel ore is 30% by weight of platinum group metal secondary resource material, and the amount of reducing agent anthracite is the weight ratio of platinum group metal secondary resource material 6%, the amount of binder coal tar is 0.4% of the weight ratio of platinum group metal secondary resource materials, and the amount of slagging agent is 60% of the weight ratio of platinum group metal secondary resource materials (of which lime: quartz powder: boron Anhydride: gypsum = 3:3:2:2), mix well, use a pelletizing machine to make 5cm pellets, dry to obtain composite pellets; use graphite crucible to pack composite pellets, place them in a reduction medium for reduction, and the reduction temperature is 1200 ℃, the reduction time is 3h, and the platinum group metal alloy matte phase is obtained; pressurized sulfuric acid is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com