A kind of heavy oil hydrogenation processing method

A technology of heavy oil hydrogenation and treatment method, which is applied in refining to remove heteroatoms, etc., to achieve good hydrodesulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The pseudo-boehmite dry rubber powder RPB90 produced by 1 kilogram of Changling Catalyst Factory and 30 grams of fennel powder are mixed uniformly, and at room temperature, the concentration of this mixture and 1.1 liters is 1% by weight of nitric acid aqueous solution, mix uniformly, After continuing to knead into a plastic body on a twin-screw extruder, extrude it into a trefoil strip of ф1.1mm, dry the wet strip at 120°C for 3 hours, and then calcinate it at 600°C for 3 hours to obtain a shaped alumina carrier ZII1. The physical and chemical results of the determination of ZII1 are shown in Table 1.

Embodiment 2

[0052] Mix 1 kilogram of pseudo-boehmite dry rubber powder RPB100 produced by Changling Catalyst Factory and 30 grams of astragalus powder evenly, add 1.2 liters of nitric acid aqueous solution with a concentration of 1% by weight, mix evenly, and continue kneading on the twin-screw extruder After forming a plastic body, it is extruded into a butterfly-shaped strip of ф1.1mm, and the wet strip is dried at 110°C for 2 hours, and then calcined at 700°C for 3 hours to obtain a shaped alumina carrier ZII2. The physical and chemical results of the determination of ZII2 are shown in Table 1.

Embodiment 3

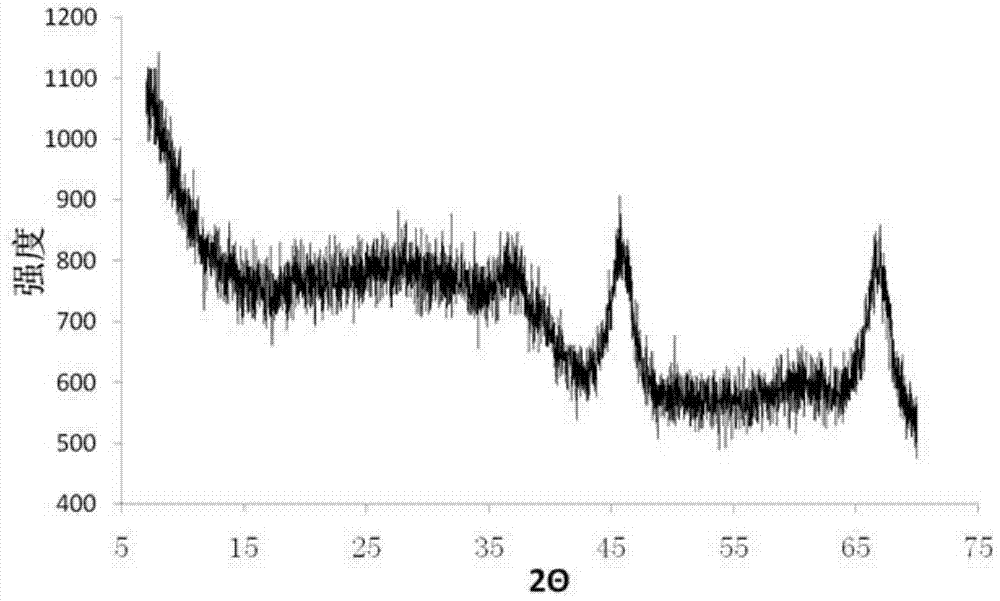

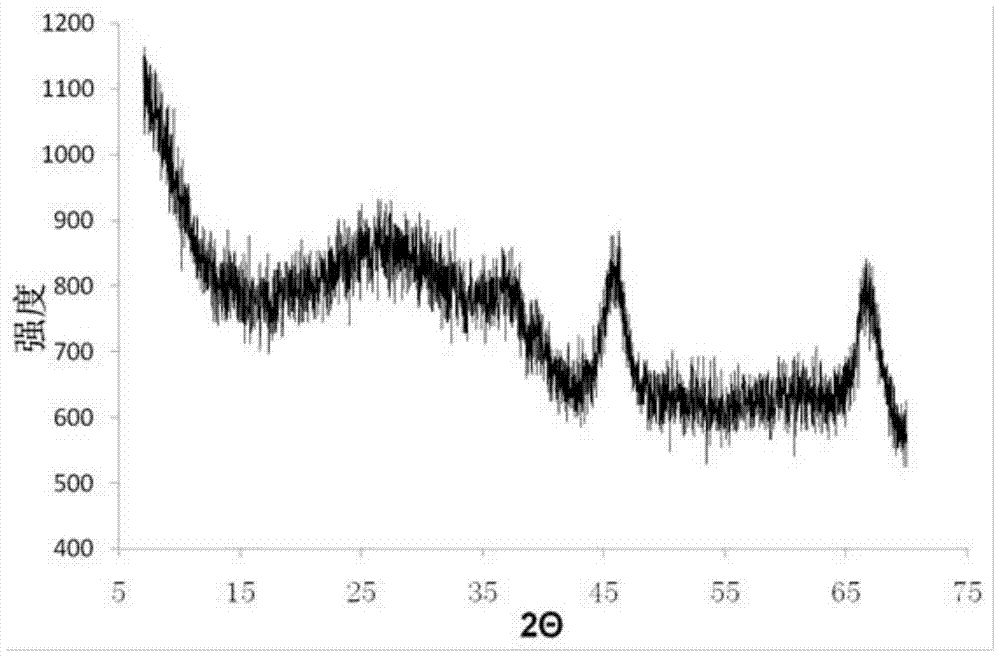

[0055] Weigh 150g of the ZII1 carrier and place it in a hydration kettle, add 150g of deionized water, seal the hydration kettle and put it in an oven, heat it with a programmed temperature rise, and control the temperature rise rate to 10°C·min -1 , the treatment temperature is 80° C., and the treatment time is 16 hours. After the completion of the hydrothermal treatment, the alumina was filtered, and then dried at 120° C. for 3 hours to obtain a hydrothermally treated alumina carrier.

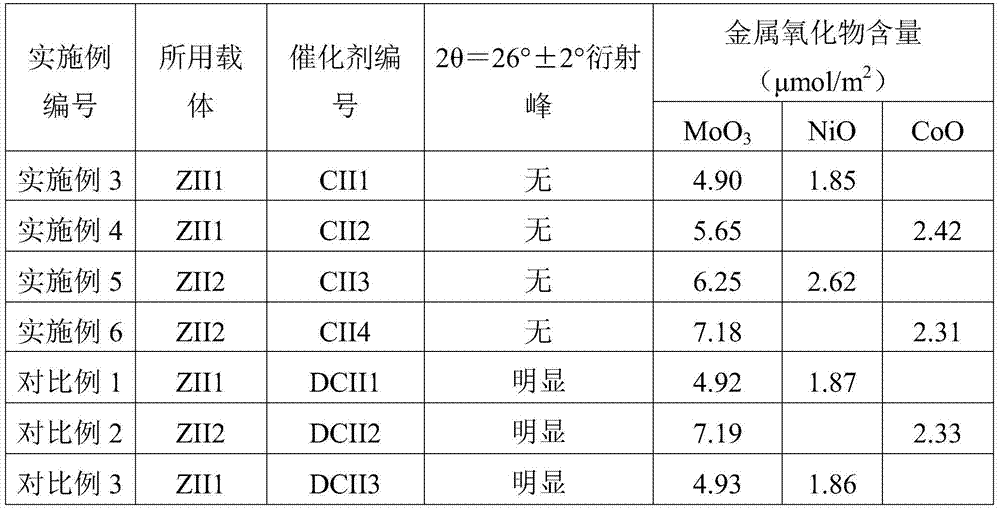

[0056] Take 100 grams of carrier ZII1 after heat treatment in water, and use 220 ml of MoO 3 170 g / L, NiO 30 g / L mixed solution of ammonium molybdate and nickel nitrate was impregnated for 1 hour, filtered, dried at 120°C for 2 hours, and calcined at 410°C for 2 hours to obtain catalyst CII1. In terms of oxides and based on the load on the surface of the unit carrier II, an X-ray fluorescence spectrometer is used to measure the content of molybdenum oxide and nickel oxide in the catalyst CI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com