Catalyst for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester, preparation method thereof, application thereof, and method for preparing low carbon alcohol by hydrogenation of short chain fatty acid ester

A technology for producing low-carbon alcohols from fatty acid esters, which is applied to the catalyst, production method, and use of short-chain fatty acid esters to produce low-carbon alcohols, and the field of short-chain fatty acid esters to produce low-carbon alcohols. High conversion rate and selectivity can be achieved due to problems such as low sex and space-time yield, high raw material gas purity requirements, and short process routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The method for preparing low-carbon alcohol catalyst by hydrogenation of short-chain fatty acid ester of the present invention comprises the following steps:

[0043] 1) preparing cuproammonia solution A and acidic solution B of cerium and zirconium;

[0044] 2) Add solution B dropwise to solution A, mix, and age the mixed solution;

[0045] 3) Heating the mixed solution to 70-95°C until the pH value is 6-7, and the product precipitates out;

[0046] 4) filtering, washing, drying and calcining the precipitated product to obtain the catalyst.

[0047] Another method for preparing a low-carbon alcohol catalyst by hydrogenation of short-chain fatty acid esters of the present invention comprises the following steps:

[0048] 1) prepare the acidic aqueous solution of copper salt, zirconium salt, cerium salt;

[0049] 2) adding urea to the acidic aqueous solution to obtain a uniformly mixed solution;

[0050] 3) Heating the mixed solution to 70-95°C and refluxing until th...

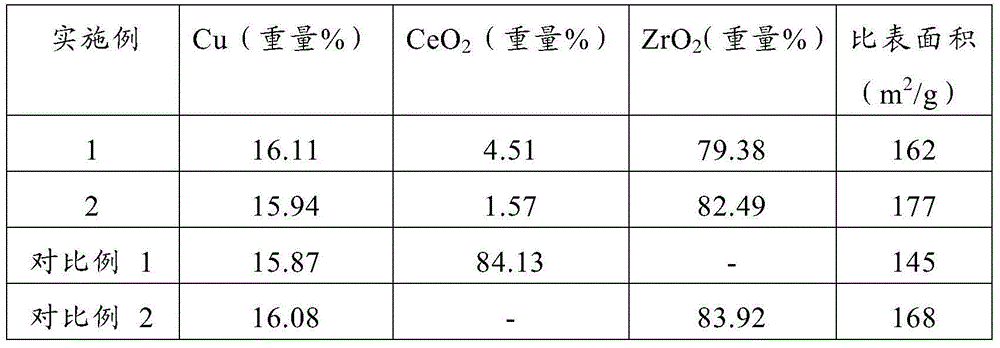

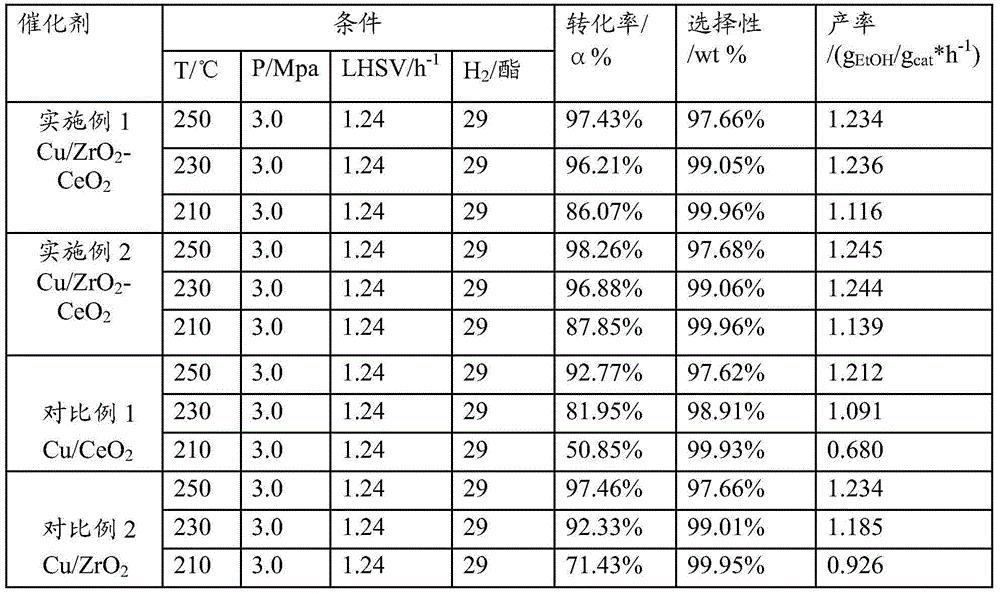

Embodiment 1

[0081] Weigh 5g of copper nitrate trihydrate, add 20g of concentrated ammonia solution with a weight fraction of 28%, and dissolve it in 200mL of deionized water to form copper ammonia solution A. Then weigh 15 g of cerium nitrate and 7 g of zirconyl nitrate, mix and dissolve in 200 mL of aqueous solution to form solution B. Slowly add solution B dropwise to solution A and keep stirring to form a mixed solution, age the mixed solution at room temperature for 4 hours, then move to an oil bath at 90°C, heat and keep stirring, when the pH value of the solution drops to At 7.0, stop stirring, filter the solution while it is hot, wash the obtained filter cake with ionized water, dry it at 120°C for 12 hours, place it in a muffle furnace, raise the temperature at 1°C / min to 450°C and roast it at a constant temperature for 4 hours, After cooling to room temperature, then, H 2 / Ar mixed gas, the temperature was raised to 300°C at 1°C / min, and reduced for 4 hours to obtain catalyst A....

Embodiment 2

[0083]Weigh 5g of copper nitrate trihydrate, 15g of cerium nitrate, 7g of zirconium oxynitrate dissolved in 200mL of deionized water to form a solution, adjust the pH of the solution to 3 with nitric acid, add 10g of urea to form a mixed solution, and put the mixed solution The three-necked flask was moved to a 90°C oil bath, stirred, and heated to reflux. When the pH value of the solution drops to 7.0, stop stirring, filter the solution while it is hot, wash the obtained filter cake with ion water, dry it at 120°C for 12 hours, put it in a muffle furnace, and raise the temperature to 450°C at 1°C / min Calcined at constant temperature for 4 hours, cooled to room temperature, then, H2 / Ar mixed gas was introduced, the temperature was raised to 300°C at 1°C / min, and reduced for 4 hours to obtain catalyst B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com