Glass fiber/thermoplastic plastic granules and method for preparing same

A thermoplastic and glass fiber technology, applied in the field of thermoplastic particles and their preparation, glass fiber/thermoplastic particles and their preparation, can solve the problems of large diameter, poor wear resistance and low strength of centrifugal glass fibers, and achieve excellent Mechanical properties, low cost, anti-melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

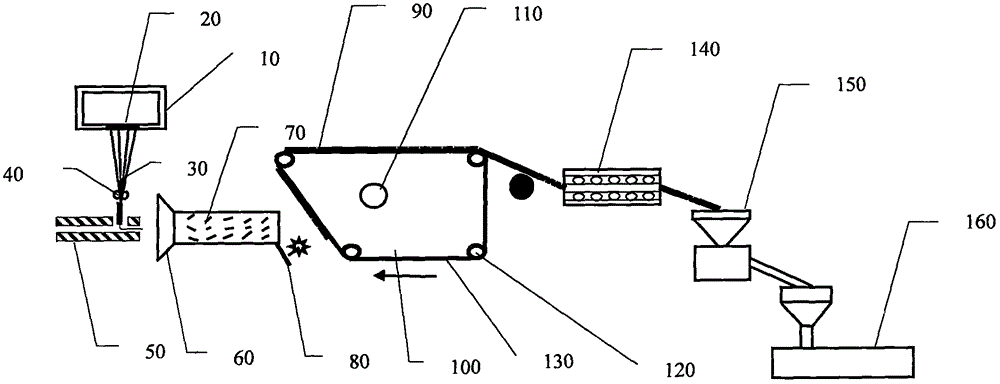

Image

Examples

Embodiment 1

[0031]A glass fiber / thermoplastic granule, composed of glass fiber, thermoplastic and additives, the granule is rod-shaped, with a size of 5mm, and the volume percentage of fiber in the granule is 45%.

[0032] The additives include: cyclohexanone and tetrahydrofuran dissolving agent, isooctyl trimercaptoacetate antimony stabilizer, glycerol ester plasticizer, N-methylol acrylamide crosslinking agent, polyethylene glycol ester lubricant and tricresyl phosphate flame retardant.

[0033] The present invention also provides a method for preparing glass fiber / thermoplastic particles, which is characterized in that it comprises the following steps:

[0034] (1) Dissolve thermoplastics in cyclohexanone and tetrahydrofuran dissolvers, gradually add isooctyl trimercaptoacetate antimony stabilizer, glyceryl glyceride plasticizer, N-methylolacrylamide crosslinking agent, polyethylene glycol Glycol ester lubricant and tricresyl phosphate flame retardant were uniformly mixed to make a pl...

Embodiment 2

[0042] A glass fiber / thermoplastic granule, composed of glass fiber, thermoplastic and additives, the granule is rod-shaped or spherical, with a size of 7mm, and the volume percentage of fiber in the granule is 40%.

[0043] The additives include: cyclohexanone and tetrahydrofuran dissolving agent, isooctyl trimercaptoacetate antimony stabilizer, glycerol ester plasticizer, N-methylol acrylamide crosslinking agent, polyethylene glycol ester lubricant and tricresyl phosphate flame retardant.

[0044] The present invention also provides a method for preparing glass fiber / thermoplastic particles, which is characterized in that it comprises the following steps:

[0045] (1) Dissolve thermoplastics in cyclohexanone and tetrahydrofuran dissolvers, gradually add isooctyl trimercaptoacetate antimony stabilizer, glyceryl glyceride plasticizer, N-methylolacrylamide crosslinking agent, polyethylene glycol Glycol ester lubricant and tricresyl phosphate flame retardant were evenly mixed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com