Novel dry type machining grinding tool and preparation method thereof

An abrasive, dry technology, applied in the field of grinding, can solve the problems of sintering temperature sensitivity, decreased abrasive hardness, easy blockage and heat generation, etc., and achieves the effect of improving high temperature sintering performance, improving yield strength and good oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

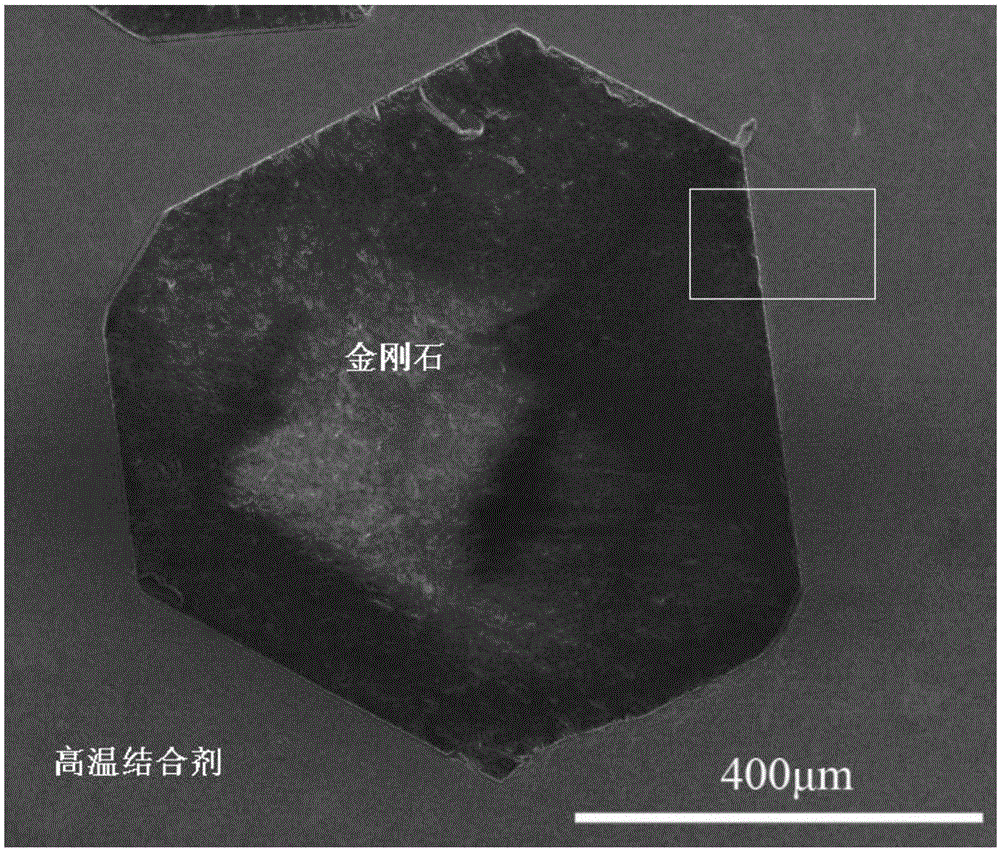

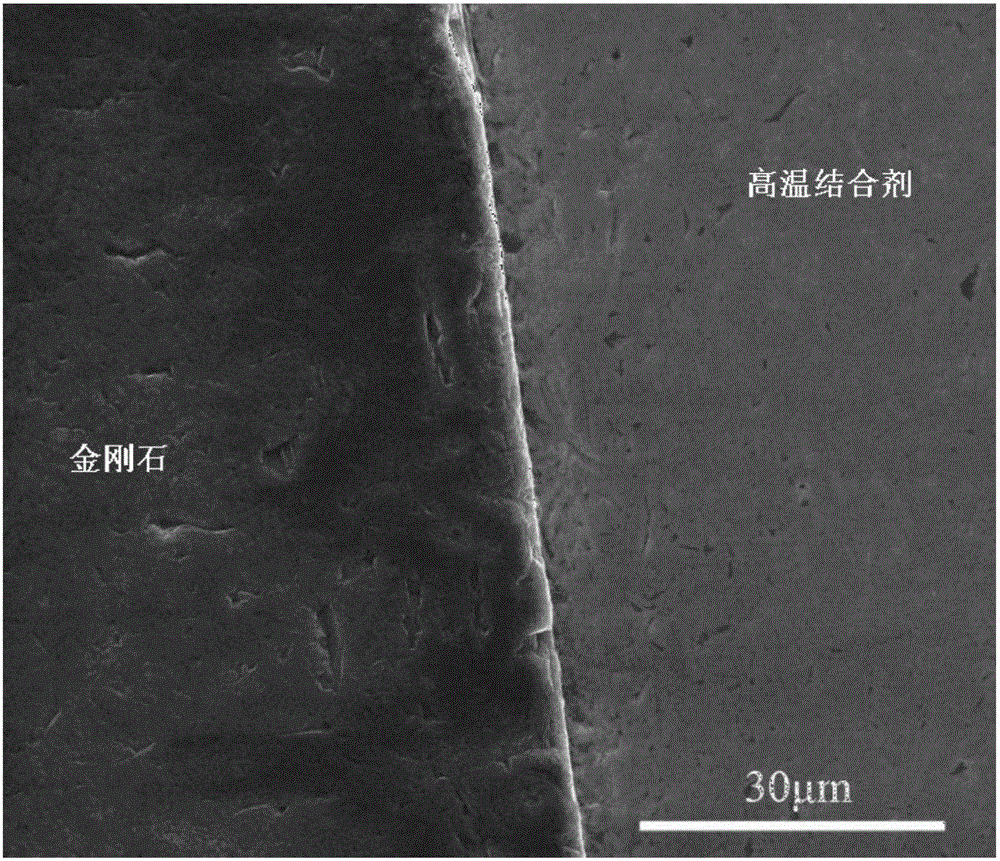

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of novel dry processing abrasive tool, comprises the following steps:

[0037] A) high-temperature bonding agent, common bonding agent and abrasive are carried out ball milling, obtain abrasive compound; Described high-temperature bonding agent comprises Ni 3 Al powder;

[0038] One or more of the common binder nickel-based binder, copper-based binder, iron-based binder and cobalt-based binder;

[0039] B) cold-pressing the abrasive compound to obtain a green body;

[0040] C) Sintering the green body to obtain a new type of dry machining abrasive.

[0041] In the present invention, it is preferred to mix and ball-mill the high-temperature bonding agent and common bonding agent to obtain the bonding agent mixture, and then ball mill the bonding agent mixture and abrasive material to obtain the abrasive tool mixture. In the present invention, the composition, particle size and dosage of the high-temperat...

Embodiment 1

[0050] 90 parts of Ni with a particle size of 6 μm 3 Al powder and 6 parts of cobalt-based pre-alloyed powder with a particle size of 20 μm are mixed and ball milled to obtain a binder mixture. The ball mill speed is 200r / min, the ball milling time is 20min, and the ball to material ratio is 10:1;

[0051] Ball mill 96 parts of the binder mixture and 4 parts of diamond abrasives with a particle size of 30-40 meshes to make them evenly mixed to obtain the abrasive mixture. The rotating speed of the ball mill is 200r / min, the ball milling time is 20min, and the ball-to-material ratio is 5:1.

[0052] Putting the abrasive mixture into a cold-pressing mold for cold-pressing to obtain an abrasive body. The compact density of the mold is 50% of theoretical density.

[0053] Carry out hot pressing sintering to the mold body, the sintering maximum temperature is 900°C, and the heat preservation is 25min. Pressure is 50Mpa, obtain superhard abrasive tool.

[0054] The present inven...

Embodiment 2

[0056] 80 parts of Ni with a particle size of 5 μm 3 Al powder and 14 parts of copper-based pre-alloyed powder with a particle size of 25 μm were mixed and ball-milled to obtain a binder mixture.

[0057] 94 parts of the binder mixture and 6 parts of diamond abrasives with a particle size of 40-50 meshes are ball-milled to make them evenly mixed to obtain the abrasive mixture. The rotating speed of the ball mill is 250r / min, the ball milling time is 15min, and the ball-to-material ratio is 10:1.

[0058] Putting the abrasive mixture into a cold-pressing mold for cold-pressing to obtain an abrasive body. The compact density of the mold is 50% of theoretical density.

[0059] Carry out hot pressing sintering to the mold body, the sintering maximum temperature is 1000°C, and the heat preservation is 20min. Pressure is 50Mpa, obtain superhard abrasive tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com