Zinc aluminate nanometer powder and preparing method thereof

A nano-powder, zinc aluminate technology, applied in nanotechnology and other directions, can solve problems such as unsatisfactory effects, and achieve the effects of low cost, controllable appearance, and high fluffy characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Such as figure 1 As shown, the preparation method of zinc aluminate nanopowder in the embodiment of the present application includes as follows:

[0037] 1) Add soluble aluminum salt and zinc salt into the aqueous solution, heat up to 40-70°C under stirring, keep the temperature in the water bath for 20min-60min, and obtain a mixed solution in which the aluminum salt and zinc salt are fully dissolved;

[0038] 2) adding a shape control agent to the mixed solution obtained in step 1), and dissolving the shape control agent under stirring, the concentration of the shape control agent is 0.01-2mol / L;

[0039] 3) Add urea to the mixed solution obtained in step 2), and keep the temperature at 40-70° C. for 1-5 hours to fully dissolve the urea; the molar ratio of the shape control agent to urea is 1:100-1:10;

[0040] 4) Transfer the mixed solution obtained in step 3) to a high-pressure reactor, and react at 120-180° C. for 2-8 hours, wash, filter and dry the obtained produc...

Embodiment 1

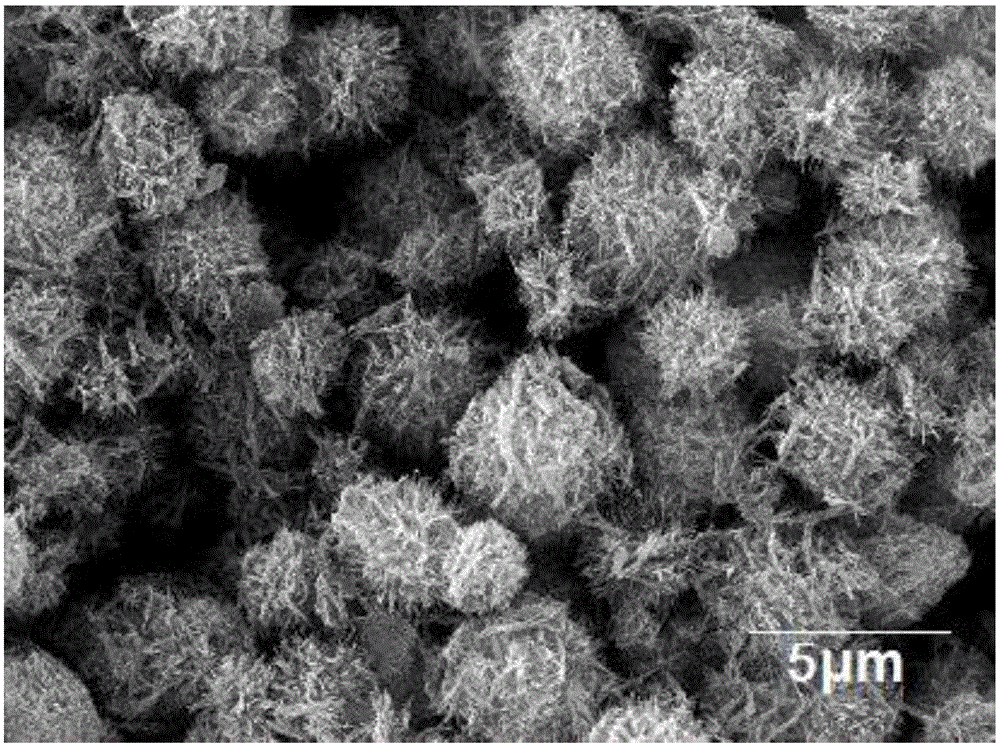

[0049] First, aluminum nitrate and zinc sulfate were added to the aqueous solution to obtain a mixed solution, in which the concentration of aluminum nitrate was 2.0 mol / L, and the concentration of zinc sulfate was 1.0 mol / L. The temperature was raised to 60°C under stirring, and the temperature was kept constant in a water bath for 30 minutes. Then add polyvinyl alcohol to it, and fully dissolve the morphology control agent polyvinyl alcohol under stirring, and the concentration of polyvinyl alcohol formed by the added amount is just 0.25mol / L; then add urea to make the concentration 2.5 mol / L, and kept at 60°C for 3 h; finally, the above solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene. After reacting at 140°C for 5 hours, the product obtained was washed with deionized water and absolute ethanol, filtered with suction, dried in an oven at 80°C for 2 hours, and then roasted in a muffle furnace at 900°C for 2 hours to obtain fluffy sea ...

Embodiment 2

[0052] First, aluminum nitrate and zinc sulfate were added to the aqueous solution to obtain a mixed solution, in which the concentration of aluminum nitrate was 0.1 mol / L, and the concentration of zinc sulfate was 0.05 mol / L. The temperature was raised to 60°C under stirring, and the temperature was kept constant in a water bath for 30 minutes. Then add polyvinyl alcohol therein, and make the morphology control agent fully dissolve under stirring, and the concentration formed by the added amount is just 0.01mol / L; Add urea again, make its concentration be 1.0mol / L, and in Insulate at 60° C. for 3 h; finally transfer the above solution to a stainless steel autoclave lined with polytetrafluoroethylene. After reacting at 150°C for 3h, the obtained product was washed with deionized water and absolute ethanol, filtered with suction, dried in an oven at 75°C for 1.5h, and then roasted in a muffle furnace at 1000°C for 2h to obtain a fluffy sea urchin structure Zinc aluminate nanopo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com