Tower type multi-stage electrostatic zero-damage foreign fiber separating device

A technology of foreign fiber and separation device, which is applied in the field of agricultural machinery, can solve the problems of low separation efficiency, short charging time, and affecting the quality grade of cotton, and achieve the effect of high separation efficiency and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

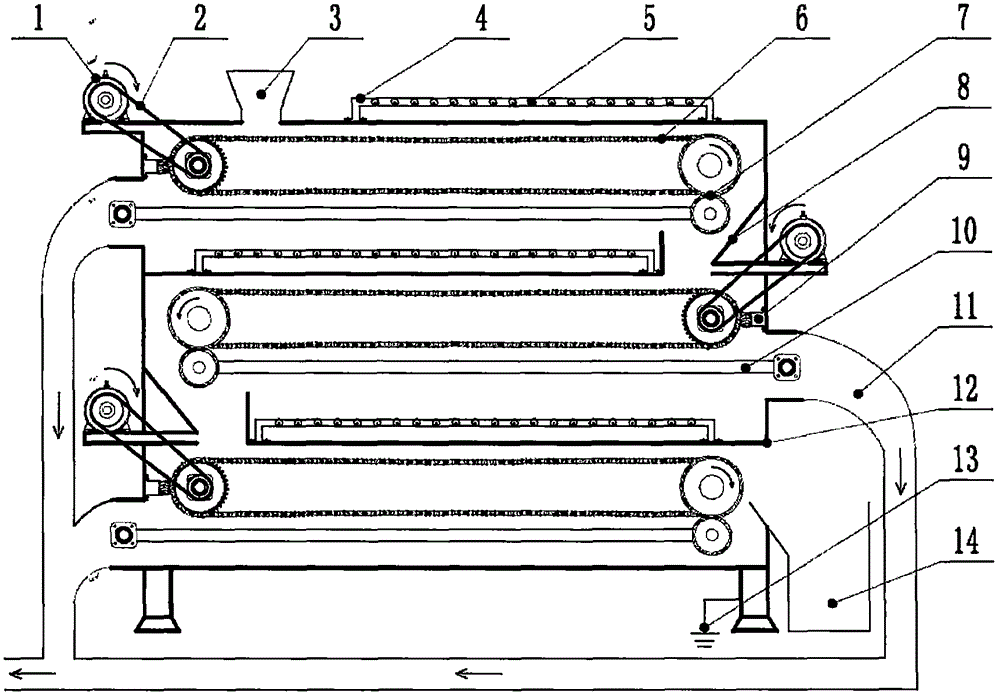

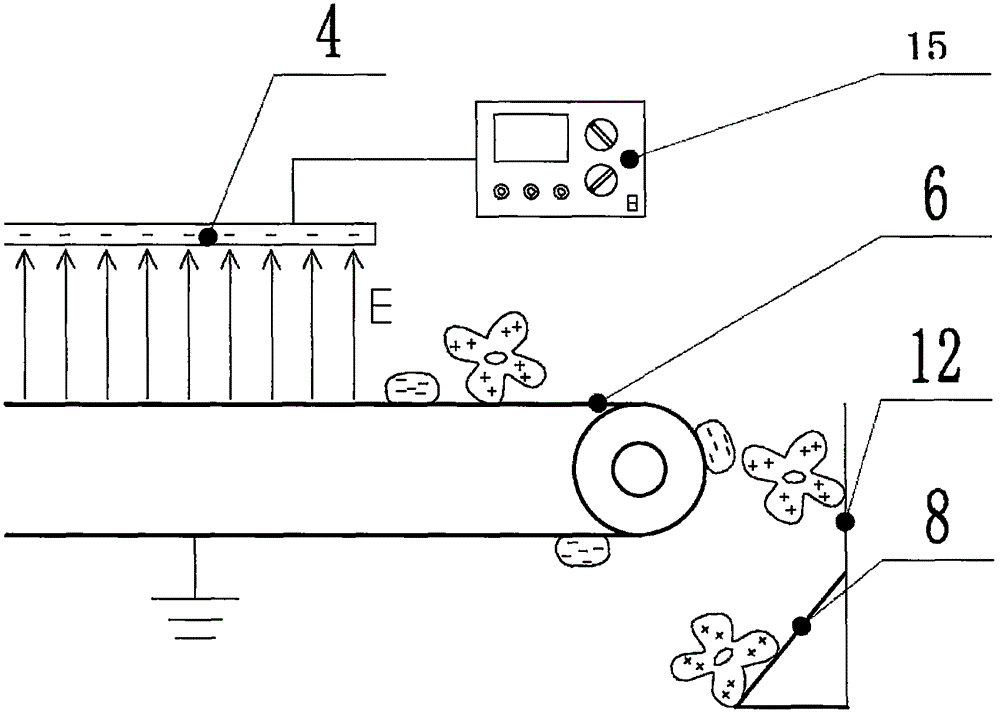

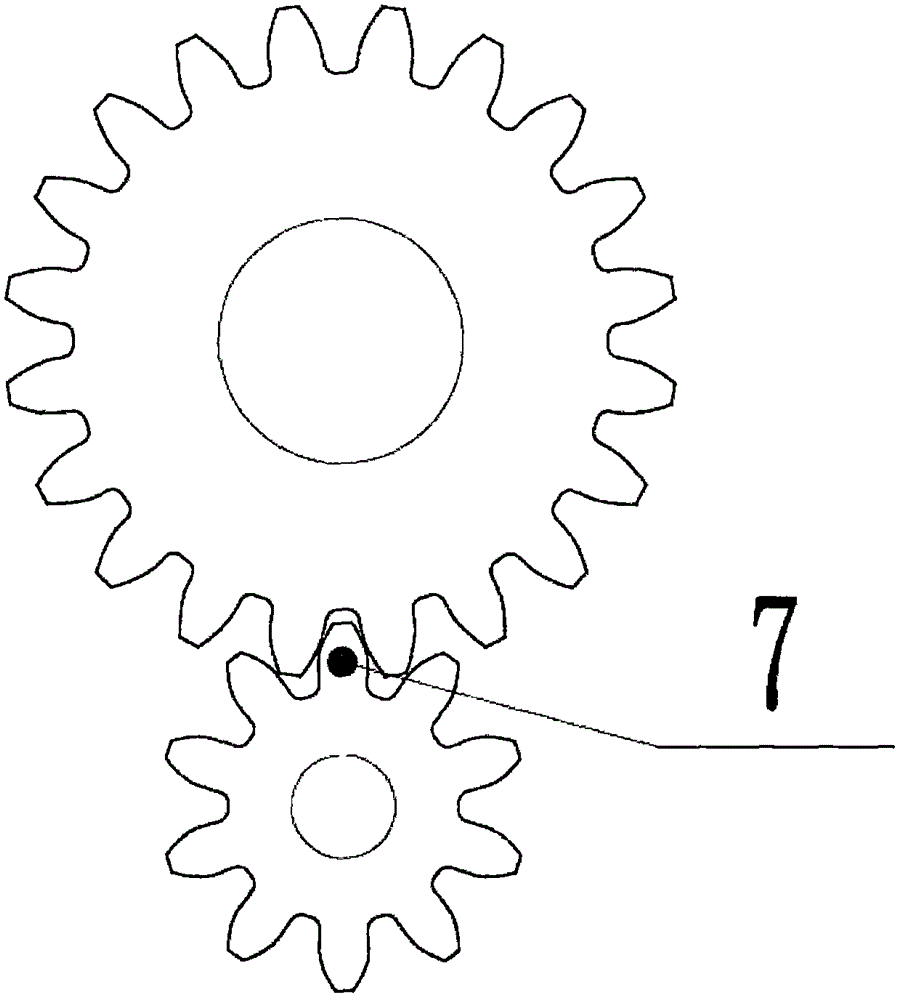

[0014] Embodiment: refer to attached figure 1 , present embodiment: comprise frame (12), motor (1), feeding port (3), conveyor mesh belt (6), transmission gear (7), electrode plate (4), serrated electrode (5), Seed cotton slide (8), brush (9), foreign fiber conveyor belt (10), foreign matter negative pressure output pipe (11), high-voltage electrostatic generator (15), and electrode plates (4 ), fixed to the frame (12) by bolt connection. The conveying mesh belt (6) and the foreign fiber conveying belt (10) are respectively fixed to the frame (12) through bearing seats. The power of the conveyor belt (6) is provided by the motor (1), and the heterosexual fiber conveyor belt (10) is driven by the transmission gear (7). The brush (9) is fixed above the inlet of the foreign matter negative pressure output pipeline (11) and is in contact with the conveying mesh belt (6). The high-voltage electrostatic generator (14) is connected with the serrated electrode (5) in the electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com