Super-hydrophobic micro-pit array chip and preparation method and application thereof

A micro-pit array, super-hydrophobic technology, applied in biochemical equipment and methods, biochemical instruments, urinary tract/kidney cells, etc. Good compatibility, avoid cross-contamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1, preparation of superhydrophobic micropit array chip by micrografting

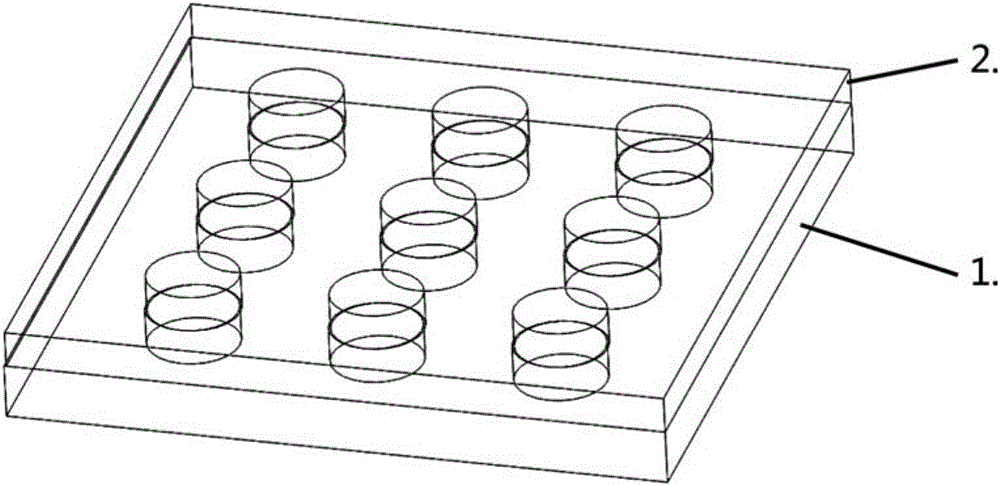

[0083] Schematic diagram of the structure of the superhydrophobic micropit array chip. figure 1 As shown, it includes a micro-pit array layer 1 and a super-hydrophobic layer 2 bonded on the surface of the micro-pit array layer, wherein the thickness of the super-hydrophobic layer 2 is 100 microns.

[0084] Such as figure 1 As shown, the superhydrophobic micropit array chip is prepared by micrografting technology, and the specific steps are as follows:

[0085] (a) Uniform glue: Taking Dow Corning 3140 as an example, a very thin layer of glue can be obtained on the PMMA layer at a speed of 7000rpm for 30s.

[0086] (b) PDMS micropit chip preparation: use the processed silicon wafer SU-8 mold (customized and processed by Boao Biochip Company), wrap it in tin foil and use it as an inverted mold container for later use. Preparation of PDMS prepolymer solution, the volume ratio of monomer an...

Embodiment 2

[0093] Example 2. Preparation of superhydrophobic micropit array chip by in situ synthesis

[0094] Schematic diagram (side view) of the structure of the superhydrophobic micropit array chip. Figure 5 As shown, it includes a base layer 1 and a superhydrophobic microporous array layer 2 attached to the surface of the substrate (the microporous array layer 2 is made of a superhydrophobic material).

[0095] Such as Image 6 As shown, the superhydrophobic micropit array chip was prepared by in situ synthesis technology, and the specific steps were as follows:

[0096] (a) Preparation of negative gel microcolumn array: uniformly 100 μm thick negative gel was applied on the silanized glass slide, exposed and developed to obtain a microcolumn array with a height of 100 μm, a diameter of 500 μm, and a center distance of 1000 μm.

[0097] (b) In-situ polymerization of the superhydrophobic layer: Align the glass slide with the micropit array with another silanized glass slide and cl...

Embodiment 3

[0099] Example 3. Superhydrophobic micropit array chip for ultra-high resolution imaging

[0100] This embodiment is based on the unique requirements of super-resolution imaging, and the preparation method of the micro-pit substrate array has been adjusted accordingly. The structure diagram of the super-hydrophobic micro-pit array chip and figure 1 Same, including the micropit array layer 1 and the superhydrophobic layer 2 bonded on the surface of the micropit array layer, only the micropit array layer 1 is composed of a base layer (special optical glass slide for ultra-high resolution imaging) and bonded on the substrate Composition of the microwell array layer on it.

[0101] Production process such as Figure 8 As shown, the specific steps are as follows:

[0102] (a) Uniform glue: Taking Dow Corning 3140 as an example, a very thin layer of glue can be obtained on the PMMA layer at a speed of 7000rpm for 30s.

[0103] (b) Preparation of photoresist dry film microarray: u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com