High-temperature alloy oxidation-resistance and corrosion-resistant protective coating

A technology of protective coating and superalloy, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve blank and other problems, and achieve the effect of convenient operation, easy realization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

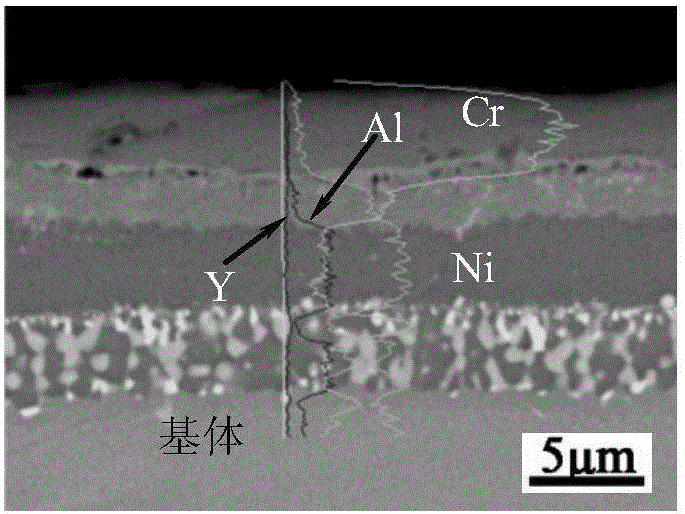

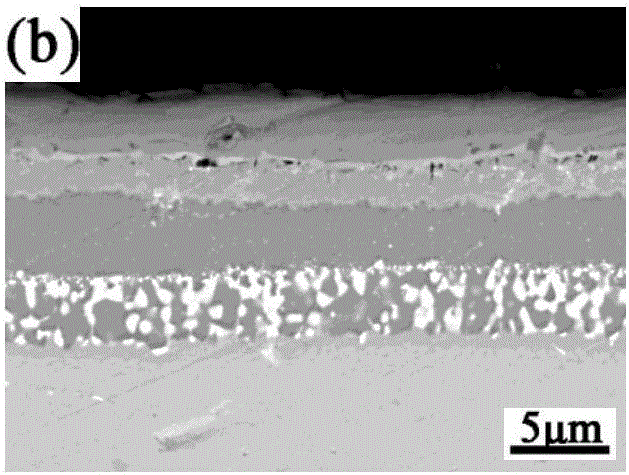

Embodiment 1

[0048] ①Surface pretreatment: remove oxide scales and adherents on the surface of the nickel-based alloy sample or workpiece to keep the surface of the sample clean; Soak for 15 minutes; ③Water washing: Rinse the sample or workpiece after alkali washing with running water, and then dry it for use; ④Preparation of protective coating: Weigh it accurately according to the amount, and the proportion of the protective coating is as follows: 5% Cr powder, 10% Al powder, 6% NH4Cl (analytical pure), 1% Y2O3 powder, the rest is Al 2 o 3 powder (≤250 mesh); ⑤Ball milling: Put the prepared protective coating in a ball mill and grind it for 1-3 hours to make the composition uniform and to refine the grains, and the particles of the penetrating agent should be refined to no more than 200 mesh; ⑥Drying: Put the ball-milled protective coating in an oven at 100°C for 1 hour and then dry it; ⑦Embedding: Put the dried protective coating into a corundum crucible, and place the The samples or w...

Embodiment 2

[0050] ①Surface pretreatment: remove oxide scales and adherents on the surface of nickel-based alloy samples or workpieces to keep the surface of the samples clean; Soak for 12 minutes; ③Water washing: Rinse the sample or workpiece after alkali washing with running water, and then dry it for use; ④Preparation of protective coating: Weigh it accurately according to the amount, and the proportion of the protective coating is as follows: 8% Cr powder, 15% Al powder, 8% NH4Cl (analytical pure), 1.5% Y2O3 powder, the rest is Al 2 o 3 powder (≤250 mesh); ⑤Ball milling: Put the prepared protective coating in a ball mill and grind it for 1-3 hours to make the composition uniform and to refine the grains, and the particles of the penetrating agent should be refined to no more than 200 mesh; ⑥Drying: Put the ball-milled protective coating in an oven at 120°C for 40 minutes and then dry it; ⑦Embedding: Put the dried protective coating into a corundum crucible, and put the The samples o...

Embodiment 3

[0052] ①Surface pretreatment: remove oxide scales and adherents on the surface of the nickel-based alloy sample or workpiece to keep the surface of the sample clean; Soak for 10 minutes; ③Water washing: Rinse the sample or workpiece after alkali washing with running water, and then dry it for use; ④Preparation of protective coating: Weigh it accurately according to the amount, and the proportion of the protective coating is as follows: 10% Cr powder, 20% Al powder, 10% NH4Cl (analytical pure), 2% Y2O3 powder, the rest is Al 2 o 3 powder (≤250 mesh); ⑤Ball milling: Put the prepared protective coating in a ball mill and grind it for 1-3 hours to make the composition uniform and to refine the grains, and the particles of the penetrating agent should be refined to no more than 200 mesh; ⑥Drying: Put the ball-milled protective coating in an oven at 150°C for 0.5h and then dry it; ⑦Embedding: Put the dried protective coating into a corundum crucible, and put Embed the samples or w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com