Probiotic factor-containing white granulated sugar substitution and preparation method thereof

A technology of probiotic factors and substitutes, which is applied in the field of white sugar substitutes containing probiotic factors and its preparation, can solve problems such as difficulty in ensuring product uniformity and sweetness, poor product uniformity, and long production cycle. Achieve the effect of improving the overall economic benefits of the product, solving the particle size difference, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

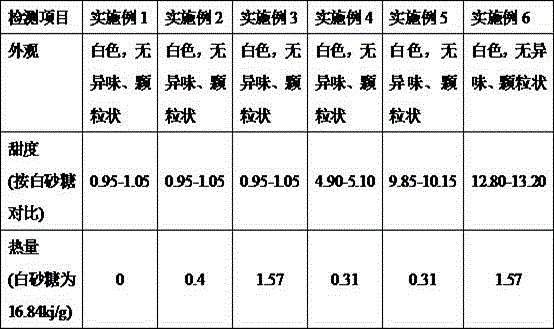

Examples

Embodiment 1

[0029] The white granulated sugar substitute containing probiotic factor of the present invention is made up of the following components by weight percentage:

[0030] Erythritol: 99.81%

[0031] Fructose-oligosaccharide (prebiotic factor): 0.04%

[0032] Steviol Glycosides: 0.12%

[0033] Mogroside: 0.03%.

[0034] Heat erythritol in an oil bath to 114-118°C while stirring, and make erythritol ointment or semi-dissolved state; then add fructooligosaccharide (prebiotic factor), steviol glycoside, mogroside sugar alcohol; continue to stir evenly , transport the slurry to the roller-type extrusion granulator equipment; then pass through the roller-type extrusion granulation to form; the formed product is bagged, boxed, and then packed in a box; the packaged product is inspected and passed library. The sweetness of the product of this embodiment is equivalent to that of white granulated sugar, contains prebiotic factors, and its calories are basically zero.

Embodiment 2

[0036] The white granulated sugar substitute containing probiotic factor of the present invention is made up of the following components by weight percentage:

[0037] Erythritol: 92.847%

[0038]Fructose-oligosaccharide (prebiotic factor): 7.00%

[0039] Steviol Glycosides: 0.083%

[0040] Mogroside: 0.07%.

[0041] Heat erythritol in an oil bath to 114-118°C while stirring, and make erythritol ointment or semi-dissolved state; then add fructooligosaccharide (prebiotic factor), steviol glycoside, mogroside sugar alcohol; continue to stir evenly , transport the slurry to the roller-type extrusion granulator equipment; then pass through the roller-type extrusion granulation to form; the formed product is bagged, boxed, and then packed in a box; the packaged product is inspected and passed library. The sweetness of the product of this embodiment is equivalent to that of white granulated sugar, contains more probiotic factors, and the calories are only below 3% of that of whi...

Embodiment 3

[0043] The white granulated sugar substitute containing probiotic factor of the present invention is made up of the following components by weight percentage:

[0044] Erythritol: 74.82%

[0045] Fructose-oligosaccharide (prebiotic factor): 25.00%

[0046] Steviol Glycosides: 0.09%

[0047] Mogroside: 0.09%.

[0048] Heat erythritol in an oil bath to 114-118°C while stirring, and make erythritol ointment or semi-dissolved state; then add fructooligosaccharide (prebiotic factor), steviol glycoside, mogroside sugar alcohol; continue to stir evenly , transport the slurry to the roller-type extrusion granulator equipment; then pass through the roller-type extrusion granulation to form; the formed product is bagged, boxed, and then packed in a box; the packaged product is inspected and passed Storehouse; The sweetness of this embodiment product is suitable with the sweetness of white granulated sugar, contains a large amount of probiotic factors, but its calorie is only below 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com