Grease composition and food

An oil composition and a technology for the composition, which are applied in the directions of edible oil/fat, food science, cocoa, etc., can solve the problems of product stability limitation, difficulty in reaching zero trans fatty acid level, and high cost, and achieve good operating performance, refreshing and refreshing. Effect of taste, good health concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

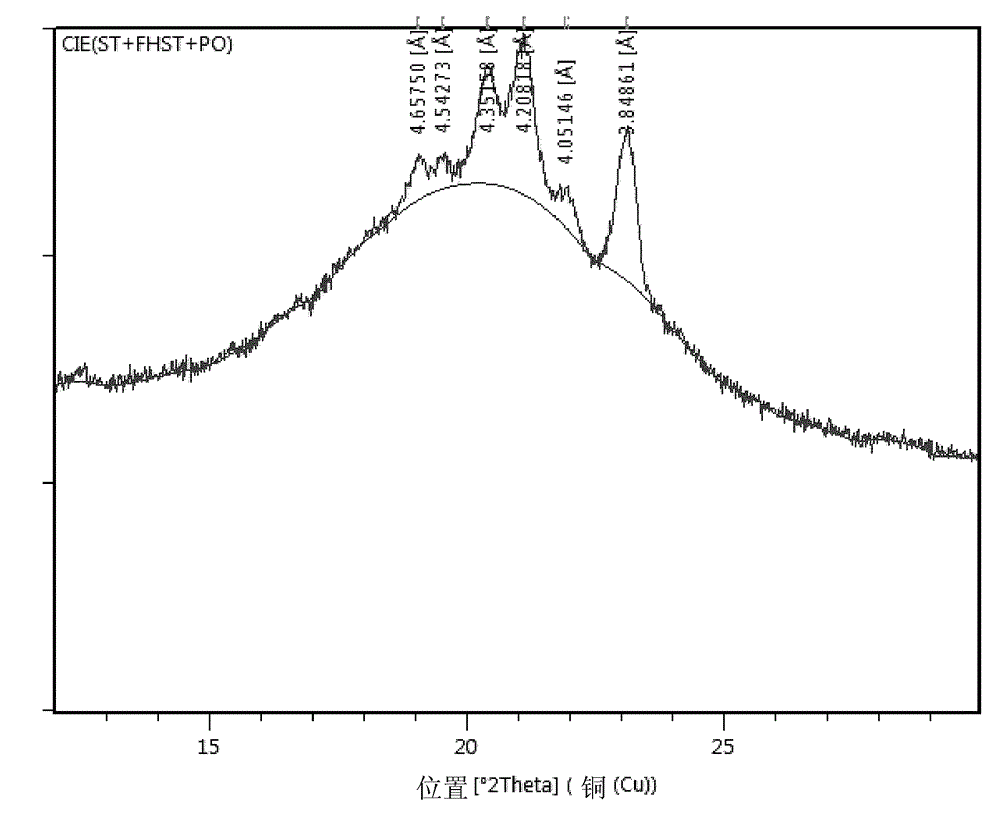

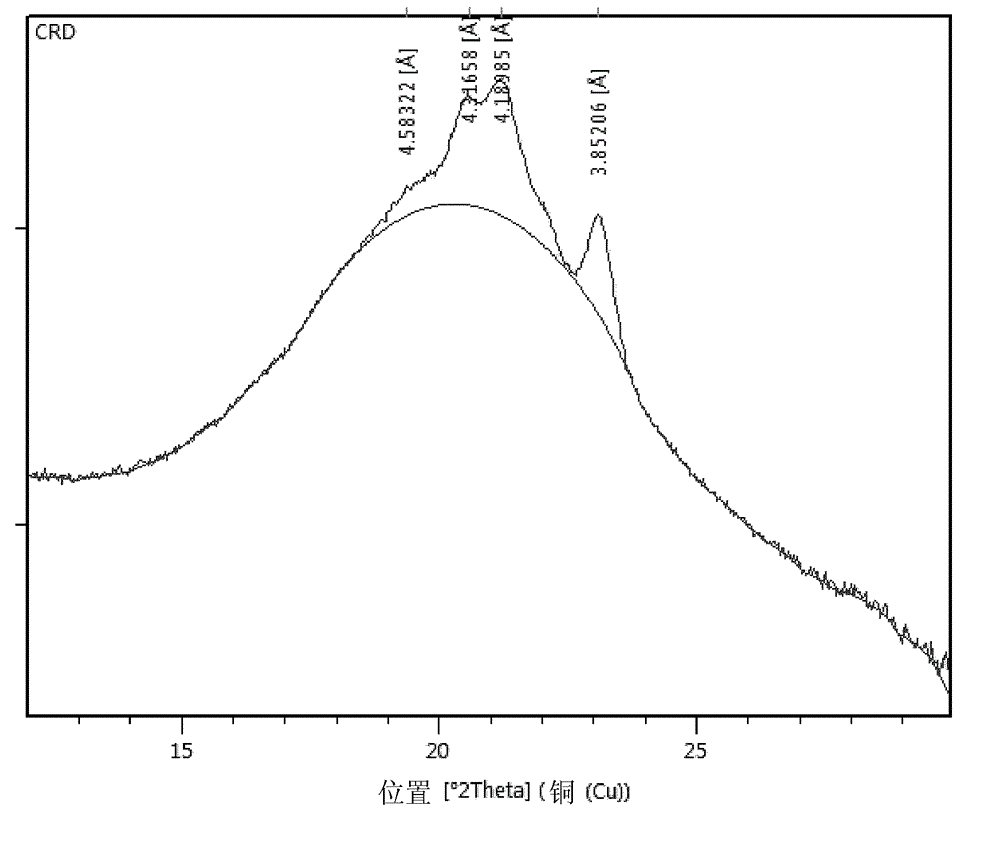

Image

Examples

preparation example Construction

[0088] Preparation method of oil composition

[0089]Another object of the present invention is to provide a method for preparing an oil composition, including (1) contacting and esterifying vegetable oil with at least one selected from palm oil, shea butter, tallow fat or their fractionated oils , or contact and esterify the vegetable oil with at least one selected from perhydrogenated oils; or contact and esterify the vegetable oil with at least one selected from fractionated oils and at least one oil in perhydrogenated oils; (2) Fractionally extracting the esterified oil obtained in step (1) to obtain an oil composition.

[0090] In a preferred embodiment of the present invention, in the step (1), the vegetable oil is mixed with palm stearin, palm olein, palm oil intermediate fraction, shea stearin, and shea butter oil At least one contact and esterification of vegetable oil and at least one selected from fully hydrogenated palm stearin or fully hydrogenated soybean oil an...

Embodiment 1

[0124] According to the formula in Table 1, the following vegetable oils were mixed (total: 2000g) and chemically transesterified. Reaction conditions: reaction temperature 105°C, vacuum environment, catalyst: sodium methoxide, addition amount 0.3%, reaction time 30min.

[0125] Table 1

[0126] ingredients content% Fully Hydrogenated Palm Stearin 15 palm oil 45 palm stearin 40

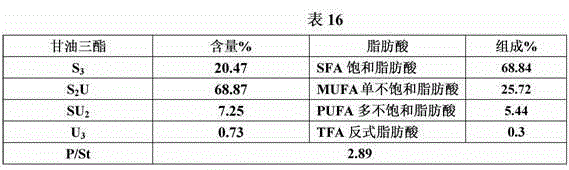

[0127] The above reaction product was frozen and fractionated, specifically as follows, the oil was completely melted at 60°C and kept for 30 minutes. 0.2 ℃ min to 45 ℃, keep 500 min, press filter to remove high melting point components. The liquid portion was melted again at 60 °C for 30 min. 0.5°C / min to 25°C, keep for 600min, press filter to remove the low melting point part, and the remaining stearin is the obtained fractionation product. After degumming, decolorization, and deodorization, oil 1 was obtained, and its triglyceride and fatty acid compositions we...

Embodiment 2

[0133] In the same manner as in Example 1, the following vegetable fats and oils (2000 g in total) were mixed and chemically transesterified.

[0134] Table 4

[0135] ingredients content% Fully Hydrogenated Palm Stearin 20 palm oil 40 palm stearin 40

[0136] In the same manner as in Example 1, the reaction product was frozen and fractionated, specifically as follows, the oil was completely melted at 60° C. and kept for 30 minutes. 0.15°C / min to 47°C, keep for 500min, press filter to remove high melting point components. The liquid portion was melted again at 60 °C for 30 min. 0.4 ℃ / min to 38 ℃, keep 300min, continue to filter to remove the high melting point part. The liquid portion was melted again at 60 °C for 30 min. 0.5°C / min to 26°C, keep for 600min, press filter to remove the low melting point part, and the remaining stearin is the obtained fractionation product. After degumming, decolorization, and deodorization, oil 2 was obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com