Ozone catalytic ozonation tower and gasified waste water treatment method utilizing same

A technology of ozone catalysis and oxidation tower, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of cumbersome process, high investment and operation cost, and achieve simple process and low operation The effect of cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

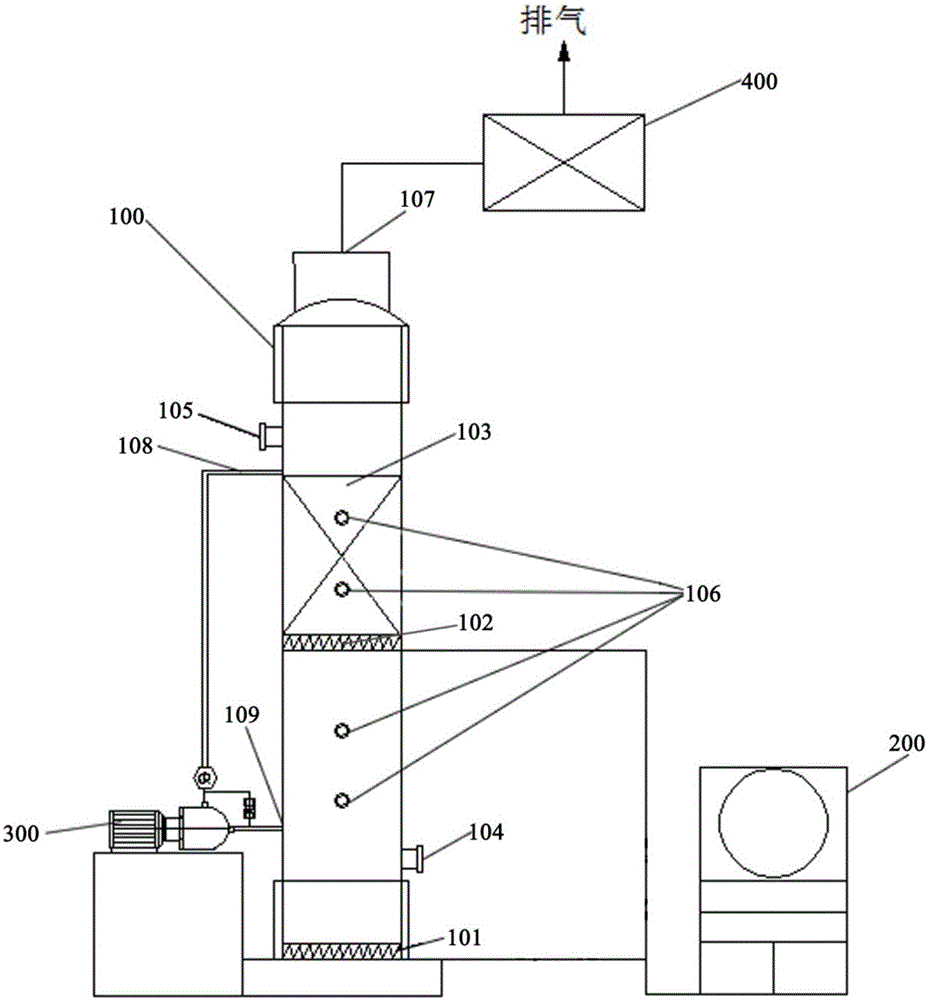

Image

Examples

Embodiment 1

[0049] Carrier pretreatment step, select coal-based columnar activated carbon (diameter 6mm, specific surface area ≥ 800m 2 / g, compressive strength > 96N, bulk density > 0.45g / ml) is the ozone oxidation catalyst carrier material, washed 5 times with water, then soaked in 0.03mol / L dilute nitric acid for 40h, and finally washed with water to supernatant The pH of the liquid is neutral, and it is baked in an oven at 60°C for 48 hours for later use;

[0050] Dipping treatment step, preparation final concentration is respectively the mixed salt solution of 0.60mol / L manganese nitrate, 0.02mol / L nickel nitrate, 0.02mol / L ferric nitrate, 0.05mol / L cerium chloride, 0.08mol / L copper acetate, will Put the pretreated ozone oxidation catalyst carrier material into the above mixed salt solution according to the dosage of 140g / L, shake and impregnate in a water bath at 80°C for 8h, filter out the impregnated material after impregnation, and dry in an oven at 78°C for 28h , repeat the abo...

Embodiment 2

[0053] Carrier pretreatment step, select porous ceramic pellets (particle diameter is 5mm, specific surface area ≥ 240m 2 / g, compressive strength > 140N, bulk density > 0.17g / ml) is the ozone oxidation catalyst carrier material, washed twice with water, then soaked in 0.08mol / L dilute nitric acid for 24h, and finally washed with water to supernatant The pH of the liquid is neutral, and it is baked in an oven at 90°C for 24 hours for later use;

[0054] The impregnation treatment step is to prepare a mixed salt solution of manganese nitrate, nickel nitrate, iron nitrate, cerium nitrate, cobalt nitrate and copper nitrate with a final concentration of 0.10mol / L. Put the dosage of the above mixed salt solution into the above mixed salt solution, shake and impregnate in a water bath at 80°C for 24 hours, filter out the impregnation after the impregnation is completed, dry in an oven at 90°C for 24 hours, repeat the above impregnation operation twice, and set aside;

[0055] In th...

Embodiment 3

[0057] Carrier pretreatment step, select molecular sieve (model is ZSM-5, particle diameter is 6mm, specific surface area ≥ 350m 2 / g, compressive strength > 120N, SiO 2 / Al 2 o 3 25-400, bulk density > 0.75g / ml) is the carrier material of the ozone oxidation catalyst, washed with water for 4 times, then soaked in 0.04mol / L dilute nitric acid for 28 hours, and finally washed with water until the pH of the supernatant is neutral properties, baked in an oven at 65°C for 45 hours for later use;

[0058] Impregnation treatment step, preparing manganese nitrate, 0.60mol / L nickel sulfate, 0.60mol / L ferric chloride, 0.60mol / L cerium sulfate, 0.40mol / L cobalt chloride, 0.40mol / L copper chloride mixed solution, put the pretreated ozone oxidation catalyst support material into the above mixed salt solution according to the dosage of 40g / L, shake and impregnate in a water bath at 85°C for 30h, and use Filter out the impregnation, dry in an oven at 80°C for 24 hours, repeat the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com