Surface treatment method of plastic parts

A technology for surface treatment and plastic parts, applied in the field of surface treatment of plastic parts, can solve the problems of complicated process, high energy consumption, large pollution, etc., and achieve the effects of low raw material price, low energy consumption, and excellent salt spray performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with embodiment the present invention is described in further detail.

[0047] The plastic part surface treatment method comprises the following steps:

[0048] 1) Polish and clean the surface of the workpiece to remove burrs, oil stains and residual release agents, static electricity and dust on the surface of the workpiece;

[0049] 2) Spraying the first organic coating on the surface of the substrate after treatment, the first organic coating is an epoxy-modified acrylic resin passed through a 400 mesh screen and dissolved in a special diluent.

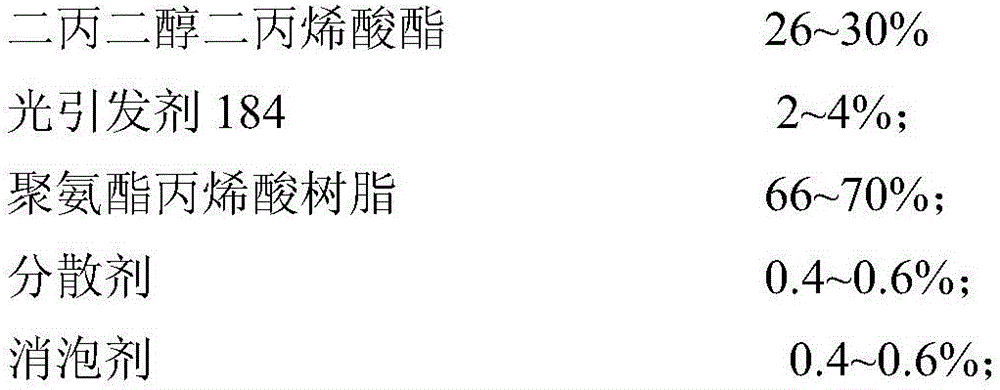

[0050] The quality of described epoxy modified acrylic resin consists of:

[0051]

[0052] The mass composition of special diluent is:

[0053] Trimethylolpropane Triacrylate 66.2%

[0054] Dipropylene glycol diacrylate 33.8%

[0055] Mix the epoxy-modified acrylic resin and the special diluent uniformly at a weight ratio of 1:1 to obtain the first organic coating with a viscosity of 13±3Pa·s. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com