Preparation method for surface-enhanced Raman substrate and surface-enhanced Raman substrate structure

A surface-enhanced Raman and substrate structure technology, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of small substrate area, large area of contaminated substrate, difficulty in ensuring consistency, and high preparation cost. Achieve high sensitivity, simple and convenient preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

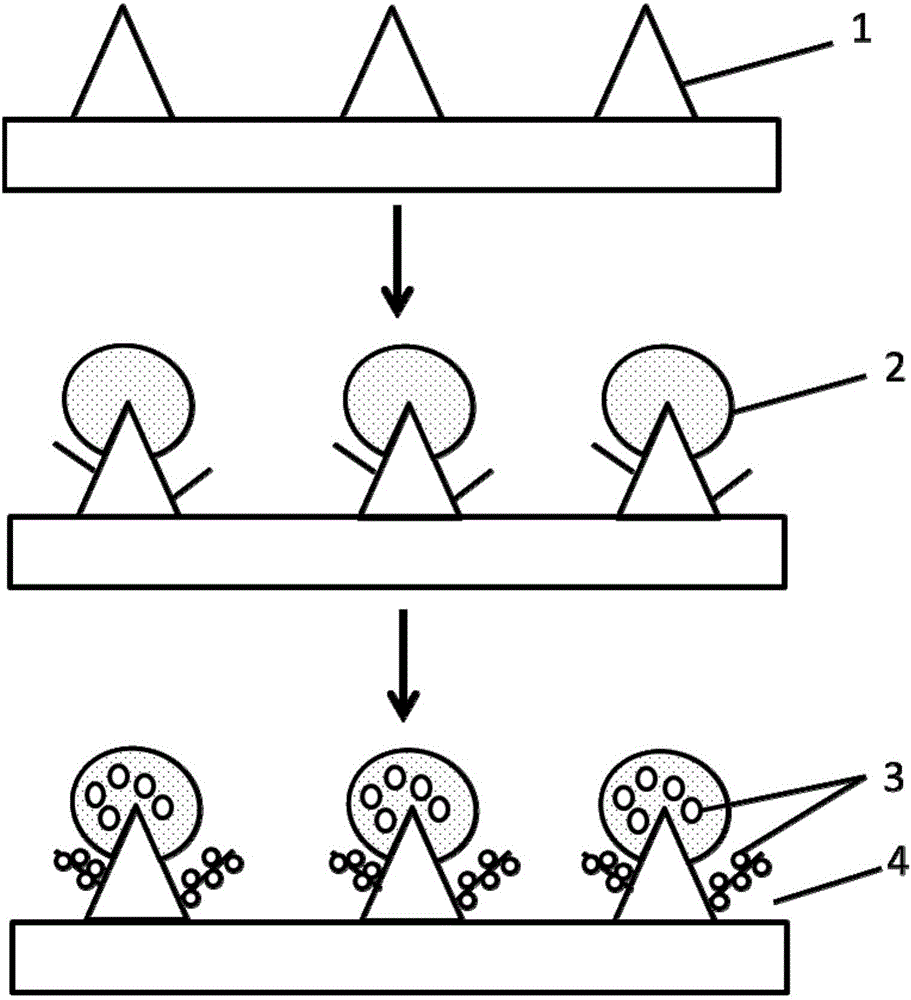

[0032] figure 1 It is a process flow diagram of a method for preparing a surface-enhanced Raman substrate 4 according to an embodiment of the present invention. see figure 1 , the present invention provides a method for preparing a surface-enhanced Raman substrate 4, forming a composite structure with surface-enhanced Raman characteristics through graphene nanosheets 2 and metal particles 3, comprising the following steps:

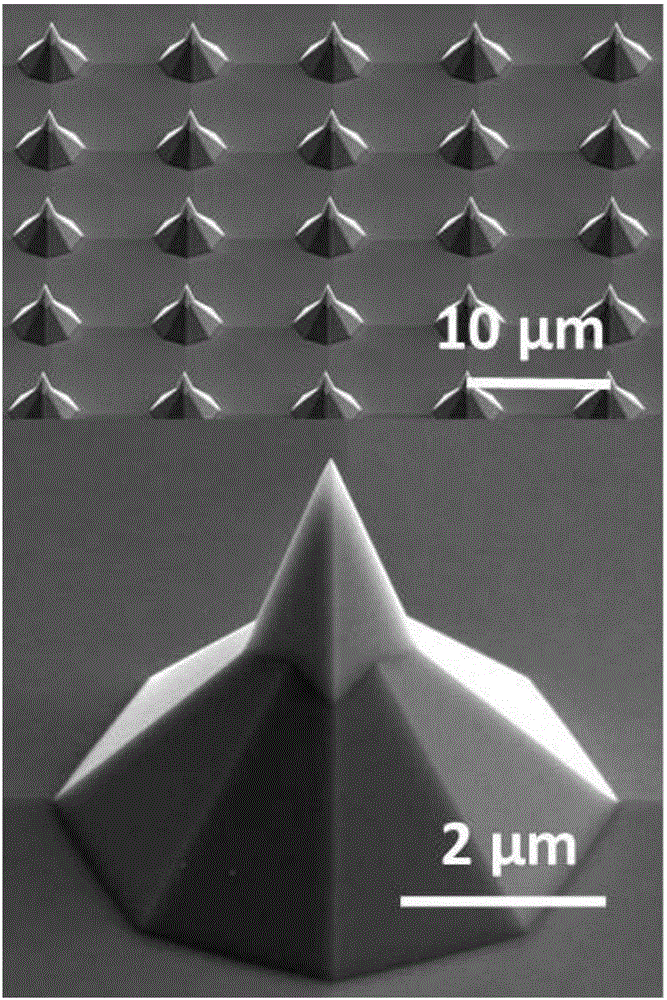

[0033] Step 1. Select a silicon substrate and etch the silicon substrate to prepare a silicon pyramid array 1 . Such as Figure 2a SEM side view of the sample after step 1 is shown.

[0034] Step 2, putting the silicon pyramid array 1 into a microwave plasma chemical vapor deposition system to grow graphene nanosheets 2 . Such as Figure 2b SEM side view of the sample after step 2 is shown.

[0035] Step 3, coating a layer of metal particles 3 on the surface of the graphene nanosheet 2, so that the surface-enhanced Raman substrate 4 can be obtained. ...

Embodiment 1

[0049] see figure 1, select a silicon (100) substrate, where 100 is the crystal plane of silicon, deposit a 60nm thick silicon nitride film on the silicon (100) substrate, and perform photolithography, etching, and wet etching on the silicon nitride film To prepare the silicon pyramid array 1; put the silicon pyramid array 1 into the microwave plasma chemical vapor deposition (MPCVD) system, the basic vacuum is 0.1Pa, the gas flow ratio of methane and hydrogen is 2:1, and the air pressure is 600Pa keep it for 3min, and grow graphene nanosheets 2; use DC magnetron sputtering to deposit a Ag film with a thickness of 3nm on the graphene nanosheets 2, the basic vacuum is 5E-9Torr, the speed of the sample stage is 10rpm, and the sputtering power It is 100W, and the working air pressure is 0.004Torr.

[0050] Figure 3a It is a scanning electron microscope side view of the front of one of the graphene nanosheets 2 of the surface-enhanced Raman substrate 4 prepared in Example 1 of ...

Embodiment 2

[0052] see figure 1 , select a silicon (100) substrate, where 100 is the crystal plane of silicon, deposit a 60nm thick silicon nitride film on the silicon (100) substrate, and perform photolithography, etching, and wet etching on the silicon nitride film To prepare the silicon pyramid array 1; put the silicon pyramid array 1 into a microwave plasma chemical vapor deposition (MPCVD) system, the basic vacuum is 0.1Pa, the gas flow ratio of methane and hydrogen is 3:1, and the air pressure is 600Pa keep it for 3min, grow graphene nanosheets 2; use DC magnetron sputtering to deposit a Ag film with a thickness of 5nm on the graphene nanosheets 2, the basic vacuum is 5E-9Torr, the sample stage speed is 10rpm, and the sputtering power It is 100W, and the working air pressure is 0.004Torr.

[0053] Figure 4a It is a scanning electron microscope side view of the front of one of the graphene nanosheets 2 of the surface-enhanced Raman substrate 4 prepared in Example 2 of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com