Preparation method for fluorine-doping Li4Ti5O12 nanosheet

A lithium titanate, fluorine doping technology, applied in titanate, nanotechnology, nanotechnology and other directions, can solve the problems of rapid capacity decay and poor performance, and achieve improved electrochemical performance, uniform morphology and good crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 0.168 g of lithium hydroxide monohydrate, 1.7 g of tetrabutyl titanate, 0.015 g of lithium fluoride, and 20 mL of absolute ethanol in a 100 mL three-necked flask, stir for 12 hours in a dry environment, and then add 25 mL of deionized After the water was vigorously stirred for 0.5 h, the milky white solution was placed in a 50 mL polytetrafluoroethylene stainless steel reactor for hydrothermal reaction at 180 °C for 36 h. The white powder deposited in the reactor was taken out, washed with absolute ethanol three times, centrifuged, and dried in an oven at 60 °C for 8 h to obtain the precursor of fluorine-doped lithium titanate nanosheets. The precursor was placed in a tube furnace and calcined at 600 °C for 6 h under the protection of argon atmosphere to obtain fluorine-doped lithium titanate nanosheets.

Embodiment 2

[0022] Take 0.189 g of lithium hydroxide monohydrate, 1.7 g of tetrabutyl titanate, 0.010 g of lithium fluoride, and 20 mL of absolute ethanol in a 100 mL three-necked flask, stir for 12 hours in a dry environment, and then add 25 mL to After the deionized water was vigorously stirred for 0.5 h, the milky white solution was placed in a 50 mL polytetrafluoroethylene stainless steel reactor for hydrothermal reaction at 160 °C for 20 h. The white powder deposited in the reactor was taken out, washed with absolute ethanol three times, centrifuged, and dried in an oven at 60 °C for 8 h to obtain the precursor of fluorine-doped lithium titanate nanosheets. The precursor was placed in a tube furnace and calcined at 800 °C for 5 h under the protection of argon atmosphere to obtain fluorine-doped lithium titanate nanosheets.

Embodiment 3

[0024]Take 0.204 g of lithium hydroxide monohydrate, 1.7 g of tetrabutyl titanate, 0.005 g of lithium fluoride, and 20 mL of absolute ethanol in a 100 mL three-necked flask, stir for 12 hours in a dry environment, and then add 25 mL to After the ionic water was vigorously stirred for 0.5 h, the milky white solution was placed in a 50 mL polytetrafluoroethylene stainless steel reactor for hydrothermal reaction at 200 °C for 24 h. The white powder deposited in the reactor was taken out, washed with absolute ethanol three times, centrifuged, and dried in an oven at 60° C. for 8 hours to obtain a fluorine-doped lithium titanate nanosheet precursor. The precursor was placed in a tube furnace and calcined at 700 °C for 4 h under the protection of argon atmosphere to obtain fluorine-doped lithium titanate nanosheets.

[0025] 2. Verification effect:

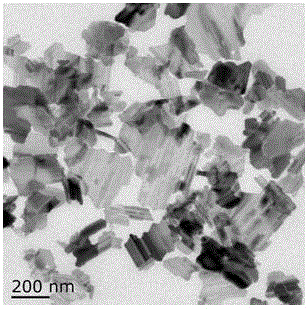

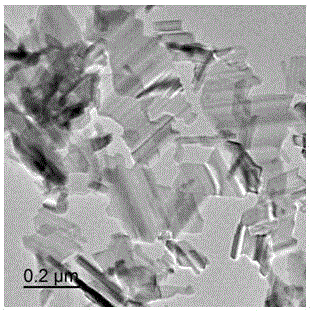

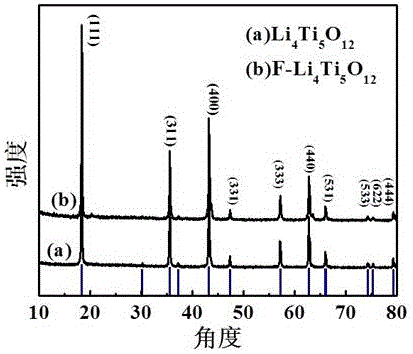

[0026] figure 1 It is the transmission electron microscope picture of the pure lithium titanate nanosheet synthesized by the above e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com