A floating breakwater device

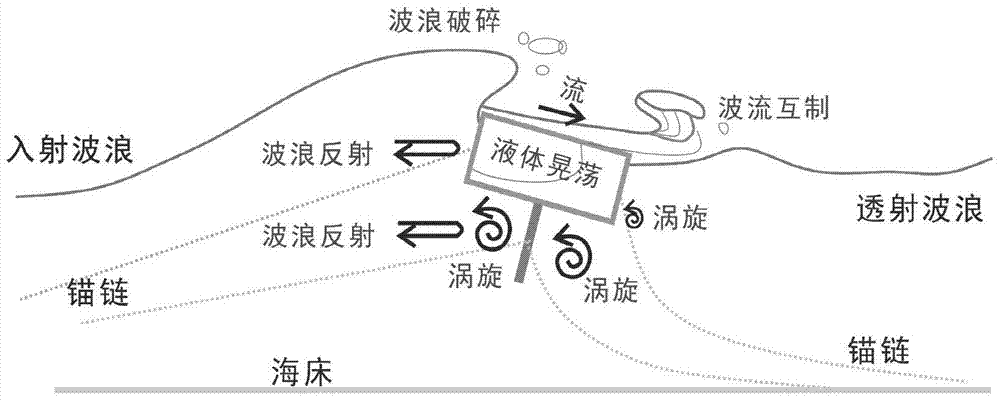

A floating breakwater and box technology, applied in the field of marine engineering, can solve the problems of unsuitable adaptability and durability, limited depth of water entry, and shortened service life, and achieve the effects of easy molding, improved wave elimination performance, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

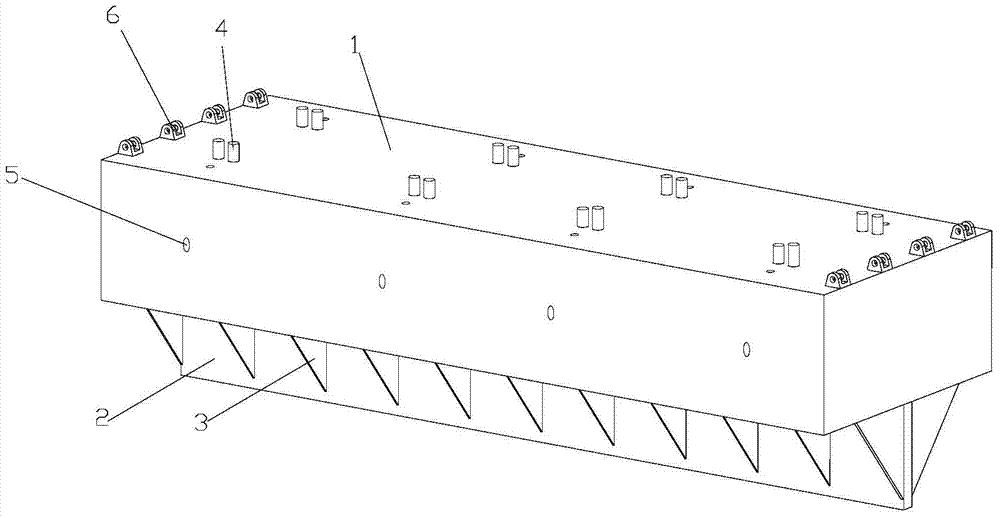

[0023] Such as figure 1 As shown, a floating breakwater device includes a floating unit and an anchoring system for constraining the floating unit; the floating unit includes a box body 1, a rib plate 3 and a web plate 2 arranged at the bottom of the box body 1, The web 2 is arranged along the length direction of the box body 1 and is perpendicular to the bottom surface of the box body 1 . The rib plate 3 is arranged along the width direction of the box body 1 and connects the box body 1 and the web plate 2 .

[0024] The mooring system includes an anchor chain and an anchor pier arranged at the bottom of the anchor chain, bollards 4 are arranged on both sides of the upper surface of the box body 1, and a cable hole 5 is arranged on the box body 1, and the cable The hole 5 runs through the side surface and the upper surface of the box body 1 and corresponds to the position of the bollard 4 , and the anchor chain passes through the cable hole 5 and is connected with the bollard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com