A kind of preparation method of hydrolysis-resistant aluminum nitride powder

An aluminum nitride and anti-hydrolysis technology, applied in the field of inorganic functional materials, can solve the problems of environmental pollution, poor uniformity, and increase the transportation and storage costs of AlN powder, and achieve the effect of fine and uniform powder particles and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

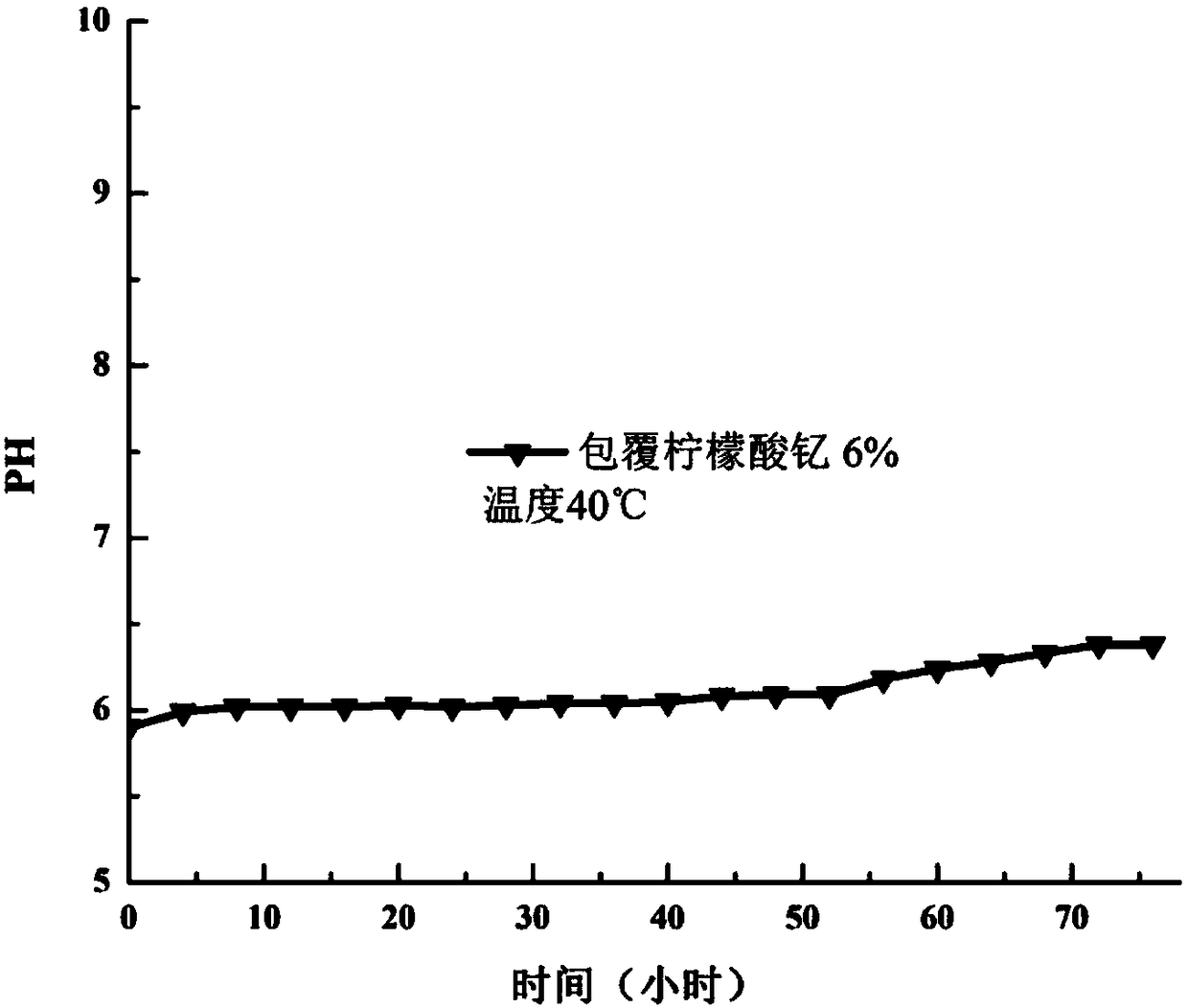

[0022] Weigh 10g of AlN powder, impregnate the AlN powder with 69% (mass percentage concentration, the same below) concentrated nitric acid for 0.5h to carry out passivation treatment; 2 o 3 Put it in a beaker, add nitric acid, and magnetically stir to dissolve it completely to obtain a saturated lanthanum nitrate solution; add the impregnated AlN to the saturated lanthanum nitrate solution and stir evenly; Fully stir at 50°C for 2 hours to obtain rare earth sol and evenly coat AlN powder; use a spray dryer with an outlet temperature of 90°C, a feed rate of 500mL / h, and a blast speed of 0.6m 3 / min drying to obtain aluminum nitride powder coated with lanthanum citrate.

[0023] The aluminum nitride powder obtained in this example does not undergo hydrolysis in water at 40° C. for 40 hours.

Embodiment 2

[0025] Weigh 10g AlN powder, impregnate AlN powder with 69% concentrated nitric acid for 3h for passivation treatment; 0.3g La 2 o 3 Place in a beaker, add nitric acid, and magnetically stir to dissolve it completely to obtain a saturated lanthanum nitrate solution; add the impregnated AlN to the saturated lanthanum nitrate solution and stir evenly; then add 0.36g citric acid and 0.14g ethylene glycol, Fully stir in a water bath at 60°C for 1 hour to obtain a rare earth sol and evenly coat the AlN powder; use a spray dryer with an outlet temperature of 90°C, a feed rate of 500mL / h, and a blast speed of 0.6m 3 / min drying to obtain aluminum nitride powder coated with lanthanum citrate.

[0026] The aluminum nitride powder obtained in this example does not undergo hydrolysis in water at 40° C. for 43 hours.

Embodiment 3

[0028] Weigh 10g AlN powder, impregnate AlN powder with 69% concentrated nitric acid for 6h for passivation treatment; 0.6g La 2 o 3 Place in a beaker, add nitric acid, and magnetically stir to dissolve it completely to obtain a saturated lanthanum nitrate solution; add the impregnated AlN to the saturated lanthanum nitrate solution and stir evenly; then add 0.71g citric acid and 0.28g ethylene glycol, Fully stir in a water bath at 80°C for 0.5h to obtain a rare earth sol and evenly coat the AlN powder; use a spray dryer with an outlet temperature of 90°C, a feed rate of 500mL / h, and a blast speed of 0.6m 3 / min drying to obtain aluminum nitride powder coated with lanthanum citrate.

[0029] The aluminum nitride powder obtained in this example does not undergo hydrolysis in water at 40° C. for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com