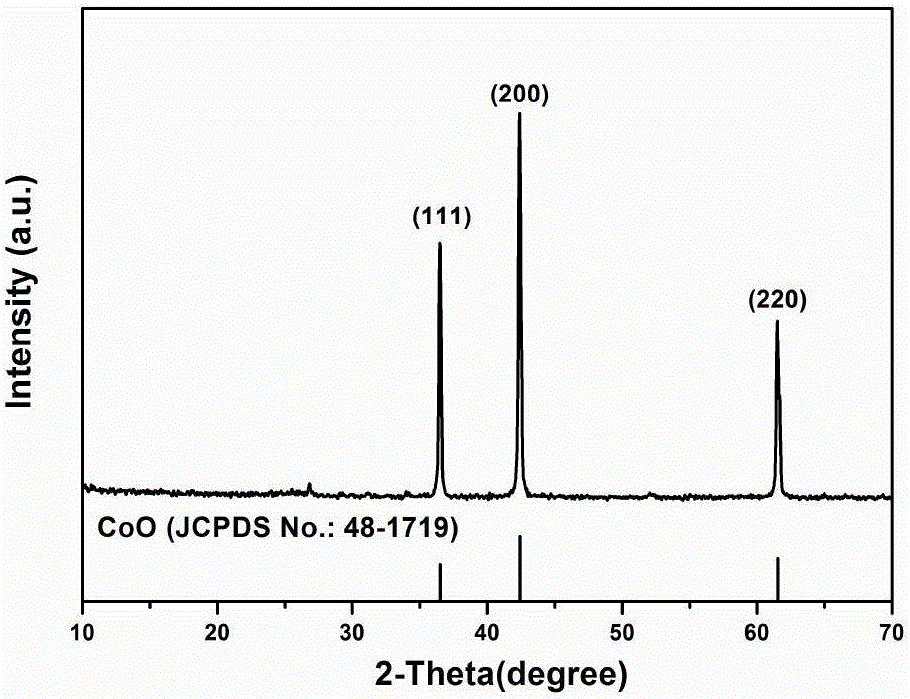

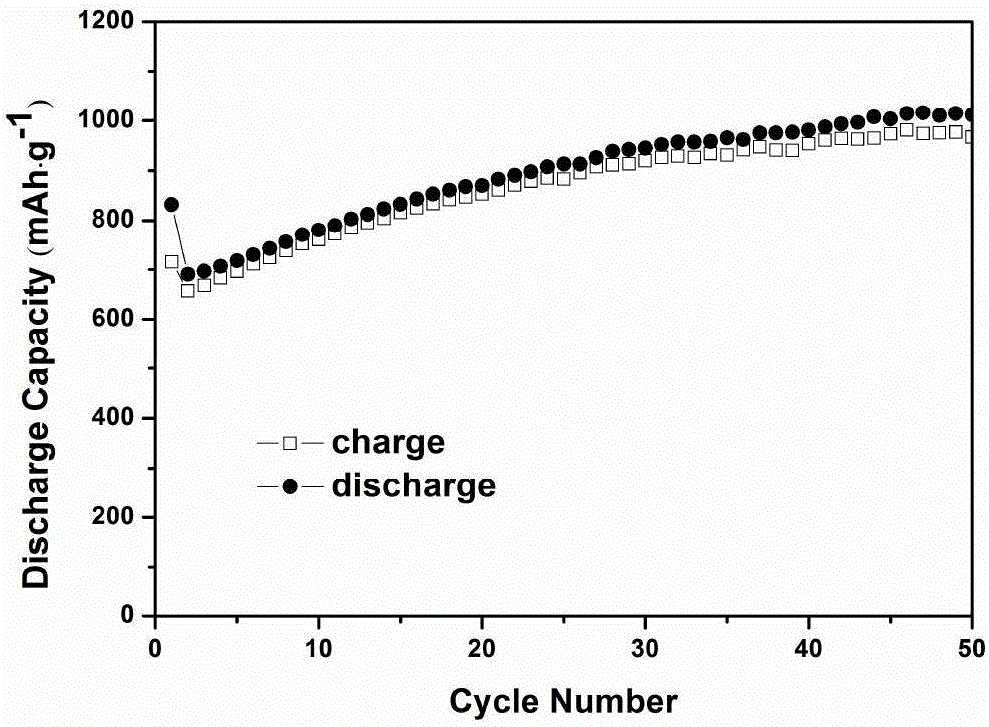

Method for preparing anode material of three-dimensional porous carbon skeleton/CoO composite structured lithium ion battery

A lithium-ion battery, composite structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of small specific surface area of materials and less loaded oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: A preparation method of a three-dimensional porous carbon skeleton / CoO composite structure lithium-ion battery negative electrode material,

[0020] 1) Wash the peanut skins and dry them;

[0021] 2) Put 3 g of peanut skins into 60 ml of concentrated sulfuric acid solution with a concentration of 5 mol / L, and react in an oven at 80°C for 5 hours to obtain suspension A;

[0022] 3) Suspension A was subjected to vacuum filtration, and rinsed with deionized water to pH = 7, then collected and dried to obtain precursor B;

[0023] 4) Mix precursor B and potassium hydroxide at a mass ratio of 1:1 and grind them evenly to obtain product C;

[0024] 5) Put the product C into a tube furnace with argon gas, set the reaction temperature to 800°C, keep it warm for 2h, and the heating rate is 3°C·min -1 , argon flow rate 0.2sccm·min -1 , to obtain the product D;

[0025] 6) Add 0.02mol of analytically pure cobalt acetate tetrahydrate and 0.06mol of urea into 100ml of...

Embodiment 2

[0029] Example 2: A preparation method of a three-dimensional porous carbon skeleton / CoO composite structure lithium ion battery negative electrode material,

[0030] 1) Wash the garlic skin and dry it;

[0031] 2) Put 4 g of garlic skin into 60 ml of concentrated sulfuric acid solution with a concentration of 7 mol / L, and react in an oven at 80°C for 7 hours to obtain suspension A;

[0032] 3) Suspension A was subjected to vacuum filtration, and rinsed with deionized water to pH = 7, then collected and dried to obtain precursor B;

[0033]4) Mix precursor B and potassium hydroxide at a mass ratio of 1:2 and grind them evenly to obtain product C;

[0034] 5) Put the product C into a tube furnace with argon gas, set the reaction temperature to 700°C, keep it warm for 3h, and the heating rate is 5°C·min -1 , argon flow rate 0.5sccm·min -1 , to obtain the product D;

[0035] 6) Take 0.02mol of analytically pure cobalt acetate tetrahydrate and 0.08mol of urea into 100ml of dei...

Embodiment 3

[0037] Example 3: A preparation method of a three-dimensional porous carbon skeleton / CoO composite structure lithium-ion battery negative electrode material,

[0038] 1) Wash the onion skin and dry it;

[0039] 2) Put 6g of green onion skin into 60ml of concentrated sulfuric acid solution with a concentration of 10mol / L, and react in an oven at 80°C for 6h to obtain suspension A;

[0040] 3) Suspension A was subjected to vacuum filtration, and rinsed with deionized water to pH = 7, then collected and dried to obtain precursor B;

[0041] 4) Mix precursor B and potassium hydroxide at a mass ratio of 1:3 and grind them evenly to obtain product C;

[0042] 5) Put the product C into a tube furnace with argon gas, set the reaction temperature to 900°C, keep it warm for 1h, and the heating rate is 8°C·min -1 , argon flow rate 0.4sccm·min -1 , to obtain the product D;

[0043] 6) Add 0.02mol of analytically pure cobalt acetate tetrahydrate and 0.07mol of urea into 100ml of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com