A method for synthesizing short-chain aromatic esters using cutinase

A technology of cutinase and aromatic ester, applied in the fields of enzyme engineering and fermentation engineering, can solve the problems of low stability, hindered application, increased concentration, etc., and achieves the effects of improving content, good activity and stability, and simple reaction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Construction and shake flask fermentation of P. pastoris KM71 / pPIC9K-ScCuA

[0032](1) According to the cutinase gene published by NCBI accession number: KF193402, the recombinant plasmid pPIC9K-ScCuA was obtained by chemical synthesis; after linearization by SacI endonuclease, it was electrotransformed into P. pastoris KM71, and the transformation mixture was spread on the MD plate , cultured at 30°C for 2-3d, picked a single colony and planted it on the YPD / G418 plate, the G418 concentration screening gradient was 0mg / mL, 1mg / mL, 1.5mg / mL, 2mg / mL, cultured at 30°C for 1-2d ;Pick the single clone on the YPD / G418 concentration gradient plate in a 50mL Erlenmeyer flask filled with 10mL of YPD medium, culture at 30°C and 200r / min for 20-24h, draw 500μL of the bacterial liquid into a glycerol tube, and store at -80°C refrigerator.

[0033] (2) Pick the single clones on the YPD / G418 concentration gradient plate in 10mL YPD medium, culture in a 200r / min constant ...

Embodiment 2

[0035] Example 2: Fermentation process of P.pastoris KM71 / pPIC9K-ScCuA

[0036] 1. Strain P. pastoris KM71 / pPIC9K-ScCuA.

[0037] 2. Seed culture: Take out the glycerol tube stored in the refrigerator at -80°C, inoculate 200 μL of bacterial solution into 100 mL of seed medium, and cultivate it in a shaker at 30°C and 200 rpm for about 24 hours; the composition of the seed medium is: 10 g of yeast powder / L, peptone 20g / L, YNB 13.4g / L, glycerin 30g / L, biotin 4×10 -4 g / L.

[0038] 3. The amount of fermentation inoculum is 10%.

[0039] 4. Fermentation medium (BSM) composition: CaSO 4 .2H 2 O 0.939g / L, MgSO 4 ·7H 2 O 14.9g / L, KOH4.13g / L, K 2 SO 4 18.2g / L, glycerol 30.0g / L, 85%H 3 PO 4 26.7mL / L, trace element solution PTM 1 4.3mL / L; trace element solution PTM 1 Composition: FeSO 4 ·7H 2 O 65g / L, KI 0.08g / L, H 2 SO 4 5.0g / L, MnSO 4 ·H 2 O 3g / L, CuSO 4 ·5H 2 O 6g / L, H 3 BO 3 0.02g / L, Na 2 MoO 3 2H 2 O 0.2g / L, CoCl 2 0.5g / L, ZnCl 2 20g / L; feed growth medium...

Embodiment 3

[0043] Example 3: Purification and Enzymatic Properties of Recombinant Cutinase

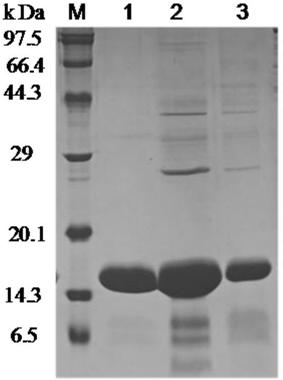

[0044] Add 35% solid ammonium sulfate to the fermentation supernatant for salting out overnight, centrifuge at 8000rpm for 20min at 4°C, dissolve the precipitate with an appropriate amount of 1×Mcilvation buffer with pH 7.0, use a dialysis membrane to remove residual ammonium sulfate, and dialyze the sample The loaded sample was made after filtering through a 0.4um membrane. After DEAE-Sepharose anion exchange resin. The SDS-PAGE electrophoresis of the protein during purification is shown in figure 1 .

[0045] 1. Purification of recombinant cutinase:

[0046] After purification, the specific activity of the recombinant cutinase increased from 90.6U / mg to 149.1U / mg, the purification factor was 1.6 times, and the recovery rate was 31.1%.

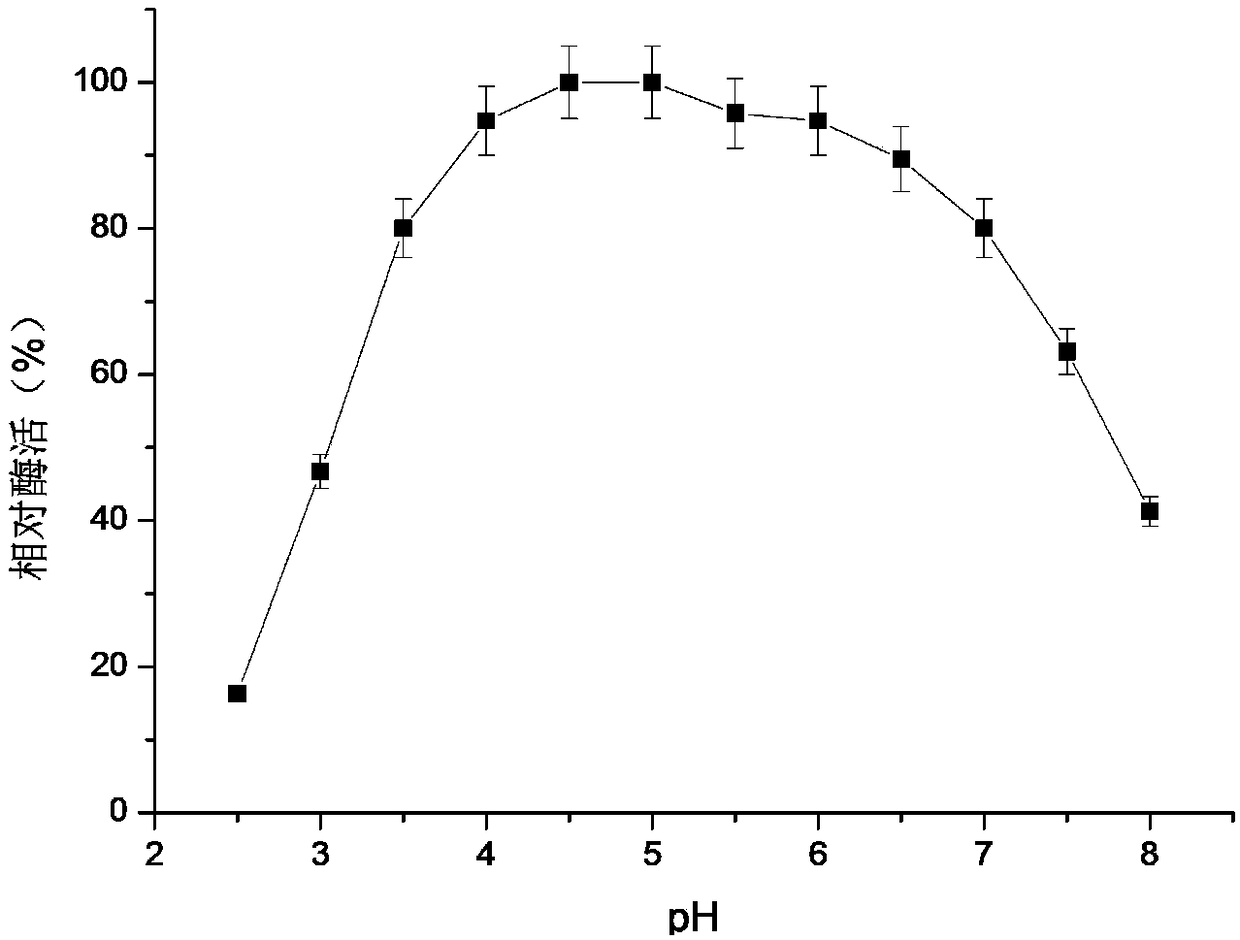

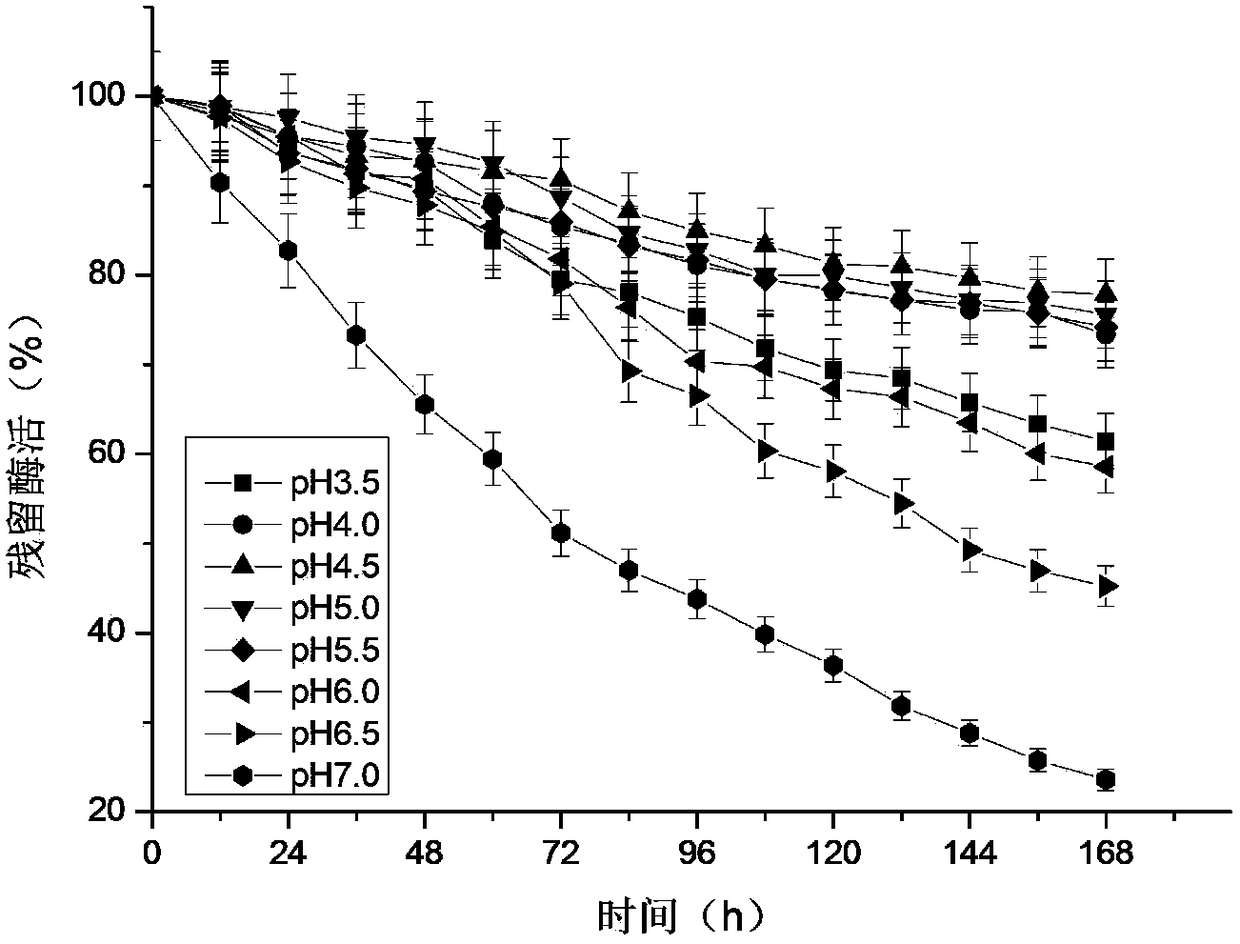

[0047] 2. Enzymatic properties include optimum pH, optimum temperature, pH stability, temperature stability and stability in organic solvents of the recombi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com