Insulating paint and preparation method thereof

A technology of insulating varnish and nano-carbon crystal, which is applied in the field of coatings, can solve the problems of low output of solvent-free insulating varnish and high-solid insulating varnish, failure to meet market demand, and accelerated insulation aging speed, so as to improve microhardness and plumpness Good, no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 nanometer carbon crystal

[0029] Its process flow diagram is as follows figure 1 As shown, the steps are:

[0030] (1) Preliminary crushing: firstly, the diamond raw material is sent into the crushing cavity of the mechanical crusher, and is crushed by the high-speed rotating hammer head inside the crusher. The material stays in the crusher for re-crushing, and the granular material filtered through the finest sieve in the lower layer of the crusher is collected by the sieve plate (the mesh number of the sieve is not less than 32 mesh), while the material filtered by other mesh sieves can be used as Coarse materials are sold or used to prepare materials with other particle sizes; particles above 32 mesh are used for primary particle size separation by a multi-layer vibrating sieve machine. Cloth, the coarse material selected by the 40-mesh sieve is returned to the mechanical crusher for re-crushing, the material collected by the 40-mes...

Embodiment 2

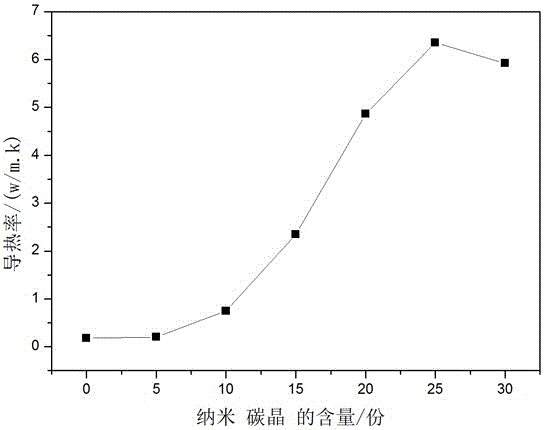

[0035] An insulating varnish, made of the following raw materials in parts by weight: 25 parts of nano-carbon crystals, 35 parts of polyimide, 35 parts of epoxy resin, 1 part of dispersant, 1 part of leveling agent, corrosion inhibitor (phosphate 317) 0.5 parts, defoamer 2 parts, lysozyme 0.5 parts.

[0036]Wherein, the leveling agent is a mixture of silicone oil and polydimethylsiloxane, and the dosage ratio is 1:1.

[0037] The nano-carbon crystals are subjected to the following surface functionalization treatment: the nano-carbon crystals are added to concentrated HNO 3 and concentrated H 2 SO 4 In the mixed solution, heated to reflux and centrifuged, the precipitate was washed with deionized water until the pH was 6.0, and the molar concentration was 0.1mol L - 1 Na 2 SiO 3 9H 2 Wash with O solution, ultrasonically disperse for 1 h, and then use a molar concentration of 0.1mol L -1 After washing with HCL and ultrasonically dispersing for 2 hours, wash with deionize...

Embodiment 3

[0040] An insulating varnish, made of the following raw materials in parts by weight: 5 parts of nano-carbon crystals, 40 parts of polyimide, 50 parts of epoxy resin, 0.1 part of dispersant, 0.1 part of leveling agent, corrosion inhibitor (phosphate 317) 0.2 parts, defoamer 1.6 parts, lysozyme 3 parts.

[0041] The nano-carbon crystals are subjected to the following surface functionalization treatment: the nano-carbon crystals are added to concentrated HNO 3 and concentrated H 2 SO 4 In the mixed solution, heated to reflux and centrifuged, the precipitate was washed with deionized water until the pH was 5.0, and the molar concentration was 0.5mol L - 1 Na 2 SiO 3 9H 2 Wash with O solution, ultrasonically disperse for 2 hours, and then use a molar concentration of 0.5mol L -1 After washing with HCL and ultrasonic dispersion for 1, wash with deionized water and dry; the concentrated HNO 3 and concentrated H 2 SO 4 The mass ratio is 1:5.

[0042] Among them, the leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com