Efficient and clean molybdenum smelting method

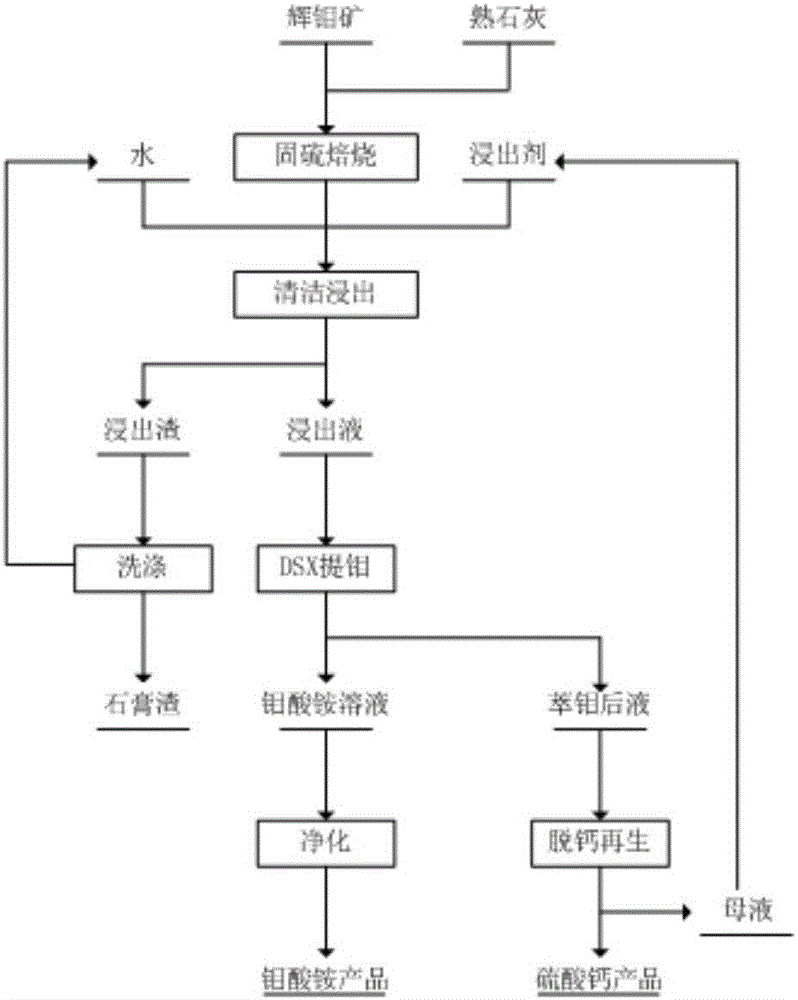

A smelting method and clean technology, applied in the field of efficient and clean molybdenum smelting, can solve the problems of low sulfur content in flue gas, low reagent consumption, short production cycle, etc., and achieve improved recovery rate, low reagent consumption and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 30g molybdenum concentrate (molybdenum grade 41%), 30g slaked lime, MoS 2 The molar ratio of calcium hydroxide to calcium hydroxide is about 1:3, mixed and granulated. After drying, it is baked in a muffle furnace at 450°C for 1 hour, and then heated to 650°C for 1.5 hours. The retention rate and oxidation rate are 99.45% and 99.32%, respectively, and the sulfur fixation rate reaches 98.15%.

[0027] After calcining to 80 mesh, adding 2.5mol / L hydrochloric acid, stirring for 60min under the conditions of liquid-solid ratio of 10:1mL / g, stirring speed of 300rpm, and leaching temperature of 50℃, the leaching rate of molybdenum reached 99.7%.

[0028] The molybdenum-containing acid leaching solution adopts 30% P507-70% sulfonated kerosene at room temperature with three-stage countercurrent extraction, the extraction rate of molybdenum reaches 99.9%, and the negative molybdenum organic phase adopts 1.2mol / L NH 3 ·H 2 O+0.15mol / L NH 4 NO 3 Perform 3 times of reflux back extra...

Embodiment 2

[0031] Take 100g molybdenum concentrate (molybdenum grade 5%), 7.7g slaked lime, MoS 2 The molar ratio of calcium hydroxide to calcium hydroxide is about 1:2. It is mixed and granulated. After drying, it is baked in a muffle furnace at 450°C for 1 hour, and then heated to 620°C for 1 hour. The retention rate and oxidation rate were 99.23% and 99.18%, respectively, and the sulfur fixation rate reached 98.2%.

[0032] After calcining to 100 mesh, adding 2mol / L hydrochloric acid, stirring for 30min under the conditions of liquid-solid ratio of 5:1mL / g, stirring speed of 300rpm, and leaching temperature of 40℃, the leaching rate of molybdenum reached 99.1%.

[0033] The molybdenum-containing acid leaching solution adopts 20% P507-80% sulfonated kerosene at room temperature with three-stage countercurrent extraction, the extraction rate of molybdenum reaches 99.7%, and the negative molybdenum organic phase adopts 1mol / L NH 3 ·H 2 O+0.1mol / L NH 4 Cl was refluxed and stripped three times a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com