Modification method for jet printing base material pet for RFID label antenna based on particle-free type conductive ink

A technology of RFID tags and conductive inks, which is applied in the field of electronic tags, can solve the problems of RFID tag antenna printing inconvenience, no patent publications have been found, RFID tag antenna inconvenience, etc., to achieve increased adhesion, simple method, and improved pet surface sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

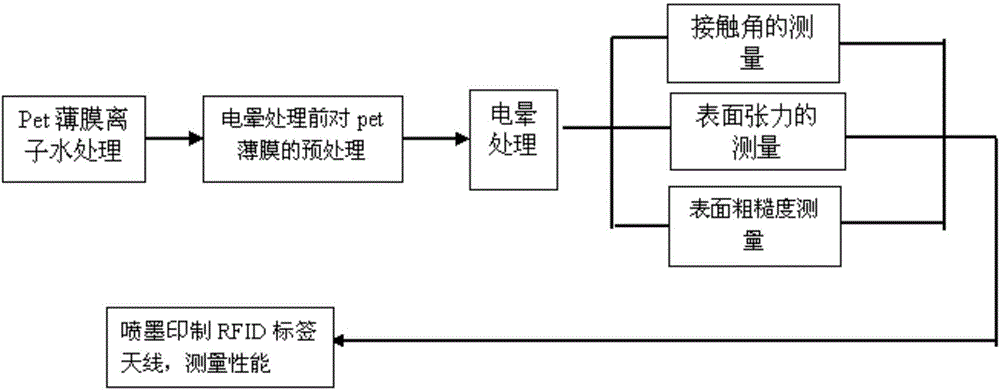

[0023] A modification method based on particle-free conductive ink inkjet printing RFID tag antenna substrate PET, the specific steps are as follows:

[0024] ⑴Pet film pretreatment before corona treatment: After the pet film is washed with deionized water, it is extracted in a mixed solution of alcohol, ethyl acetate and acetone for 24 hours to remove oil and dust on the surface of the pet. Dry it in a vacuum oven for later use, and get the processed pet film;

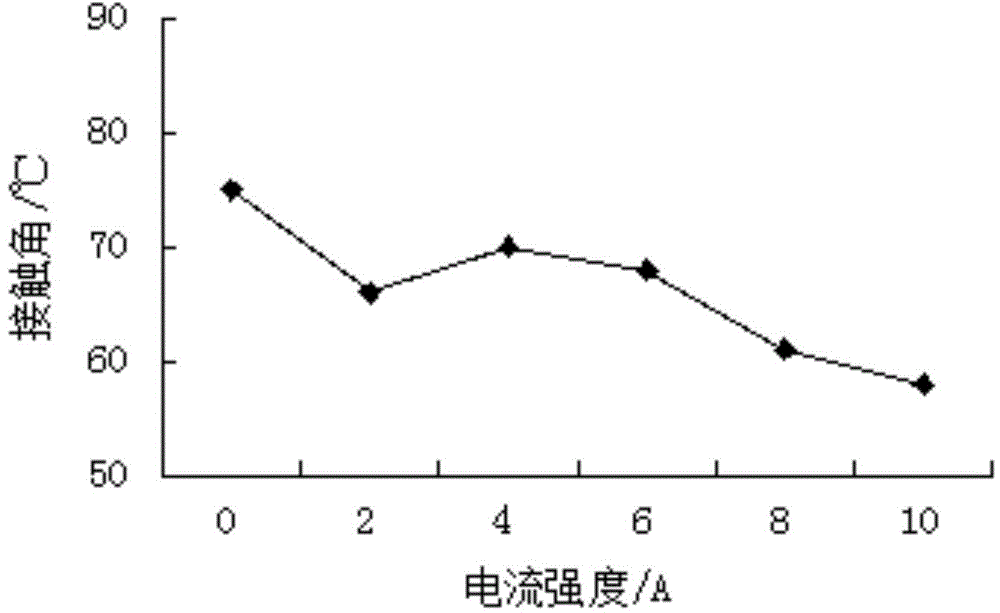

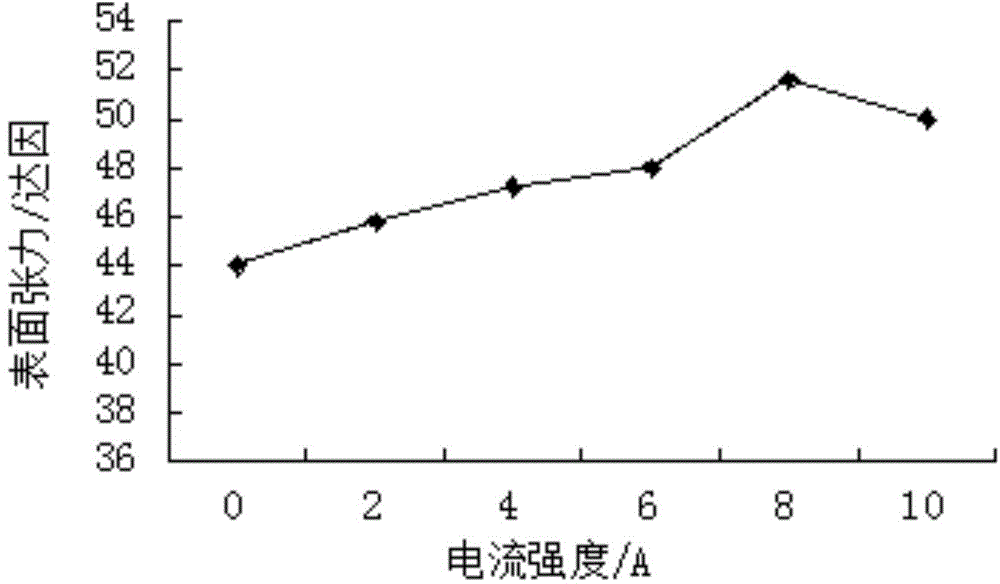

[0025] (2) Preheat the treated pet film to 30°C, and perform corona treatment on a corona treater with a current intensity of 2-10A at a speed of 8m / min under a stable power of 10kw to obtain a modified pet film;

Embodiment 2

[0027] A modification method based on particle-free conductive ink inkjet printing RFID tag antenna substrate PET, characterized in that: the specific steps are as follows:

[0028] ⑴Pet film pretreatment before corona treatment: After the pet film is washed with deionized water, it is extracted in a mixed solution of alcohol, ethyl acetate and acetone for 24 hours to remove oil and dust on the surface of the pet. Dry it in a vacuum oven for later use, and get the processed pet film;

[0029] (2) Preheat the treated pet film to 35°C, and perform corona treatment on a corona treatment machine with a current intensity of 7A at a speed of 10m / min under a stable power of 14kw to obtain a modified pet film;

Embodiment 3

[0031] A modification method based on particle-free conductive ink inkjet printing RFID tag antenna substrate PET, the specific steps are as follows:

[0032] ⑴Pet film pretreatment before corona treatment: After the pet film is washed with deionized water, it is extracted in a mixed solution of alcohol, ethyl acetate and acetone for 24 hours to remove oil and dust on the surface of the pet. Dry it in a vacuum oven for later use, and get the processed pet film;

[0033] (2) Preheat the treated pet film to 40°C, and perform corona treatment on a corona treatment machine with a current intensity of 10A at a speed of 15m / min under a stable power of 18kw to obtain a modified pet film;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com