Method for preparing polyacrylonitrile antibacterial fiber

A polyacrylonitrile fiber and antibacterial fiber technology, which is applied in fiber type, fiber treatment, biochemical fiber treatment, etc., can solve the problems of antibacterial fiber antibacterial components easy to fall off, short service life, unstable properties, etc., to achieve superior antibacterial performance, The effect of ingenious conception and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

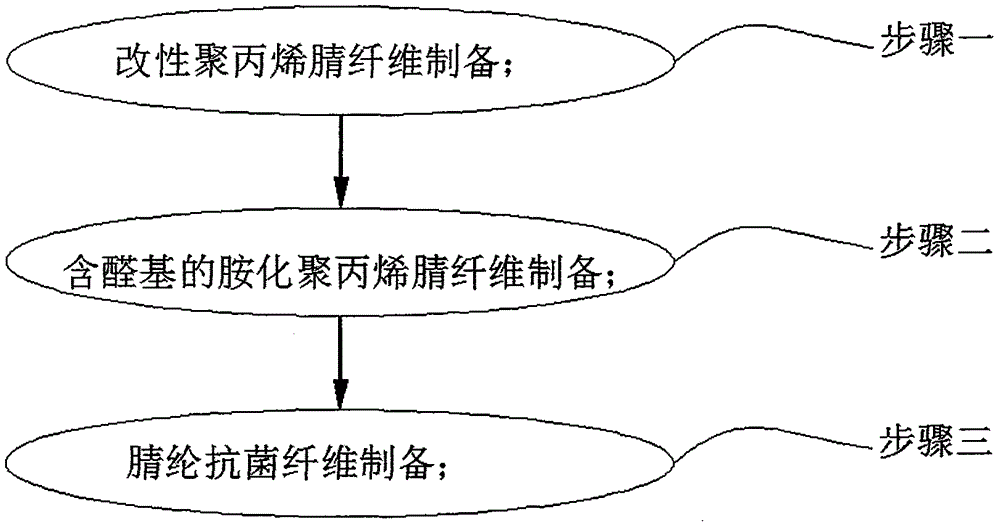

[0022] A method for preparing antibacterial polyacrylonitrile fibers, comprising the following steps: step 1, preparation of modified polyacrylonitrile fibers; step 2, preparation of aminated polyacrylonitrile fibers containing aldehyde groups; step 3, preparation of acrylic antibacterial fibers;

[0023] In the first step, the polyacrylonitrile fiber is put into the alkaline solution of lower alcohol, soaked at 20°C-100°C for 2h-10h, then the fiber is taken out and put into the organic amine solution, and soaked at 40°C-120°C Soak at ℃ for 0.5h-20h, take out the fiber, wash and dry it, and you can get the modified polyacrylonitrile fiber;

[0024] In the second step, the modified polyacrylonitrile fiber is put into the organic solution containing polyaldehyde groups to make it completely submerged, and soaked at 20°C-100°C for 2h-10h, the fiber is taken out, washed and dried. Obtain the aminated polyacrylonitrile fiber containing aldehyde group;

[0025] In the third step, t...

Embodiment 1

[0027] (1) Put 1g of acrylic fiber into a mixed solution of 45ml of methanol, 55ml of water and 1g of sodium hydroxide, soak it at 20°C for 2h, then take out the fiber and put it into diethylenetriamine solution, soak it at 40°C for 0.5 h, taking out the fiber for washing and drying to obtain a modified polyacrylonitrile fiber;

[0028] (2) Put the modified polyacrylonitrile fiber into a glutaraldehyde solution containing 0.1% hydrochloric acid to completely immerse it, and soak it at 20°C for 2 hours, take out the fiber, wash it, and dry it to obtain the aldehyde-based polyacrylonitrile fiber;

[0029] (3) add 0.85g silver nitrate and 0.85g sodium hydroxide in 500ml water, adjust the pH value of this solution with ammoniacal liquor subsequently to be 8, configuration obtains the alkali solution of silver nitrate; Put the fiber gained in step (2) into this silver nitrate and adding polyethylene glycol with a volume fraction of 0.1%, taking it out after soaking at room temperat...

Embodiment 2

[0031] (1) Put 1g of acrylic fiber into a mixed solution of 99ml of ethylene glycol, 1ml of water and 20g of sodium hydroxide, soak it at 100°C for 10h, then take out the fiber and put it into the solution of triethylenetetramine, at 120°C Soak for 20 hours, take out the fiber, wash and dry to obtain the modified polyacrylonitrile fiber;

[0032] (2) Put the modified polyacrylonitrile fiber into a glucose solution containing 0.5% hydrochloric acid to make it completely submerged, and soak it at 100°C for 10 hours, take out the fiber, wash it, and dry it to obtain the aldehyde-based polyacrylonitrile fiber;

[0033] (3) add 1.7g silver nitrate and 1.7g sodium hydroxide in 1L water, adjust the pH value of this solution with ammoniacal liquor subsequently and be 9, configuration obtains the alkaline solution of silver nitrate; Put the fiber gained in step (2) into this silver nitrate and adding 1.0% polyvinylpyrrolidone by volume fraction, soaking at room temperature for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com