Biomass gasified gas system and ash removal and slag discharging dust removal system thereof

A dust removal system and biomass technology, applied in the field of stoves, can solve the problems of incomplete gasification, occupation of labor, inconvenient use of stoves, etc., and achieve the effects of scientific and compact structure, high level of automation, and full utilization of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

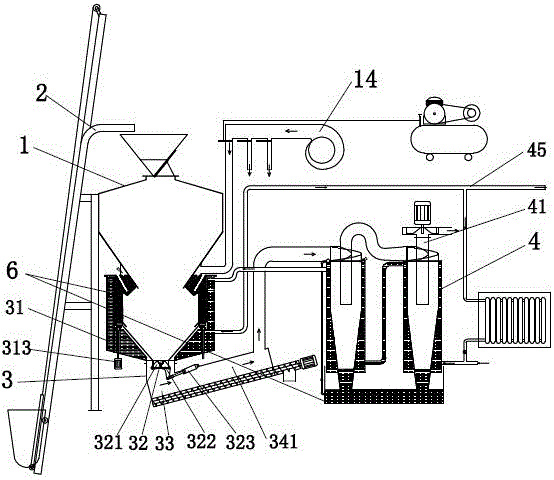

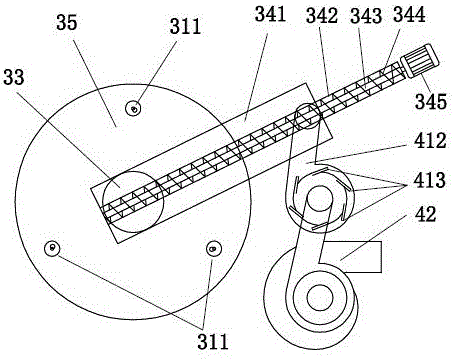

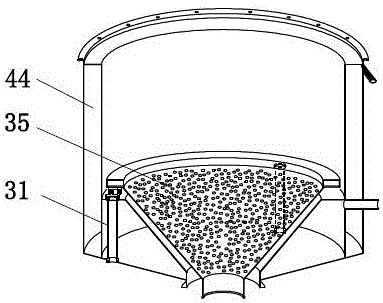

[0032] see figure 1 ~ Figure 6 , the ash discharge and slag removal and dust removal system of the biomass gasification gas system includes a funnel-shaped ash sieve 35, a fire grate 32 that is arranged at the bottom of the funnel-shaped ash sieve 35 and can be opened movably, and an ash receiving bucket 33 that is arranged under the fire grate 32, And the screw conveying device 34 that discharges the furnace ash in the ash hopper 33 .

[0033] see Figure 3~Figure 6 , wherein the ash discharge and slag removal system 3 also includes an eccentric ash sieve device 31 that drives the funnel-shaped ash sieve 35 for horizontal ash sieve action. Motor 313; transmission shaft 312 is arranged on the support seat 311 through bearing 318, and transmission shaft 312 is driven to rotate by sieve dust motor 313, and eccentric wheel 315 is arranged on transmission shaft 312 upper ends, and funnel-shaped ash sieve 35 has upper edge circumferential direction and is provided with 3 ~6 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com