Preparation method of metal-oxide dual-interface catalyst

A technology of oxides and catalysts, which is applied in the field of preparation of metal-oxide double interface catalysts, can solve the problem of no public report of double metal-oxide interface catalysts, etc., and achieves the effect of good isolation and good series reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

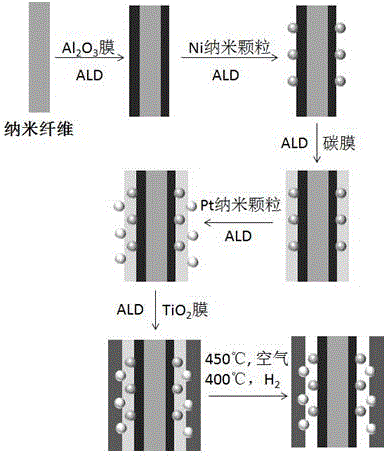

Method used

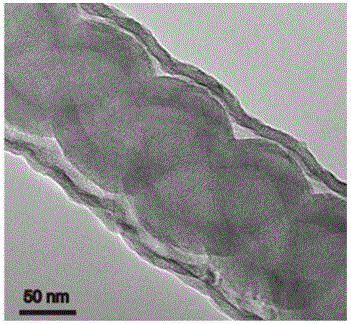

Image

Examples

Embodiment 1

[0031] 1) Mix and disperse nano-carbon spirals (CNCs) with ethanol into a uniform suspension. The sample has a concentration of 0.01g / ml. The sample is coated on the surface of the glass sheet. After evaporation, it is placed in the atomic layer deposition chamber. The pressure of the chamber is 70Pa, the carrier gas flow rate is fixed during the deposition process.

[0032] 2) Using atomic layer deposition technology to deposit aluminum oxide film on the surface of the carbon spiral. The set deposition parameters are: the reaction temperature is 150°C, the temperature of the reaction source trimethylaluminum and water is 25°C, and the nitrogen flow rate is 50 sccm. First pulse the trimethyl aluminum vapor into the deposition chamber, the pulse time is 0.02s, the hold time is 5s, and the purge time is 15s; then the water vapor is pulsed into the deposition chamber, the pulse time is 0.1s, the hold time is 15s, and the blow The scanning time is 20s, and a deposition cycle is comp...

Embodiment 2

[0040] The experiment was performed using the same method as in Example 1, and the difference from Example 1 was that the number of cycles of the sacrificial layer polyimide organic film was 80 cycles. At this time Al 2 O 3 / Ni-Pt / TiO 2 The yield of aniline on the catalyst reached 50% within 30 minutes, and reached more than 98% within 180 minutes. This indicates that the activity of the catalyst can be changed by changing the thickness of the sacrificial layer.

Embodiment 3

[0042] 1) Mix and disperse carbon nanotubes with ethanol to form a uniform suspension. The sample concentration is 0.03g / ml, and it is coated on the surface of the glass sheet. After evaporation, it is placed in an atomic layer deposition chamber. The chamber pressure is 50Pa. The flow of carrier gas is fixed during the process.

[0043] 2) Using atomic layer deposition technology to deposit zinc oxide film on the surface of carbon nanotubes. The set deposition parameters are: the reaction temperature is 100°C, the temperature of the reaction source diethylzinc and water is 25°C, and the nitrogen flow rate is 40 sccm. First pulse diethylzinc vapor into the deposition chamber, the pulse time is 0.02s, the hold time is 5s, and the purge time is 15s; then the water vapor is pulsed into the deposition chamber, the pulse time is 0.1s, the hold time is 15s, and the blow The scanning time is 20s, and a deposition cycle is completed so far. Repeated 150 cycles to obtain zinc oxide film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com