Graphene material based on solid state mechanochemical reactor and preparation method of graphene material

A technology of chemical reactor and graphene, which is applied in the field of graphene material and its preparation based on solid-phase force chemical reactor, can solve the problem that batch production technology and high performance cannot be balanced, and large-scale production and preparation cannot be realized. Harsh conditions and other problems, to achieve the effect of low production cost, good heat, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

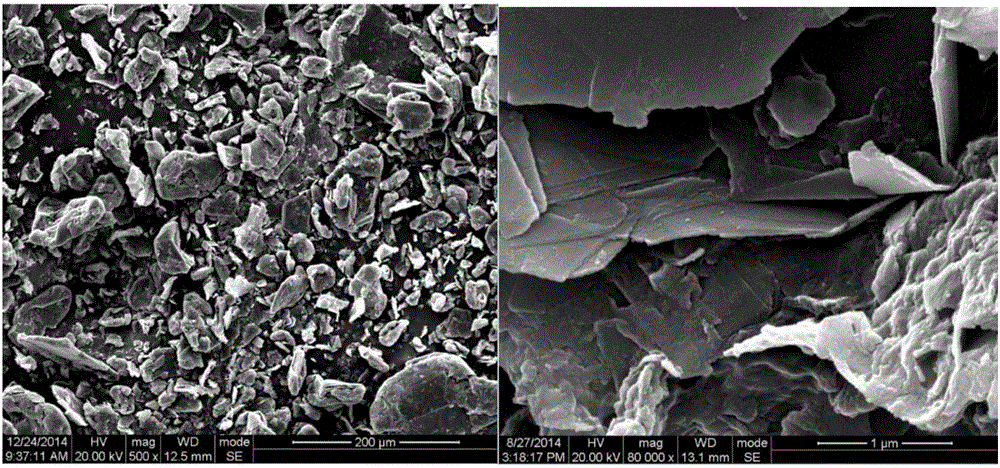

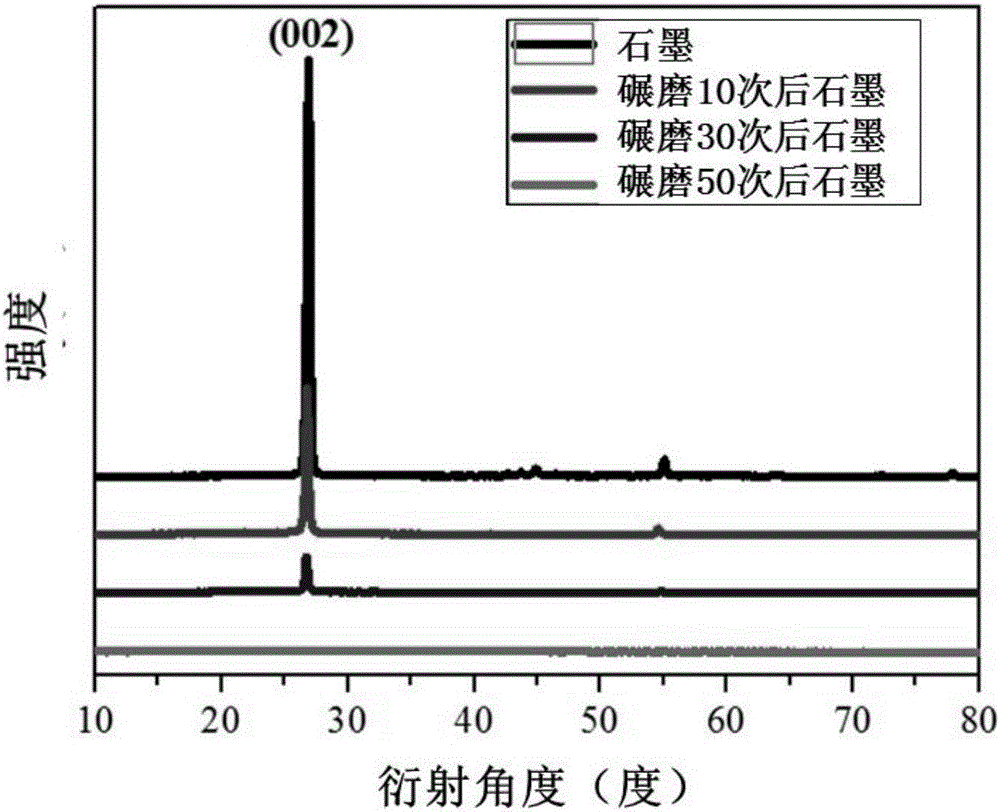

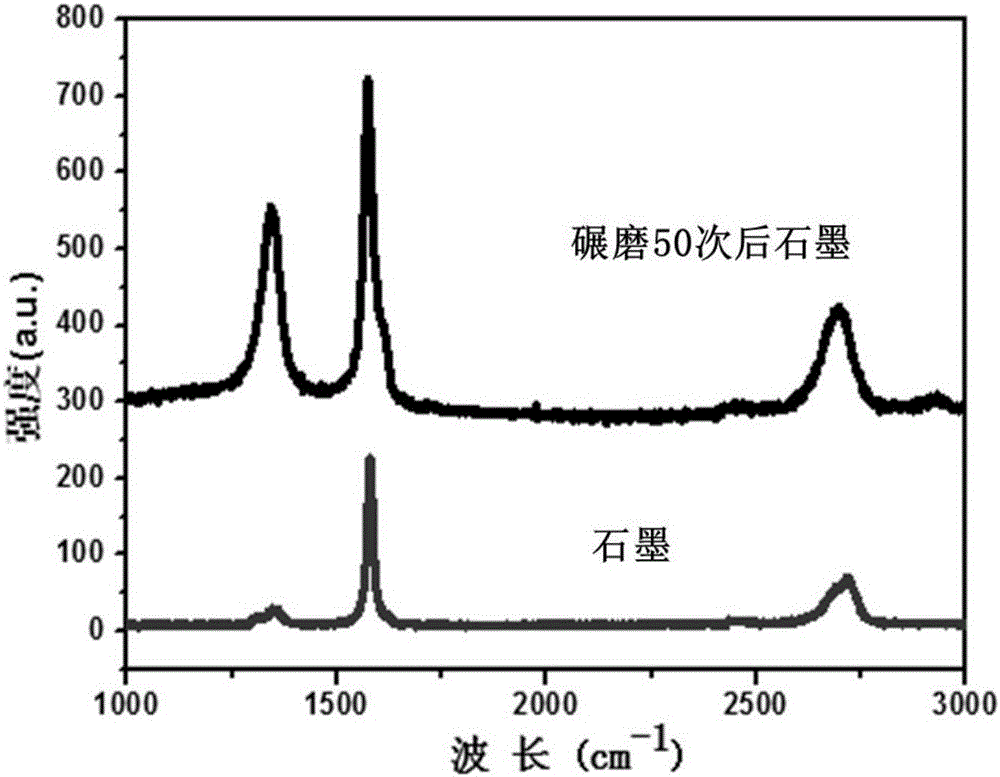

[0051] Embodiment one uses the inventive method to prepare graphene

[0052] Dry graphite flakes (325 mesh, carbon content>99%) and sodium chloride at a temperature of 90° C. for 4 hours, weigh 30 g of graphite flakes and 1 kg of sodium chloride and add them to a high-speed mixer to mix evenly, then place them in a solid In the phase force chemical reactor, the cooling circulating water at room temperature is fed into the cooling device during the milling process, and the temperature of the disc surface is controlled at 25°C, the pressure is 15KN, the speed is 150 rpm, and the circular grinding is performed 50 times to obtain graphene. Composite with NaCl. Transfer the graphene and sodium chloride composite material into distilled water, remove the sodium chloride therein, and then treat the obtained product with 1mol / L hydrochloric acid for 12 hours, and centrifuge and wash for 20 minutes at a speed of 8000 rpm to obtain The precipitate was vacuum-dried at 60°C for 12 hours ...

Embodiment 2

[0053] Embodiment two uses the method of the present invention to prepare graphene

[0054] Dry graphite flakes (325 mesh, carbon content>99%) and sodium chloride at a temperature of 90° C. for 4 hours, weigh 30 g of graphite flakes and 1 kg of sodium chloride and add them to a high-speed mixer to mix evenly, then place them in a solid In the phase force chemical reactor, cooling circulating water at room temperature is introduced during the milling process, and the temperature of the disc surface is controlled at 30°C, the pressure is 20KN, the speed is 150 rpm, and the grinding cycle is 50 times to obtain graphene and chloride. Sodium composites. Transfer the graphene and sodium chloride composite material into distilled water, remove the sodium chloride therein, and then treat the obtained product with 1mol / L dilute sulfuric acid for 12 hours, and centrifuge and wash it for 20 minutes at a speed of 8000 rpm The obtained precipitate was vacuum-dried at 60° C. for 12 hours t...

Embodiment 3

[0055] Embodiment three uses the method of the present invention to prepare graphene

[0056] Mix graphite powder (325 mesh, carbon content>99%) with SiO 2 Dry at 90°C for 6 hours, weigh 10g of graphite powder and 1kg of SiO 2 Add it into a high-speed mixer and mix evenly, then put it into a solid-phase force chemical reactor, pass cooling circulating water at room temperature during the milling process, and control the temperature of the disc surface to 40°C, the pressure to 25KN, and the speed to 200 rpm. Circular grinding 50 times to obtain graphene and SiO 2 of composite materials. Graphene and SiO 2 The composite material is dispersed in hydrofluoric acid, and then the graphene is separated by centrifugation, and the centrifugation is repeated 3 times to completely remove the SiO 2, and then the product obtained was treated with 1mol / L dilute sulfuric acid for 12 hours, and the precipitate obtained after centrifugation and washing for 30 minutes at a speed of 5000 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com