Nanosheet-layer tungsten disulfide reinforced carbon fiber sizing agent and preparation method thereof

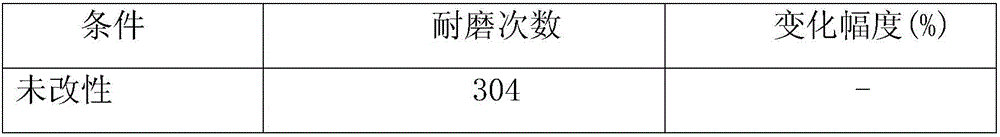

A technology of tungsten disulfide and nanosheets, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., to achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

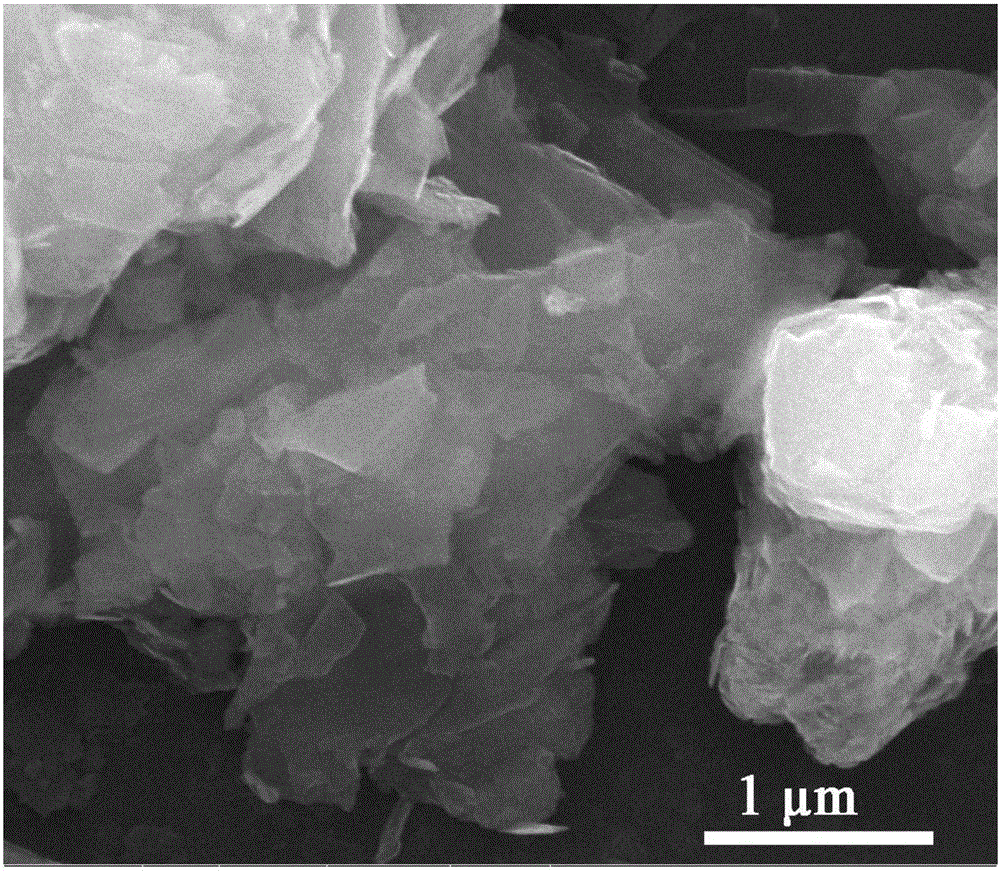

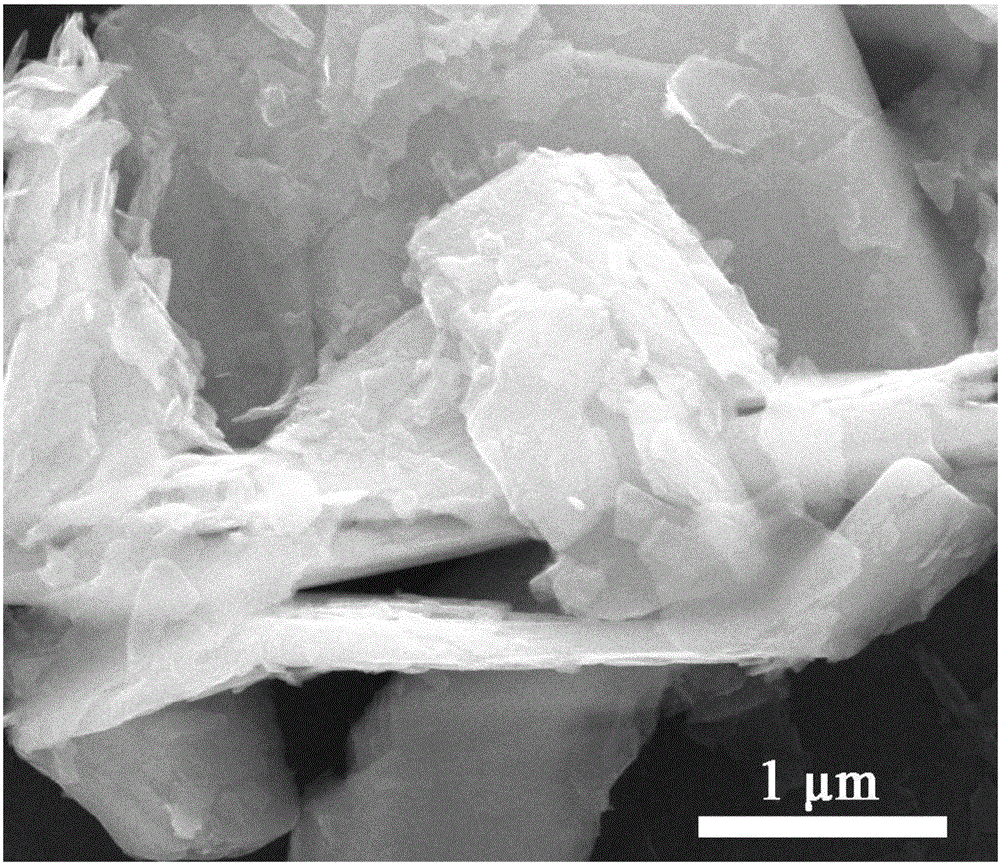

[0033] The compatible modified nanosheet tungsten disulfide described in the present invention refers to the modified nanosheet formed by grafting polyacrylic acid in situ on the surface of the stripped nanosheet tungsten disulfide by an ammonium persulfate initiator Tungsten disulfide is added in the form of dispersion liquid in the sizing agent, and the dispersion liquid preparation method comprises the following steps:

[0034] 1) Prepare a mixed solution of isopropanol and water first, wherein the volume percentage of isopropanol in the mixed solution is 30%-70%, and then add tungsten disulfide with a size less than 100 microns to form a tungsten disulfide concentration of 10mg / mL dispersion;

[0035] 2) Ultrasonic the dispersion liquid obtained in step 1), after standing still, centrifuge to obtain the upper layer dispersion liquid;

[0036] 3) The dispersion obtained in step 2) is subjected to polyacrylic acid modification treatment: acrylic acid and ammonium persulfate...

Embodiment 1

[0046] Step (1): At 70°C, disperse 1000 grams of epoxy resin (brand 634) in 1500 grams of N-methylpyrrolidone to form an organic resin solution;

[0047] Step (2): After the resin solution is down to room temperature, mix 10 grams of surfactant Solulan 25, 5 grams of polyethylene glycol 1000 and 500 grams of deionized water into the organic resin solution, and use a dispersing emulsifier to shear to Phase transfer occurs in the mixing system, and the rotation speed of the dispersing emulsifier is 19000 rpm; after continuing to shear for 60 minutes, add deionized water until the solid content of the mixing system is 35%, and an organic resin emulsion is obtained;

[0048] Step (3): Slowly add 6 grams of the compatible modified nanosheet tungsten disulfide dispersion into the organic resin emulsion, and disperse it ultrasonically for 1 hour with a power of 600W, then continue to add deionized water, and dilute the mixed system to a solid content of 30% to prepare a compatible mo...

Embodiment 2

[0050] Step (1): at 70 DEG C, 1000 grams of epoxy resin (brand 618) is dispersed in 1200 grams of acetone to form an organic resin solution;

[0051] Step (2): After the resin solution drops to room temperature, mix 10 grams of Solulan97, 6 grams of KH570 and 500 grams of deionized water and add them into the organic resin solution, and use a dispersing emulsifier to shear until the mixed system undergoes phase transfer and disperse The rotation speed of the emulsifier is 17000rpm; after continuing to shear for 60 minutes, add deionized water until the solid content of the mixed system is 35%, and an organic resin emulsion is obtained;

[0052] Step (3): Slowly add 8 grams of the compatible modified nanosheet tungsten disulfide dispersion into the organic resin emulsion, and disperse it ultrasonically for 1 hour with a power of 500W, then continue to add deionized water, and dilute the mixed system to a solid content of 28%, to prepare compatible modified nanosheet tungsten di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com