A low-pressure lost-wax precision casting system

A precision casting and low-pressure casting machine technology, applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of casting air hole defects, too late to discharge, mold sand collapse, etc., to reduce production costs, facilitate dumping, and ensure sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

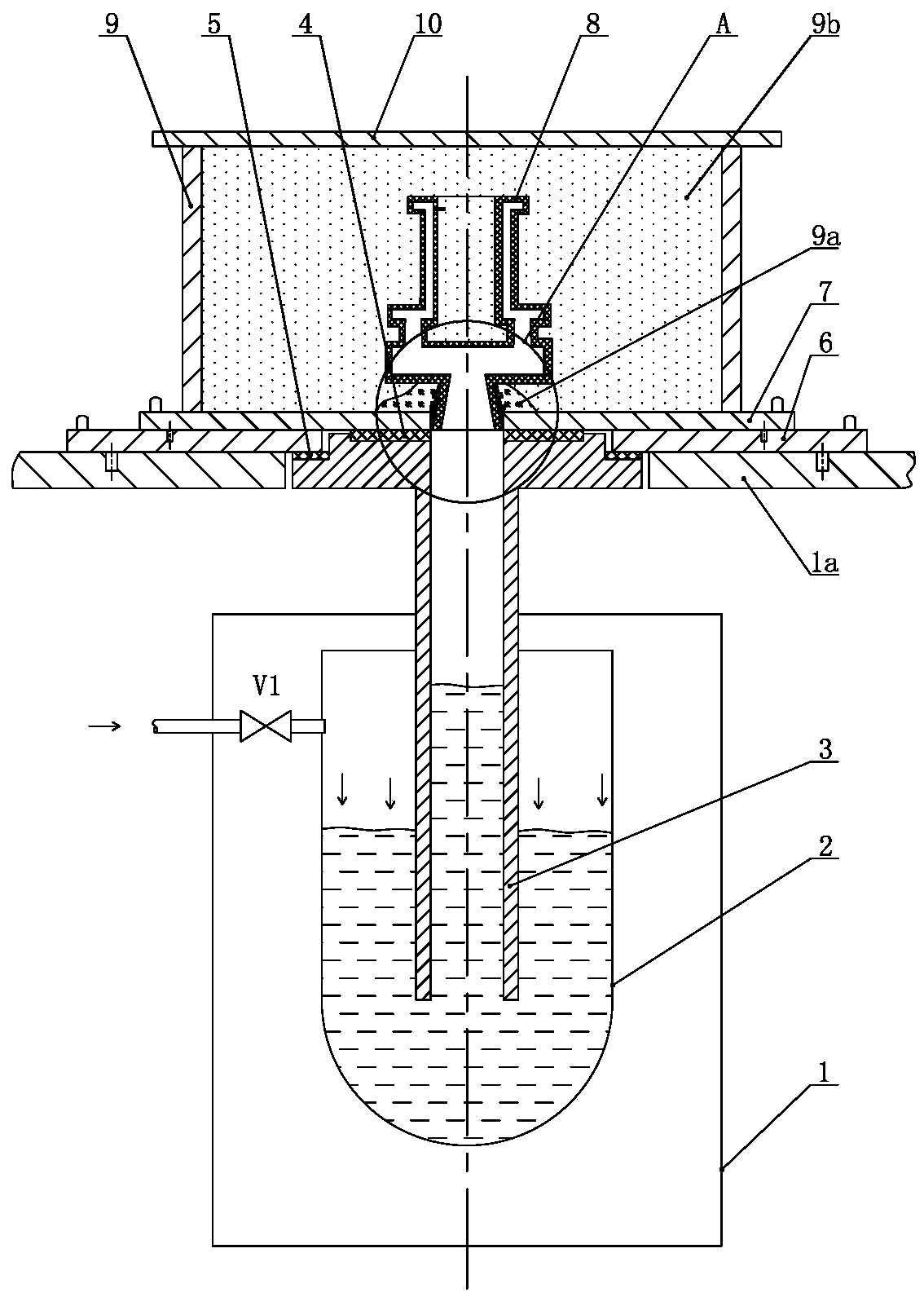

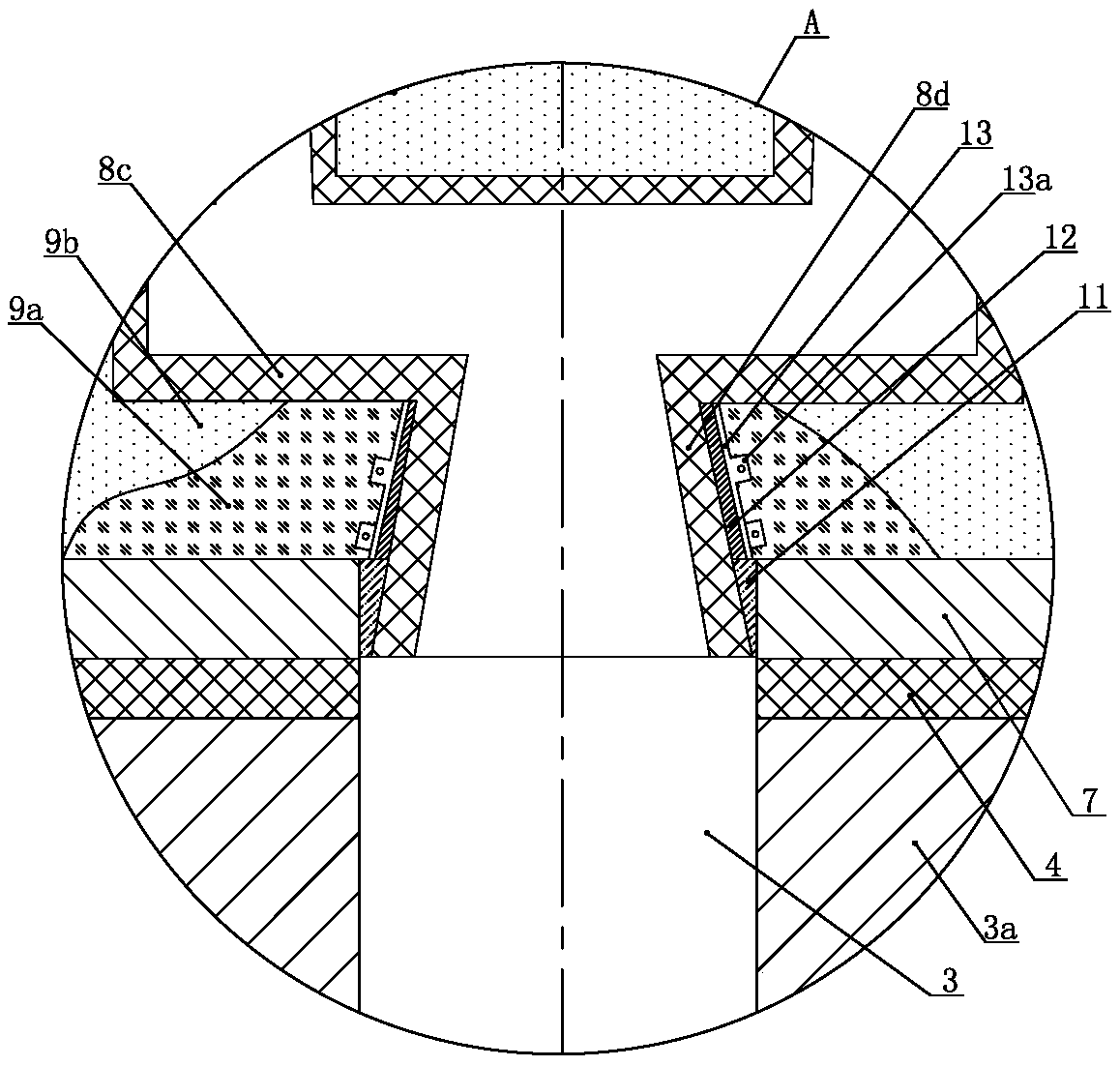

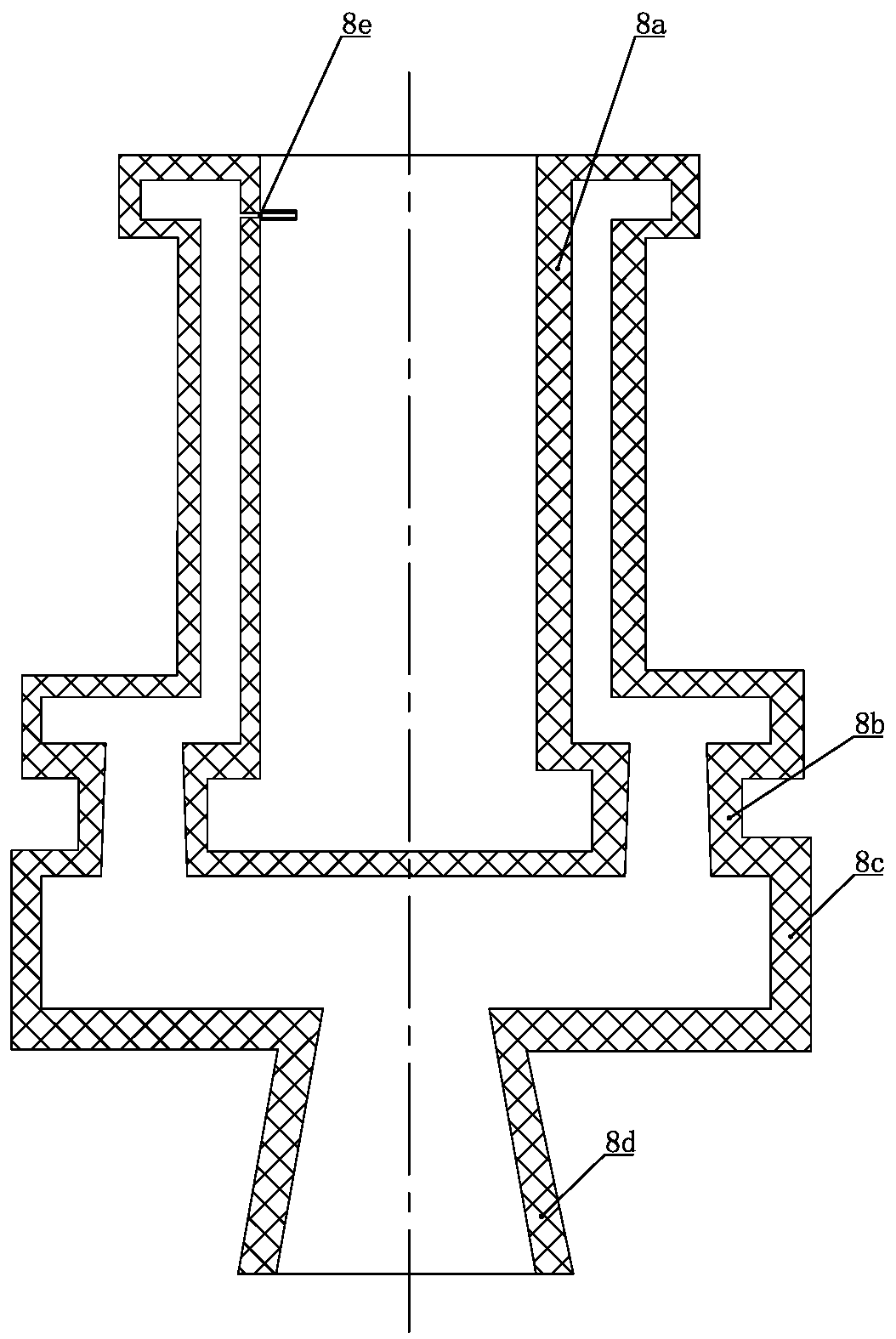

[0035] Such as Figure 1 to Figure 3 As shown, the low-pressure lost-wax investment casting system of the present invention includes a holding furnace 2 located in a low-pressure casting machine 1, a liquid riser 3 is inserted in the liquid phase space of the holding furnace 2, and the side wall of the gas phase space of the holding furnace 2 passes through an air inlet valve. V1 is connected to the compressed air pipe. The top of the liquid riser pipe 3 extends out of the holding furnace 2 and is located in the center hole of the workbench 1a of the low-pressure casting machine. A hoisting steel plate 6 is fixed above the workbench of the low-pressure casting machine, and the top of the hoisting steel plate 6 is fixed. There is a molding steel plate 7, a sand box 9 is fixed above the molding steel plate 7, the top of the sand box 9 is covered with a compression steel plate 10, and a compression device is pressed on the top of the compression steel plate 10, and the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com