Fibrous composite material and preparation method thereof

A fiber composite material and composite material technology, which are applied in the field of composite materials and their preparation, can solve the problems of poor bonding between bacterial cellulose membrane and fiber membrane, cannot withstand compression, and are easy to detach and separate, so as to achieve easy industrial production, Low cost, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of bacterial cellulose: Acetobacter xylinum, a microorganism of the genus Acetobacter, which can secrete bacterial cellulose, is activated to prepare seed wake-up liquid, and then the seed wake-up liquid is added to the sterilized fermentation medium, and heated at 30°C Cultivate in the incubator for 7 days to make the bacteria multiply and grow to a certain concentration.

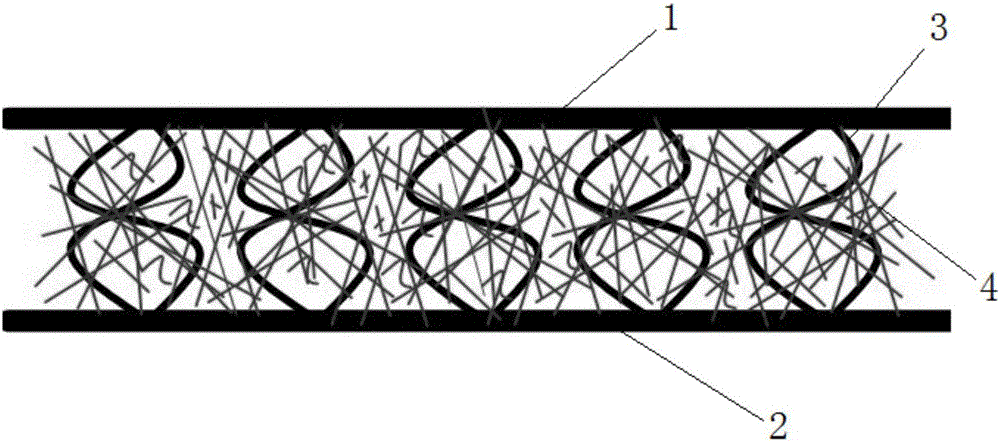

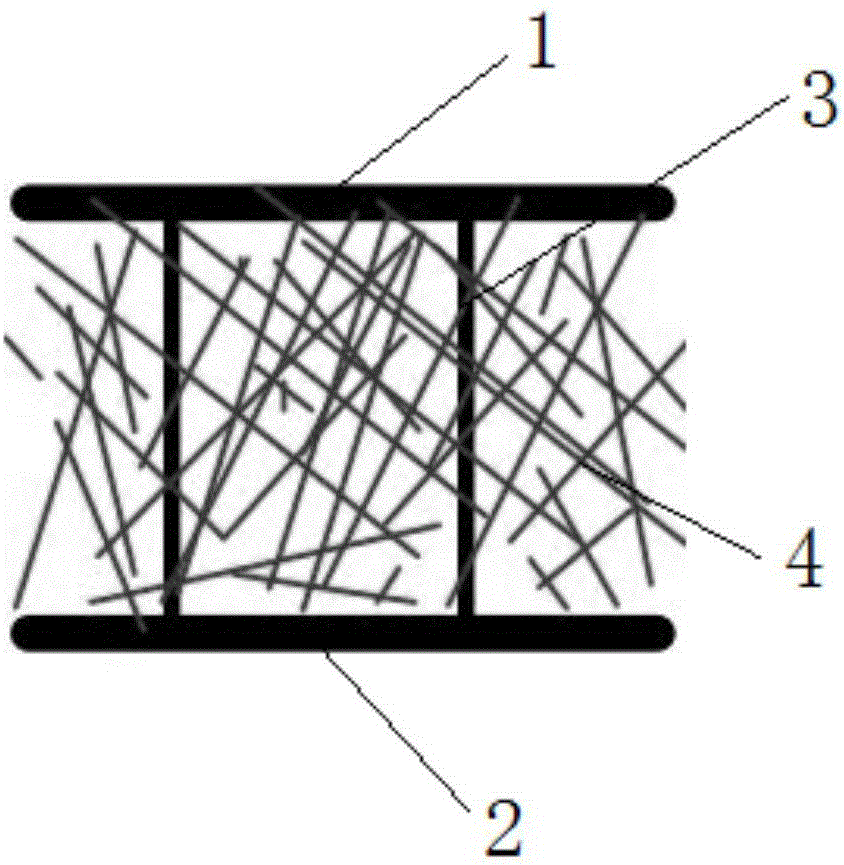

[0030] (2) Combination of fabric and bacterial cellulose: In this example, polyester warp-knitted spacer fabric with a thickness of 3 mm is used, and the upper and lower surfaces of the fabric are mesh structures. Cut the fabric into a circle with a diameter of about 7cm, and place it in a petri dish. Then the culture solution of the above-mentioned bacterial cellulose is poured into the petri dish, and the height of the liquid level is controlled below 3 mm. Then seal it with a parafilm, and culture it in an incubator at 30° C. for 4 days. Bacterial cellulose grows disorderly in t...

Embodiment 2

[0033] (1) Preparation of bacterial cellulose: Acetobacter xylinum, a microorganism of the genus Acetobacter, which can secrete bacterial cellulose, is activated to prepare seed wake-up liquid, and then the seed wake-up liquid is added to the sterilized fermentation medium, and the biological fermentation tank is used to A large amount of production is carried out to make the bacteria multiply and grow to a certain concentration.

[0034] (2) In-situ compounding of fabric and bacterial cellulose: In this example, polyester warp-knitted spacer fabric with a thickness of 6 mm is used, and the upper and lower surfaces of the fabric are of mesh structure. Pour the bacterial cellulose culture solution into it, control the liquid level below 6mm, and cultivate it in an incubator at 37°C for 7 days. Bacterial cellulose grows disorderly in the voids of the warp-knitted spacer fabric, forming an in-situ nanocomposite. Bacterial cellulose grows in the middle layer of the fabric, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com