Methane recovery system and recovery method

A recovery system, methane technology, applied in the field of recovery of boil-off gas (BOG), can solve the problem of low recovery efficiency and achieve the effect of achieving safety and recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

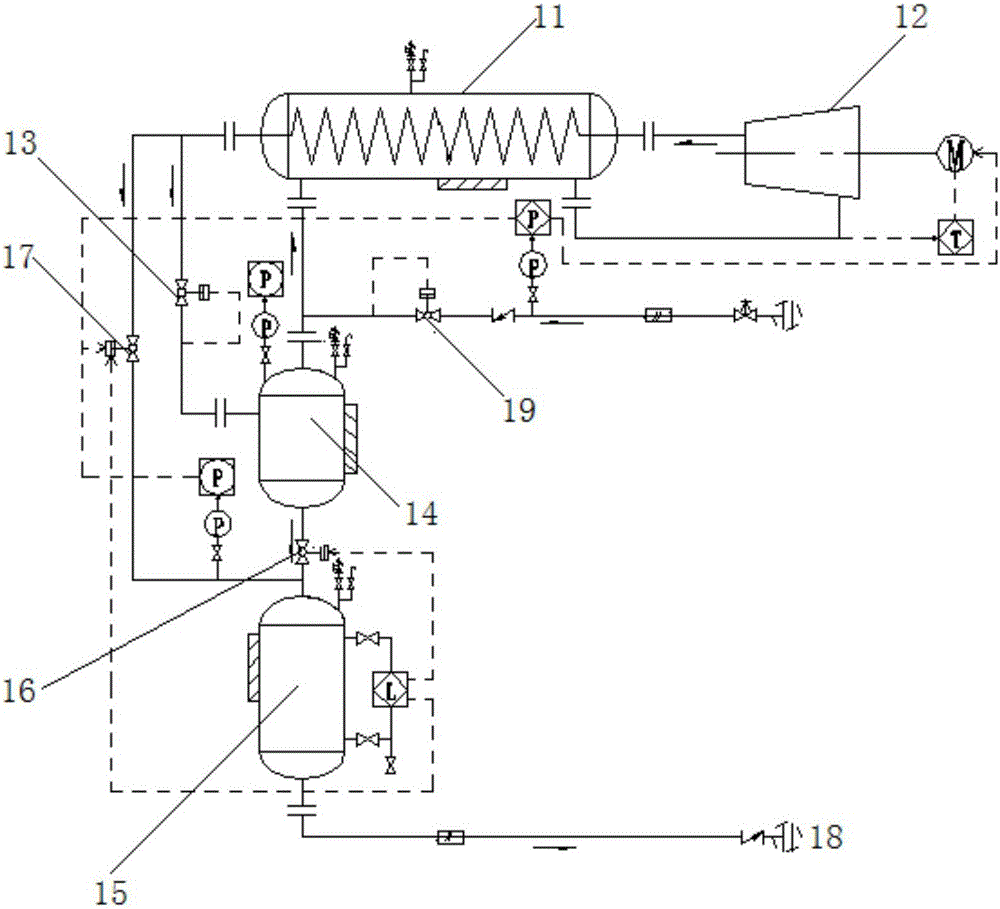

Embodiment 1

[0024] like figure 1 As shown, this embodiment provides a methane recovery system, the system includes a heat exchange device 11 for receiving methane gas, and the heat exchange device 11 includes at least two channels, wherein the inlet of the first channel is connected to the gas-liquid separation device 14, the outlet of the first passage is connected with the inlet of the compression device 12, the inlet of the second passage is connected with the outlet of the compression device 12, and the outlet of the second passage is connected with the gas outlet through the throttling and stabilizing device 13. The inlet of the liquid separation device 14 is connected, the liquid outlet of the gas-liquid separation device 14 is connected with the inlet of the liquid storage tank 15, and the liquid outlet of the gas-liquid separation device 14 is connected to the inlet of the liquid storage tank 15. A cut-off valve 16, the liquid storage tank 15 is provided with a booster port, the b...

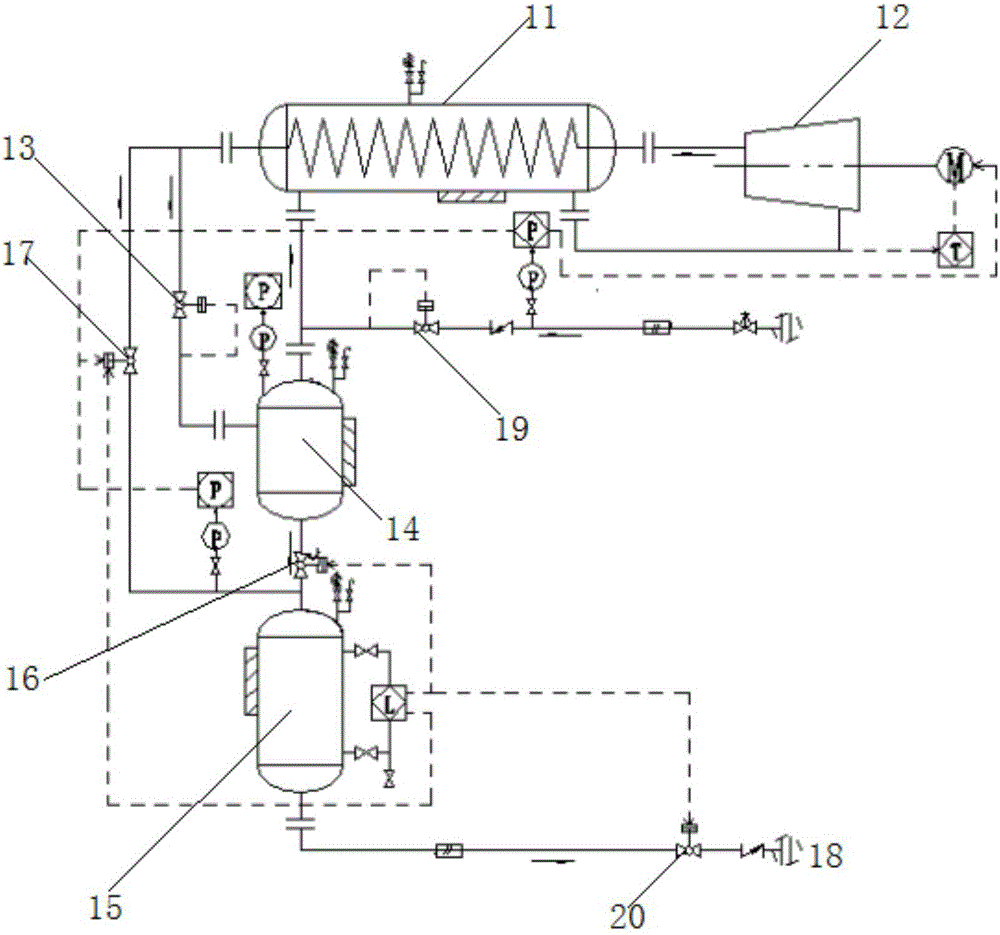

Embodiment 2

[0032] Embodiment 2 is an improvement made on the basis of Embodiment 1. In order to improve the system for recovering methane gas, the methane liquid discharged from the liquid storage tank 15 is improved on the system of Embodiment 1. The following details:

[0033] like figure 2 As shown, in order to better control the discharge of the methane liquid, the outlet of the liquid storage tank 15 is connected to the liquid inlet of the methane storage tank 18 through a liquid discharge valve 20, and the liquid level of the liquid storage tank 15 reaches a predetermined When within the range, close the cut-off valve 16, stop methane liquid from flowing into the liquid storage tank 15 from the gas-liquid separation device 14, then open the liquid discharge valve 20, and finally gradually open the booster valve 17, through The pressure boost valve 17 adjusts the pressure of the liquid storage tank 15, thereby facilitating liquid discharge; when the liquid level of the liquid stora...

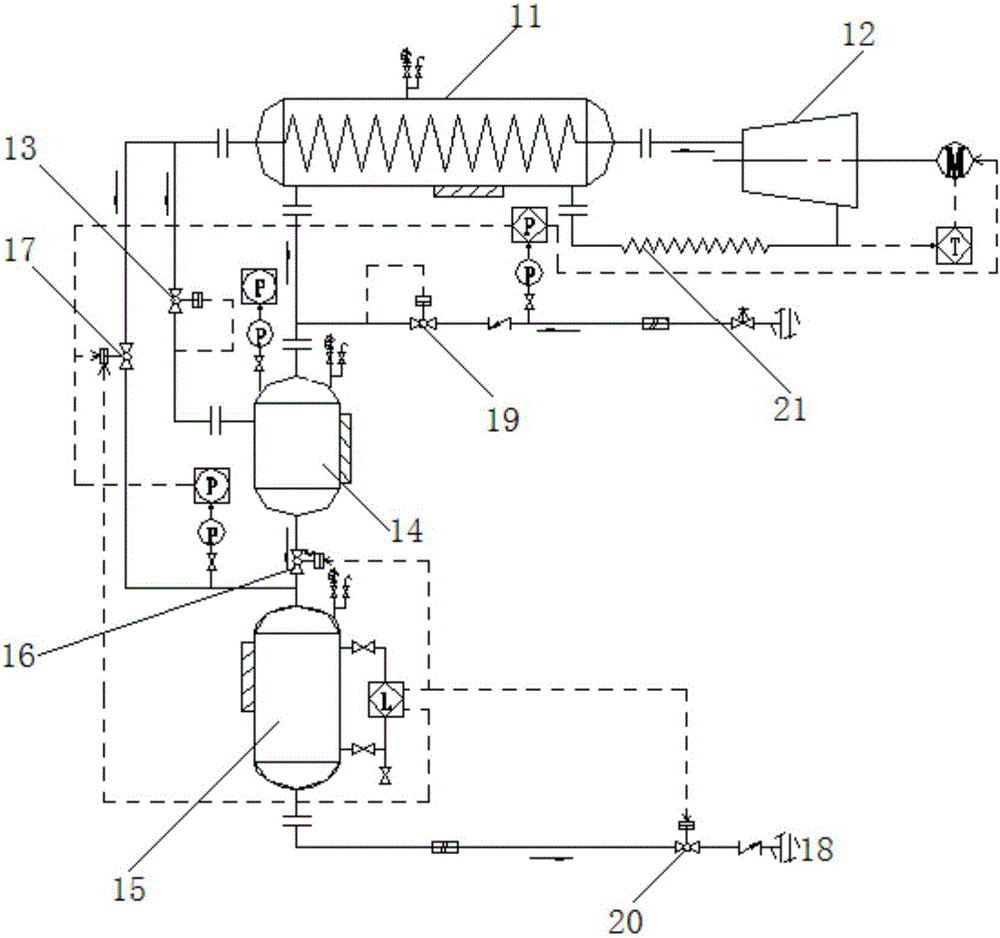

Embodiment 3

[0035] Embodiment 3 is an improvement made on the basis of Embodiment 1 or Embodiment 2. In order to meet the requirements for the gas to enter the compression device, the system of Embodiment 1 or Embodiment 2 controls the gas before entering the compression device. Improvements are made in detail below:

[0036] like image 3 As shown, in order to ensure that the outlet gas of the first passage of the heat exchange device 11 meets the requirements of the inlet of the compression device 12, the outlet of the first passage of the heat exchange device 11 passes through the heater 21 and the inlet of the compression device 12 connected, the heater 21 is used to heat the methane gas discharged from the first channel of the heat exchange device 11 to increase the temperature of the gas, thereby helping to meet the temperature requirements of the compression device 12 for the inlet gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com