A kind of heavy oil hydrotreating method

A technology of heavy oil hydrogenation and treatment method, which is applied in refining to remove heteroatoms, etc., to achieve good hydrodesulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

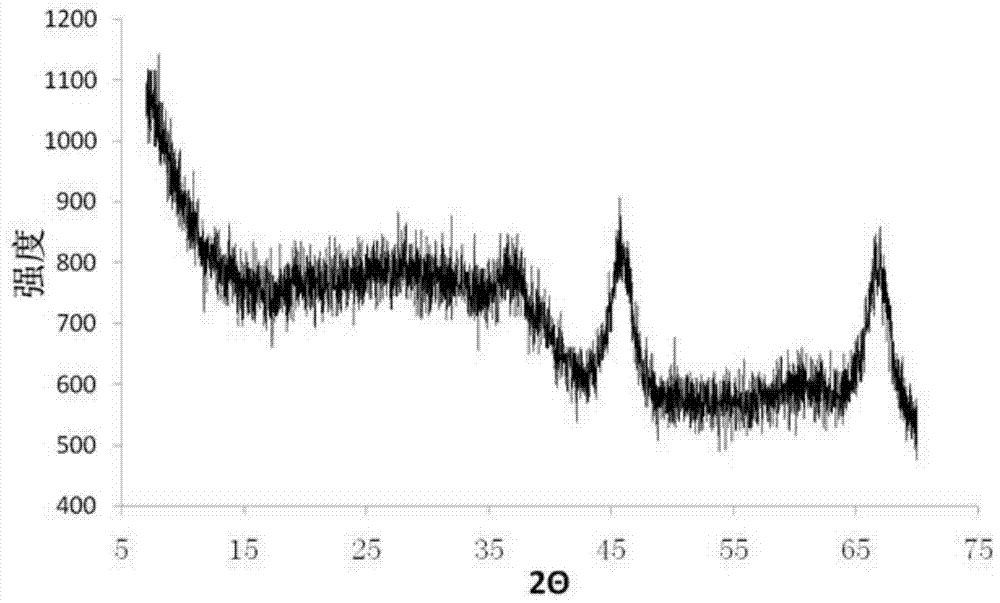

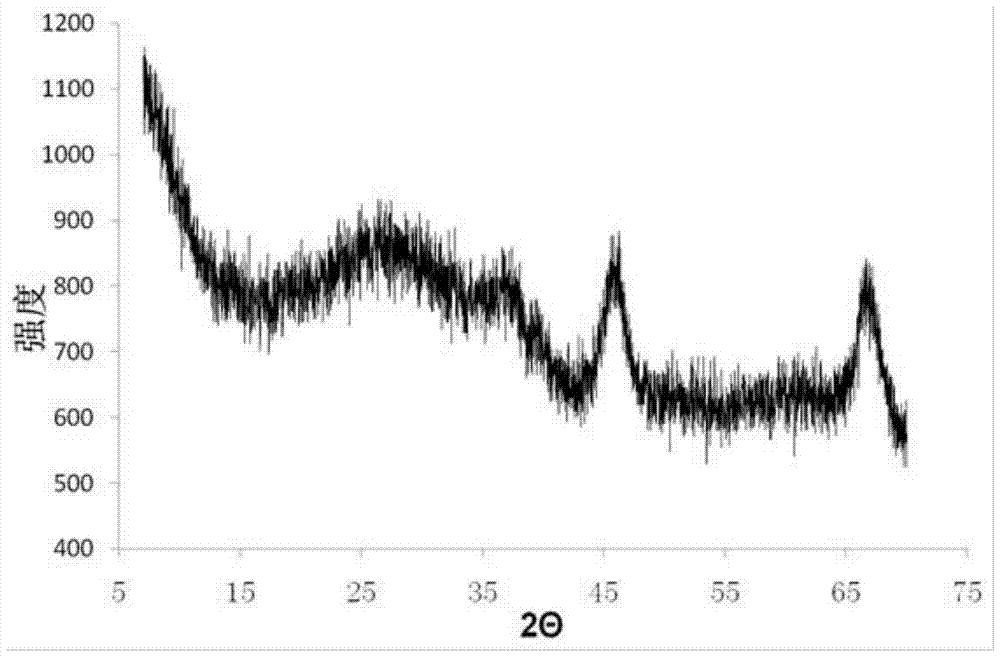

Image

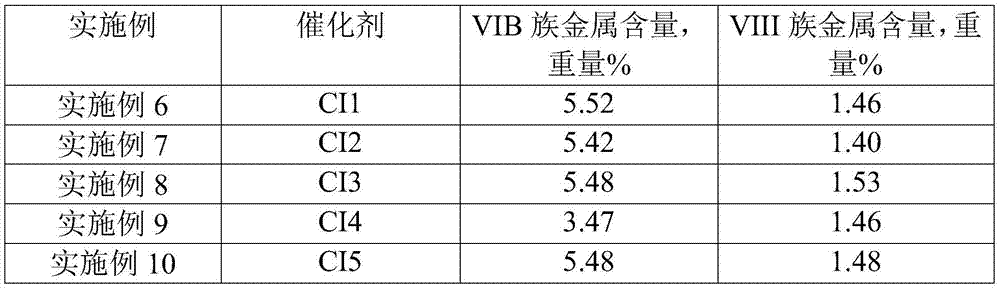

Examples

preparation example Construction

[0030] The present invention firstly provides a reference preparation method of the carrier I in the heavy oil hydrotreating catalyst I, the method comprising: mixing a hydrated alumina with an α-alumina and introducing boron-containing compound, then shaped, dried and fired. The temperature of the calcination can be 750-1000°C, preferably 800-950°C; the time of the calcination is 1-10 hours, preferably 2-8 hours; wherein, the hydrated alumina and α- The mixing weight ratio of alumina is 0.25-4, preferably 0.5-2. The method of introducing a boron-containing compound into the mixture of the hydrated alumina and the α-alumina is a conventional method, which can be directly adding the required amount of the boron-containing compound in the hydrated alumina and the α-alumina During the mixing process, for example, an aqueous solution prepared by a boron-containing compound can be introduced into the mixture of the hydrated alumina and the α-alumina, and the aqueous solution is mi...

Embodiment 1

[0054] Take by weighing 200g hydrated alumina (commercially purchased from Changling Catalyst Branch Company, the dry basis is 65% by weight, the pore volume is 1.05 ml / g, and the specific surface area is 230 m 2 / gram, the diameter of the most possible holes is 20 nanometers), 70 grams of α-alumina powder (formed by roasting 6 hours at 1400° C. by the hydrated alumina used in this embodiment), 9 grams of scallop powder and 15 grams of borax Mixing, at room temperature, this mixture is mixed with 330 milliliters of ammonia solution with a concentration of 4% by weight, after mixing evenly, kneading in a twin-screw extruder and extruding with a cylindrical orifice of φ 2.0mm, after that, the wet strip is passed through After drying at 120°C for 4 hours, calcining at 850°C for 2 hours, the carrier ZI1 of the present invention was obtained. The specific surface, most probable pore diameter, pore volume, pore distribution and boron content of carrier ZI1 were measured, and the res...

Embodiment 2

[0056] Take by weighing 180g dry rubber powder (commercially purchased from Changling Catalyst Branch Company, the dry basis is 65% by weight, the pore volume is 1.05 ml / g, the specific surface area is 285 m2 / g, and the most probable pore diameter is 20 nanometers), 120 grams of α-alumina powder (commercially purchased in Beijing Shun Chuan Environmental Protection Technology Co., Ltd.), 9 grams of scallop powder and 8 grams of boron oxide are mixed, then add 330 milliliters of aqueous solutions containing 10 grams of sodium borate, and mix them uniformly in a twin-screw screw Kneading in the extruder and extruding with a φ2.0mm cylindrical orifice, after that, the wet strip was dried at 120°C for 4 hours and then calcined at 850°C for 2 hours to obtain the carrier ZI2 of the present invention. The specific surface, most probable pore diameter, pore volume, pore distribution and boron content of carrier ZI2 were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com