A microwave-assisted method for sorting recycled concrete coarse aggregate

A recycled concrete and microwave-assisted technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem that the quality of recycled concrete aggregate is difficult to guarantee, it is not suitable for large-scale production of recycled concrete aggregate, and the efficiency of selection Low-level problems, to achieve the effect of reducing the difficulty of crushing machinery crushing, protecting the original quality, and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

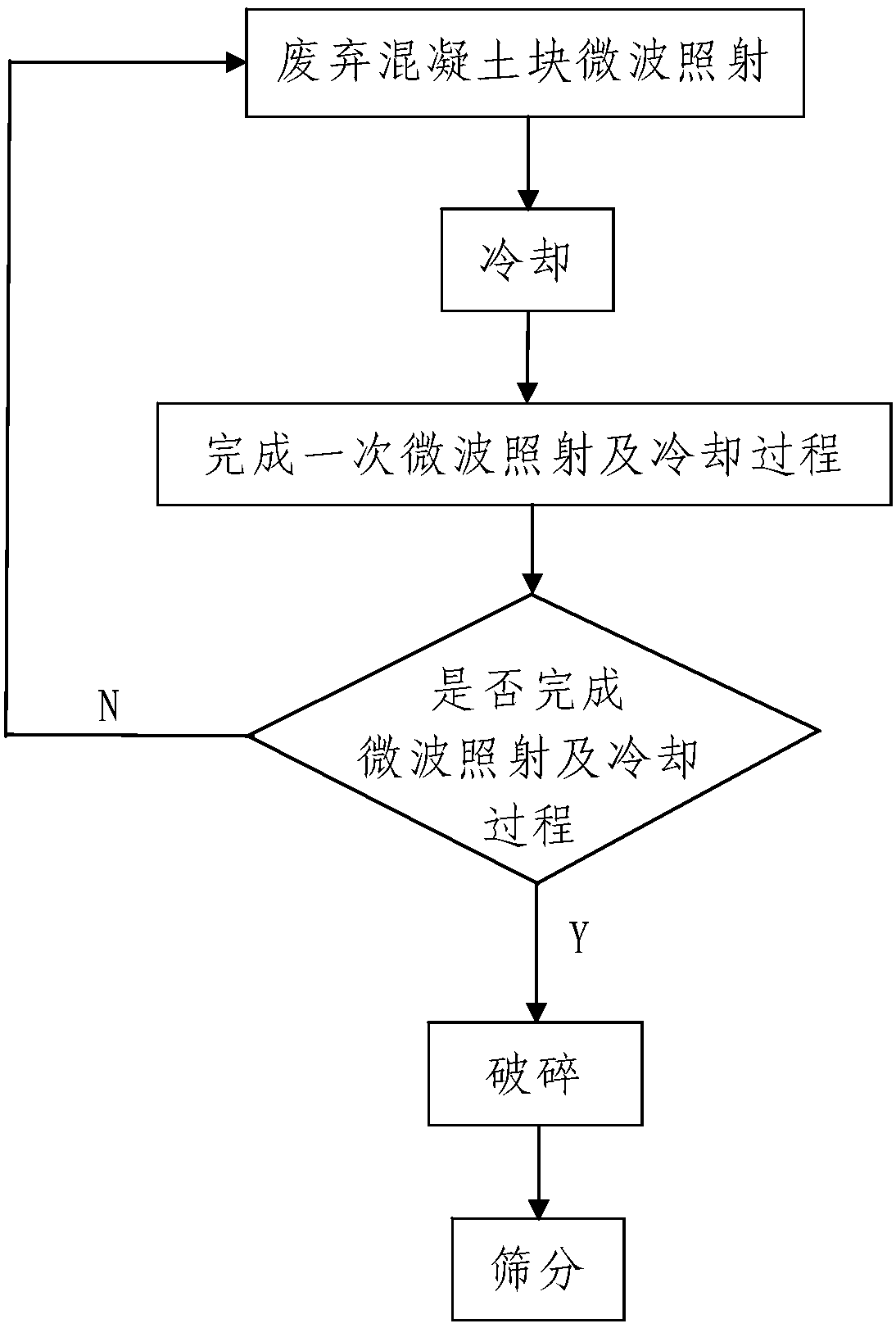

[0048] Such as figure 1 A microwave-assisted method for selecting recycled concrete coarse aggregate comprises the following steps:

[0049] Step 1, microwave irradiation and cooling, the process is as follows:

[0050] Step 101, the first microwave irradiation and cooling includes the following steps:

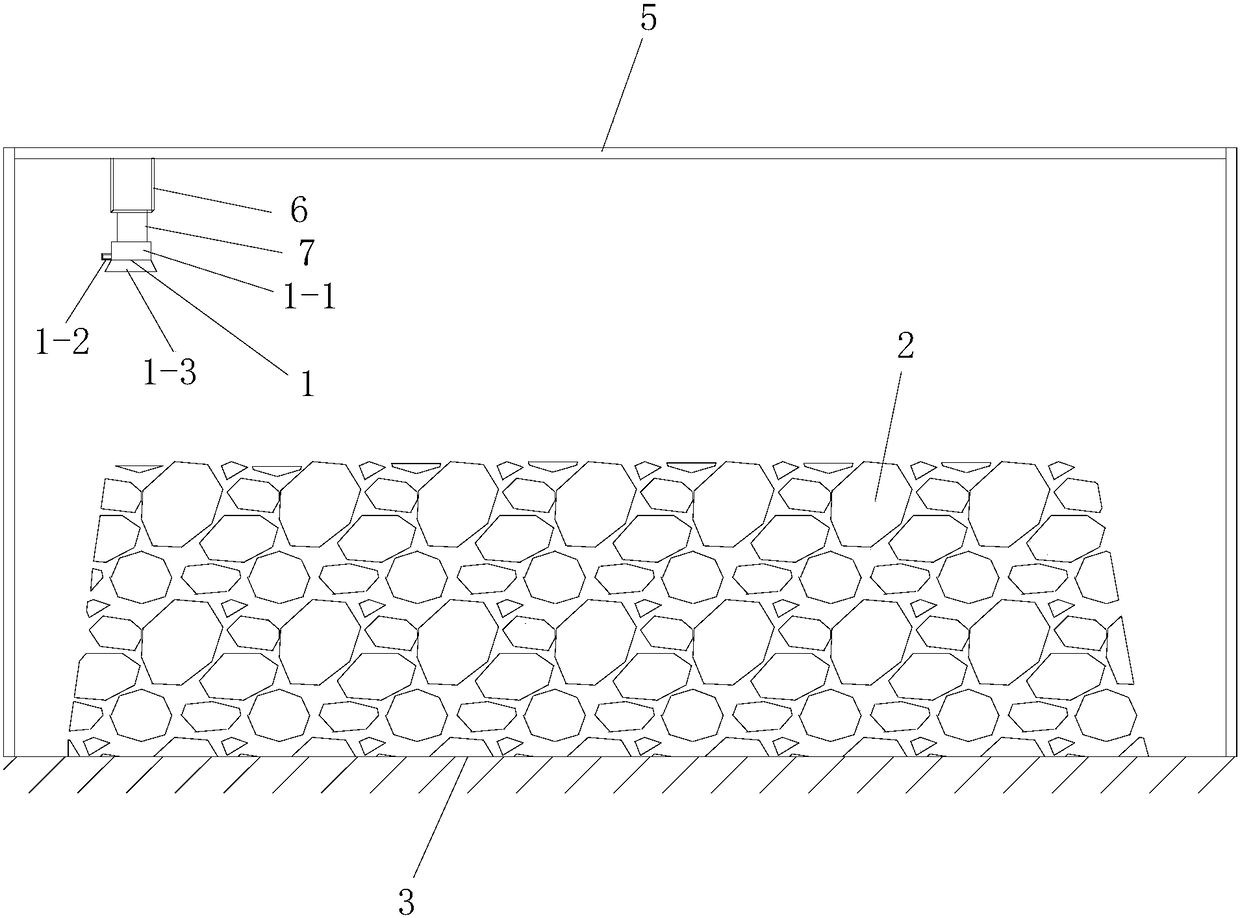

[0051] Step 1011, microwave irradiation of waste concrete blocks: after transporting waste concrete blocks 2 and stacking them in microwave irradiation area 3, use microwave emitting device 1 to carry out microwave irradiation on waste concrete blocks 2, the irradiation height is 1.5m, and the irradiation time is 5 minutes;

[0052] The microwave emitting device 1 is arranged above the microwave irradiation area 3, and the power of the microwave emitted by the microwave emitting device 1 is 5kw; the stacking height of the waste concrete blocks 2 is not greater than 1.5m;

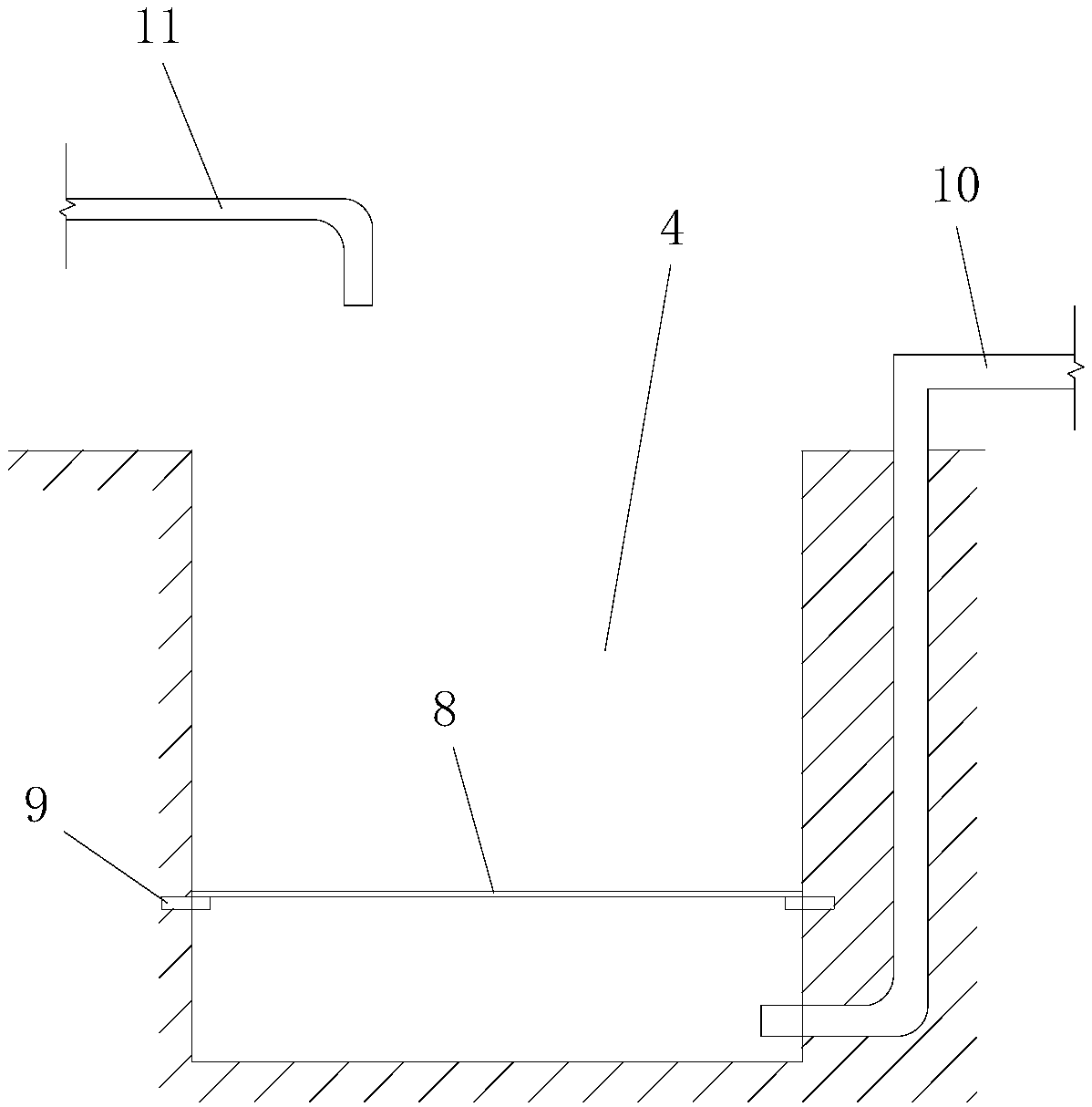

[0053] Step 1012, cooling: transport the waste concrete blocks 2 irradiated by microwaves in step 1011 ...

Embodiment 2

[0103] In this embodiment, different from Embodiment 1, the irradiation height in step 1011 is 1m, the irradiation time is 8min and the power of the microwave emitted by the microwave transmitting device 1 is 5.5kw, and the cooling time in step 1012 is 1min, that is, in step 10123 The soaking time is 1 min; N=2 in step 103; the sieve aperture of the screening equipment in step 3 is Φ40mm.

[0104] In this embodiment, the remaining method steps and parameters are the same as those in Embodiment 1.

Embodiment 3

[0106] In this embodiment, the difference from Embodiment 1 is that in step 1011, the irradiation height is 1.2m, the irradiation time is 3min and the power of the microwave emitting device 1 is 5.5kw, and the cooling time in step 1012 is 3min, that is, step 10123 The soaking time in medium is 3min; the sieve hole diameter of the screening equipment described in step 3 is Φ10mm.

[0107] In this embodiment, the remaining method steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com