A kind of heavy oil hydrogenation processing method

A technology for heavy oil hydrogenation and treatment methods, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve good hydrodesulfurization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention first provides a reference preparation method of the carrier I in the heavy oil hydrotreating catalyst I, and the method may include:

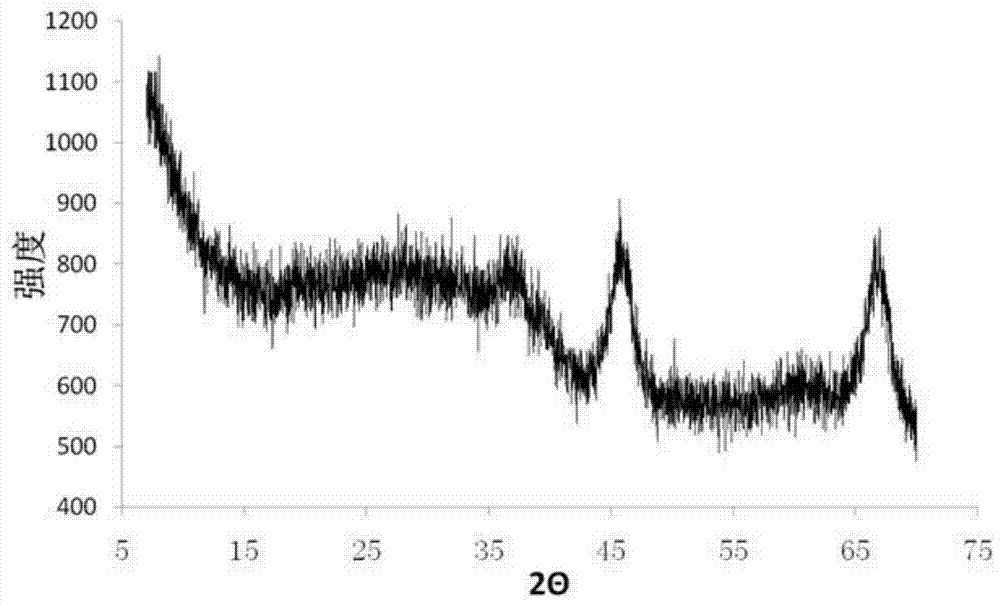

[0030] (1) A pseudo-boehmite with a large pore size and a high pore volume is prepared by reacting an aqueous solution of sodium metaaluminate and / or sodium aluminate with an acidic solution and then aging, washing and drying; the conditions of the reaction include : The reaction pH is 4.5-9, preferably 5.5-8.5, and the reaction temperature is 15-75°C, preferably 20-60°C; the aging conditions include: adding an aging agent, and the aging temperature is 15-75°C, preferably 20-60°C, the aging time is 0.5-8 hours, preferably 2-6 hours, the aging agent is at least one selected from the group consisting of ammonium carbonate, ammonium bicarbonate, ammonium carbonate aqueous solution and ammonium bicarbonate aqueous solution, preferably Ammonium carbonate aqueous solution; the washing is a conventional method, whose purpose...

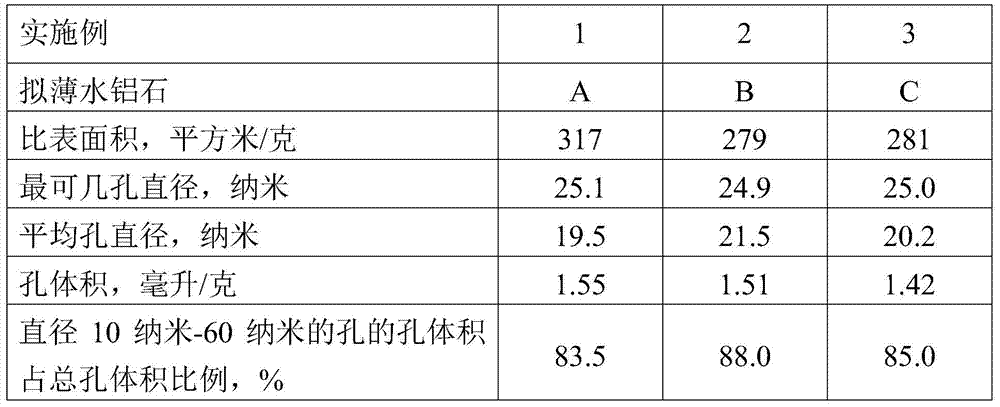

Embodiment 1

[0053] Weigh 483 grams of aluminum chloride (product of Beijing Chemical Plant), add deionized water to dissolve it into a solution a1 with a molar concentration of 1 mol / L; weigh 210 grams of sodium metaaluminate (product of Tianjin Jinke Fine Chemical Research Institute), Add deionized water to dissolve into a solution b1 with a molar concentration of 3.0 mol / L; weigh 230 grams of ammonium carbonate (product of Beijing Chemical Reagent Company), and add deionized water to dissolve into a solution c1 with a molar concentration of 0.5 mol / L. Add solution a1 and solution b1 to a 10 liter gelling tank in a parallel flow to react, control the flow rate of solution a1 and solution b1, and make the pH value of the reaction process 8.5 and gel forming temperature of 60℃. After completion, add solution c1, age at 60°C for 2.5 hours, filter, wash the filter cake with 10 liters of 60°C deionized water, and dry it in a drying oven at 150°C for 2 hours to obtain pseudo-boehmite A, 600°C A...

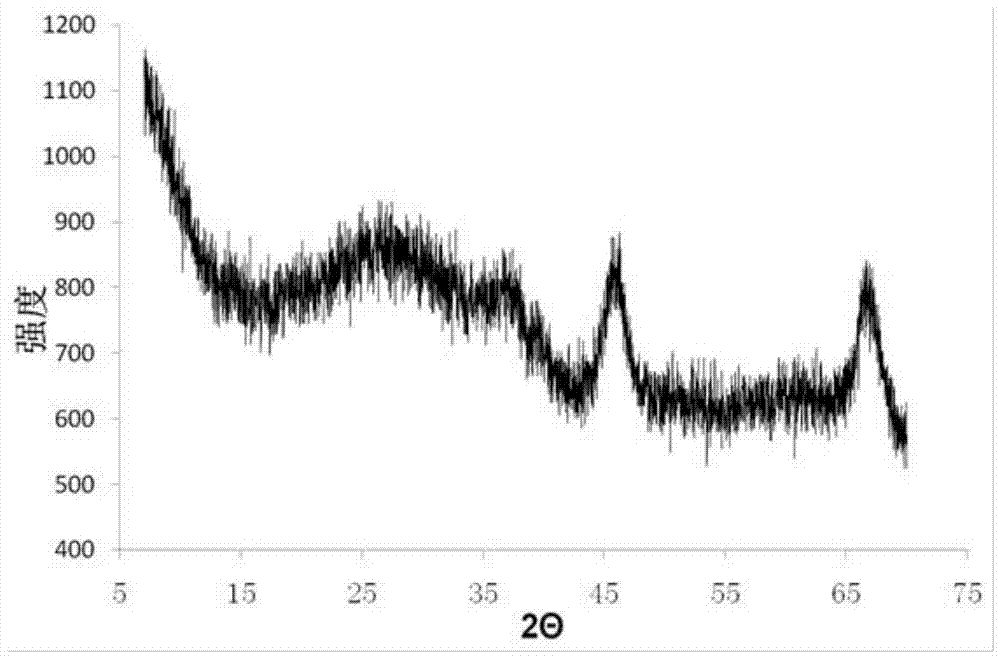

Embodiment 2

[0055] Weigh 666 grams of aluminum sulfate (product of Beijing Chemical Plant) and add deionized water to dissolve it into solution a2 with a molar concentration of 0.5 mol / L; Weigh 210 grams of sodium metaaluminate (product of Tianjin Jinke Fine Chemical Research Institute), Add deionized water to dissolve into a solution b2 with a molar concentration of 2.0 mol / L; weigh 370 grams of ammonium bicarbonate (product of Beijing Chemical Reagent Company), and add deionized water to dissolve into a solution c2 with a molar concentration of 1.0 mol / L. Add solution a2 and solution b2 into a 10 liter gelling tank in parallel flow at the same time, and control the flow rate of solution a2 and solution b2 to make the pH value of the reaction process 6.0 and the gel forming temperature 40℃. After completion, add solution c2, age at 40°C for 6 hours, filter, wash the filter cake with 15 liters of deionized water at 40°C, and dry it in a drying oven at 100°C for 6 hours to obtain pseudo-boeh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com