Thermochromic intelligent film and preparation method therefor

A smart film and thermochromic technology, applied in the field of thermochromic smart film and its preparation, to achieve good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of thermochromatic intelligent film, the step comprises:

[0034] a. providing a substrate 1;

[0035] b. Depositing a first dielectric layer 2, an infrared reflective layer 4, a thermochromic functional layer 7, a first barrier layer 8, a second barrier layer 9 and a second dielectric layer 10 on the substrate 1 by vacuum magnetron sputtering, Wherein the first barrier layer 8 and the second barrier layer 9 are sputtered with different targets, the first barrier layer 8 is a metal oxide, nitride or oxynitride, and the second barrier layer 9 is a metal film;

[0036] c. Anneal the coated glass.

[0037] In the preparation method of the thermochromic intelligent film layer described in the present invention, the annealing treatment can adopt any one of infrared radiation lamp annealing, flash lamp annealing, laser annealing and tempering annealing. In the present invention, the annealing treatment is preferably carried out by means of infrared ra...

Embodiment 1

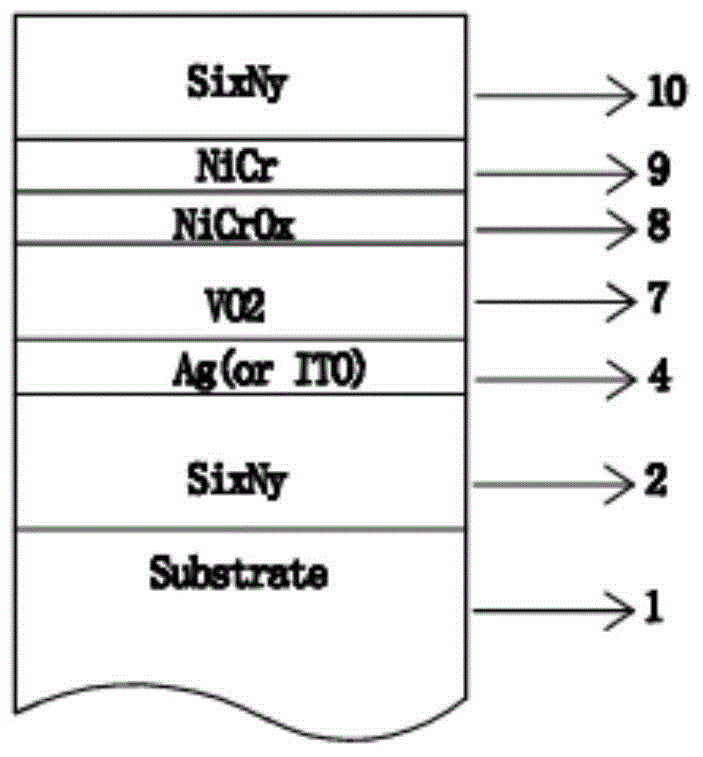

[0039] figure 1 It is the thermochromatic smart film section of specific embodiment 1 picture The thermochromic smart film includes a substrate 1 (including transparent glass or colored glass with a thickness of 1 to 10 mm, preferably with a thickness of 4 mm to 6 mm) and a first dielectric layer 2 (in contact with the glass substrate) and an infrared reflective layer on the substrate in sequence. Layer 4, thermochromic functional layer 7, first barrier layer 8 (adjacent to thermochromic functional layer 7), second barrier layer 9 (connected to first barrier layer 8) and second dielectric layer 10 (located on the second barrier layer 9, which is also the topmost layer of the composite film layer). as shown in the picture The above-mentioned non-limiting material film layers 1-10 form a thermochromic intelligent film film layer with adjustable heat gain as the ambient temperature changes, and this film layer can be deposited on plastic substrates, glass substrates, metal ...

Embodiment 2

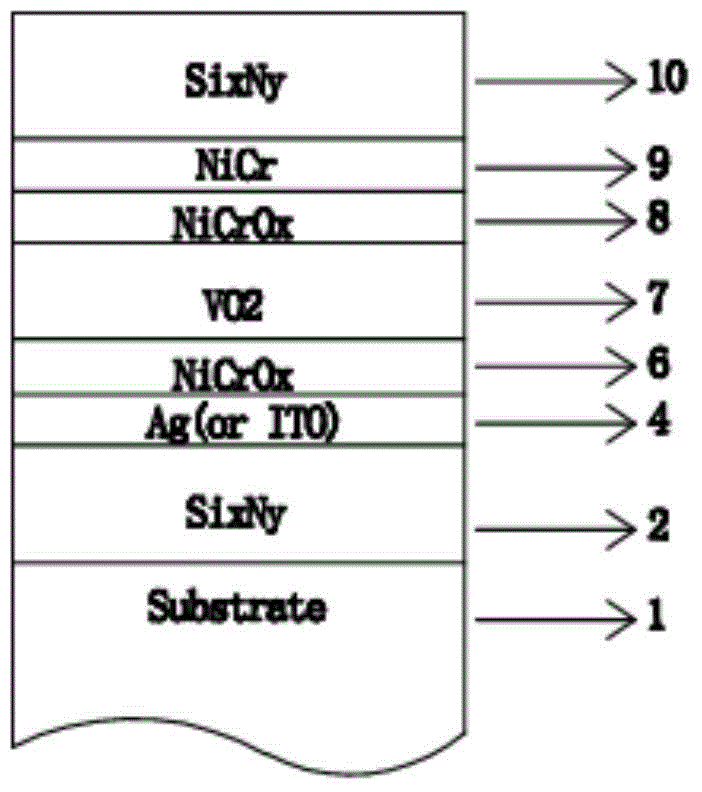

[0050] figure 2 Be the thermochromatic smart film section of specific embodiment 2 picture The thermochromic smart film includes a substrate 1 (including transparent glass or colored glass with a thickness of 1 to 10 mm, preferably with a thickness of 4 mm to 6 mm) and a first dielectric layer 2 (in contact with the glass substrate) and an infrared reflective layer on the substrate in sequence. Layer 4, first barrier layer 6, vanadium oxide film layer 7, first barrier layer 8 (close to vanadium oxide film layer 7), second barrier layer 9 (connected with first barrier layer 8) and second dielectric layer 10 (It is located on the second barrier layer 9 and is also the topmost layer of the composite film layer). as shown in the picture The above-mentioned non-limiting material film layer 1-10 has formed the thermochromatic intelligent film film layer that has the heat that can be adjusted with the change of ambient temperature, and this film layer can be deposited on plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com